Circuit breakers are essential protective equipment in medium-voltage power networks, particularly in industrial & substation settings.

- Circuit Breaker Testing Checklist

- 1. Check Breaker Timings

- 2. Check Contact Resistance

- 3. Check Insulation Resistance (IR) Across Poles

- Preventive Maintenance Activity Checklist

- 1. Obtain PTW & Ensure Proper Isolation

- 2. External Breaker Inspection

- 3. Turn Off DC Supply & Remove Control Plug

- 4. Discharge Closing & Tripping Springs

- 5. Clean Breaker, Insulators, & Breaker Chamber

- 6. Observe Oil Leakage (MOCBs)

- 7. Lubricate Moving & Sliding Parts

- 8. Ensure Earthing of Outgoing Cables

- 9. Inspect Cable Terminations & Surge Arresters

- 10. Verify Smooth Racking Mechanism Operation

- 11. Check Indication Lamps

- 12. Test Space Heaters

- 13. Check Contact Erosion

- 14. Measure Breaker Timings

- 15. Check Oil Condition in MOCBs

- 16. Evaluate vacuum interrupters (VCBs)

- 17. Determine Contact Resistance

- 18. Inspect Mechanical Interlocks

- 19. Remove Earthing & Secure Doors

- 20. Rack in Breaker in Tripped Condition

- 21. Insert Control Plug & Restore DC Supply

- 22. Test Breaker in Test Position

- 23. Conduct Relay Tripping Tests

- 24. Return PTW

- Authorization

- Checklist

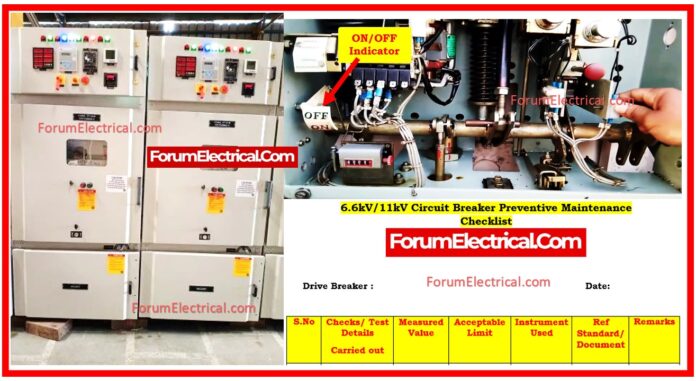

Regular preventive maintenance of 6.6kV & 11kV circuit breakers ensures that power distribution systems run smoothly, reduces downtime, and avoids future breakdowns.

The checklist below is divided into two sections:

- Circuit Breaker Testing Checklist

- Preventive Maintenance Activity Checklist

Test-based performance evaluation & step-by-step physical maintenance activity, both of which are required to preserve operational integrity.

Circuit Breaker Testing Checklist

This section describes the standard testing techniques that must be followed during preventative maintenance.

Each test verifies several aspects of the breaker’s health, including mechanical performance, insulation, and contact integrity.

1. Check Breaker Timings

A circuit breaker analyzer kit is used to test the timing of breaker operations. This tests the opening, shutting, & bouncing times of contacts to ensure mechanical parts are operating within acceptable parameters.

Prolonged timings could indicate mechanical wear (or) lubrication concerns.

2. Check Contact Resistance

The main contacts’ resistance is tested with a micro-ohm meter.

High contact resistance may indicate contact erosion or oxidation, which can cause heating & inefficiency during operation.

The value must fall within the manufacturer’s specified range.

3. Check Insulation Resistance (IR) Across Poles

Use a 5kV or 1kV megger to measure insulation resistance (IR) across breaker poles.

This is essential for detecting degeneration in insulation material, which can lead to internal failures or flashover.

Minimum acceptable values must be based on ISO/IEC standards (or) OEM guidelines.

Preventive Maintenance Activity Checklist

This section discusses physical inspection, cleaning, mechanical tests, and functional verification methods to ensure the circuit breaker is in good working order.

1. Obtain PTW & Ensure Proper Isolation

Begin by obtaining a Permit to Work (PTW) & establishing full electrical isolation.

When working with medium-voltage switchgear, safety is the most important consideration.

2. External Breaker Inspection

Visually inspect the breaker for signs of physical deterioration, rusting, or contamination.

This includes inspecting the

- Panel’s surface,

- Nameplates,

- Wire quality, and

- Signs.

3. Turn Off DC Supply & Remove Control Plug

Turn off the DC power source to prevent unwanted actions.

Before proceeding with any internal work, remove the control plug to completely isolate the control circuit.

4. Discharge Closing & Tripping Springs

If the breaker is spring-operated, make sure the springs are drained before performing any maintenance.

This prevents unintended movements when service.

5. Clean Breaker, Insulators, & Breaker Chamber

Dust, carbon deposits, and foreign particles can be removed from inside surfaces using a dry cloth or a vacuum cleaner.

Clean the insulators to prevent tracking and flashover.

6. Observe Oil Leakage (MOCBs)

Check for oil leaks in Minimum Oil Circuit Breakers (MOCBs). Leaking oil can weaken insulation and cause fires.

Before proceeding with additional testing, stop any leaks that have occurred.

7. Lubricate Moving & Sliding Parts

To ensure that sliding surfaces, interlocks, racking mechanisms, & latch parts operate smoothly, use the proper grease or lubrication.

8. Ensure Earthing of Outgoing Cables

Check that the outgoing cable ends are correctly earthed before handling terminals.

This is an precautionary measure to avoid residual charge shocks.

9. Inspect Cable Terminations & Surge Arresters

Look for evidence of

- Overheating,

- Discolouration, or

- Loose connections

at the terminal lugs.

Also, check surge arrestors for cracks, wear, and missing pieces.

10. Verify Smooth Racking Mechanism Operation

Ensure that the breaker racks move smoothly into & out of the cubicle with minimal resistance.

Lubrication & alignment may be required if binding is detected.

11. Check Indication Lamps

Check that all panel indication bulbs (Trip, Close, Healthy, etc.) are working. Replace faulty bulbs (or) LEDs as necessary.

12. Test Space Heaters

Space heaters keep moisture from condensing inside the breaker panel. Test their resistance and functionality.

13. Check Contact Erosion

Examine all primary contacts for evidence of pitting, wear, and discolouration.

If the erosion exceeds the permitted limit set by the manufacturer, replace the contacts.

14. Measure Breaker Timings

Repeat breaker timing tests after maintenance to confirm improvements or consistency in operation.

15. Check Oil Condition in MOCBs

Assess oil condition in MOCBs by sampling and testing for dielectric strength, moisture content, and sludge presence.

If the oil does not satisfy the dielectric specifications, replace it.

16. Evaluate vacuum interrupters (VCBs)

For vacuum circuit breakers, examine the insulating resistance of the vacuum bottle.

A decline in IR value may indicate internal arcing or a loss of vacuum integrity.

17. Determine Contact Resistance

Verify contact resistance after cleaning and tightening. Low resistance minimizes energy loss & heating.

18. Inspect Mechanical Interlocks

Check the mechanical & electrical interlocks that govern the close/trip actions. To avoid misoperation, all interlocks must function properly.

19. Remove Earthing & Secure Doors

After conducting internal checks, disconnect temporary earth connections & securely close & lock all compartment doors.

20. Rack in Breaker in Tripped Condition

To avoid unintentional energization, ensure that the breaker is only racked into the service position when triggered.

21. Insert Control Plug & Restore DC Supply

Reconnect the control socket and turn on the DC supply to ensure the control circuit is completely operational.

22. Test Breaker in Test Position

Switch the breaker to the test position to ensure adequate control response without igniting the load.

23. Conduct Relay Tripping Tests

To check that the breaker trips successfully on a protection instruction, simulate problems using relay circuits.

24. Return PTW

Return the PTW – permit to work and notify the appropriate staff once all maintenance tasks have been completed and the system has been verified safe.

Authorization

All works must be signed by both the Site Engineer & the Maintenance Engineer. This assures accountability and adherence to safety & operational standards.