- What is the Basic Electrical Maintenance?

- What is Preventive Maintenance in Electrical?

- Why Should Electrical Systems Undergo Preventive Maintenance?

- 10 Reasons for Conducting Electrical Preventive Maintenance

- How Frequently Should Electrical PM be performed?

- Sample PM Tasks for Electrical Systems

- Checklists and Resources for Electrical Inspections

- General Annual Checks

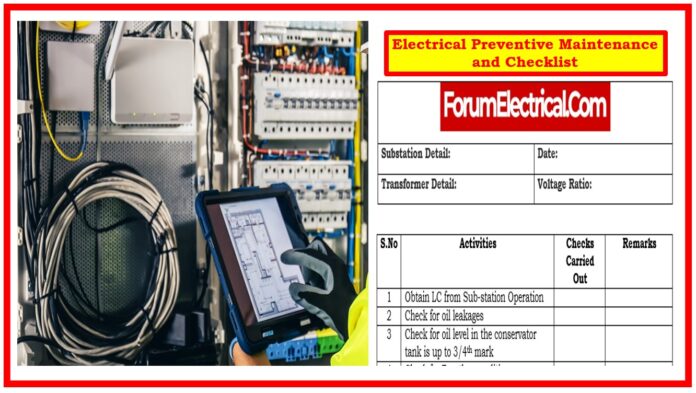

- Sample Checklist

- 1). Switch Board Maintenance Checklist

- 2). Transformer Maintenance Checklist

What is the Basic Electrical Maintenance?

Electrical maintenance is a method of ensuring that electrical equipment remains in perfect working condition. It involves checking, testing, & repairing electrical equipment as needed to avoid faults that could result in a loss of power (or) an electrical fire.

What is Preventive Maintenance in Electrical?

The term “electrical preventive maintenance” (EPM) refers to a program of frequent inspection and servicing of equipment in order to detect possible faults and take appropriate corrective action using approved work process controls.

Why Should Electrical Systems Undergo Preventive Maintenance?

Many industries have higher power requirements in the winter and summer because facilities find it difficult to keep structures warm and their assets running. In addition, facility as well as plant managers struggle in the current economic climate to reduce power consumption in order to save expenses.

10 Reasons for Conducting Electrical Preventive Maintenance

- Avoid Electrical Shorts which lead to Fires: Electrical short circuits may happen when cables are overloaded with current, wires are exposed, or there is a load imbalance. This can result in excessive heat buildup, arcing, or explosions.

- Identify Loose Connections: Loose connections may lead to power fluctuations, inconsistent device operation, and uneven load distribution across cables.

- Overheat Issue: Determine whether components are running hot or not according to specs. Transformers, motors, bearings, and cables almost usually overheat before they fail. Predictive maintenance technology like infrared thermography, vibration analysis, and laser alignment tools, as well as standard maintenance like regular lubrication, can help prevent asset failure.

- Identify any strange Odors, Noises, Dust Accumulation, or Discoloration: Melting insulation, strained motors, corrosion caused by dust, and other factors necessitate physical inspection of electrical components. Electrical troubleshooting and simulation should be done in a methodical manner.

- Inspect all Emergency Lighting, Signage, and Power Indicator Displays: Many electrical accidents occur if the safety monitoring equipment itself fails, leading to the incorrect perception that everything is well.

- Increase the usable lifetime of Assets: Poorly maintained assets consume more energy to perform the same amount of labor. This results in severe wear & tear & a shortening of the asset’s useful life.

- Avoid Unforeseen Downtime: Unexpected downtime can cause production to stop, incurring emergency labor expenses and requiring costly capital asset replacement. Without sufficient electrical training, all of these have a substantial influence on the organization’s profitability.

- Less Equipment Loss: Consistent electrical preventative maintenance will limit the number of components that need to be replaced prematurely due to electrical issues.

- Energy Savings: Optimal energy efficiency is achieved when equipment operates within design limitations and is adequately maintained.

- Safety & Liability: The most essential consideration is safety. Preventing serious injuries (or) death is well worth the money paid. Liability lawyers have a field day if facilities have an inadequate maintenance history.

How Frequently Should Electrical PM be performed?

Electrical systems should be thoroughly inspected by an experienced electrician. The frequency can be quarterly, semi-annually, annually, biannually, and so on. It is dependent on the servicing of the equipment, and the decision should be made by the section head.

Individual resources must be inspected in accordance with manufacturer instructions, or based on expertise & industrial training in a specific setting.

Ex: Some motors may require quarterly inspections, air handlers annually, and so on.

Preventive maintenance, inspections, and work orders are best managed with your own excel sheet or specialized software for scheduling and documenting activities, results, and remarks.

Preventive maintenance for electrical systems extends beyond visible or scheduled predictive maintenance. A full electrical PM is an in-depth examination at the electrical system.

Sample PM Tasks for Electrical Systems

- Adherence to safety audit recommendations

- Tighten connections carefully

- Examining panel boards

- Checking the efficiency of control logic, schemes, and PLCs

- Checking new installs and work orders for uniformity and compliance

- Verifying the presence of lock-out tags

- Heating & cooling unit inspection

- Lighting

- Shutdown procedures

- Compliance with NEC codes

Checklists and Resources for Electrical Inspections

Every company has a distinct set of resources. Consequently, it is improbable that the electrical inspection checklist will be identical.

The manufacturer typically gives a maintenance checklist, which should be followed, or we can create our own with our own practice.

General Annual Checks

- Analyze previous maintenance records to identify repair patterns. These records may identify specific components that require close inspection during preventative maintenance.

- Check operator records for electrical load readings and compare them to equipment ratings. Operator records for operating temperatures, as well as any reported anomalous conditions involving the system, should be checked.

- Inspect the Secondary Electrical Distribution Equipment:

- Check to ensure that warning indicators are present. Replace as needed.

- Examine enclosures for damage, unauthorized openings, & corrosion of metal objects. Repair & paint as needed.

- Inspect the air passageways and clear any blockages.

- Inspect, investigate, & resolve issues involving odd scents.

- Listen for unexpected noises while operating and testing equipment. Look into and fix the problem.

- Check electrical connections for wear and tightness. Repair as needed.

- Check electrical insulation for discoloration and degradation. Repair as needed.

- Examine the equipment grounding components, such as conductors and connectors. Repair as needed.

- Inspect the insulators for damage. Replace as needed.

- Inspect liquid-immersed equipment for leaks & damage.

- Check the indication lights for proper illumination.

- Remove any debris, dirt, or foreign items from every component, housings, cabinets, & panels.

- Torque every electrical connection to the design value.

- Check the functionality of the space heaters & control thermostat.

- Check the thermostat set point to ensure it is properly set.

- Check the equipment’s grounding and any associated neutrals.

- Conduct an infrared test on all main current-carrying equipment for hot patches that could indicate overload or loose connections.

- Use calibrated test tools to calibrate ammeters, voltmeters, and so forth. Use an ohmmeter to verify the continuity of the metering selector switch connections.