- Transformer Ratio Test

- Transformer Ratio Test and Phase Displacement Measurement

- How to Conduct the Transformer Turns Ratio Test?

- 5 Step Procedure to Test Transformer Turns Ratio

- Step 1: Taking the Necessary Precautions to Ensure Safety

- Step 2: Establishing Connections

- Step 3: Calibration

- Step 4: Initiation of the Tests

- Step 5: Measurement & Calculation

- Importance of the Transformer Turns Ratio Test

- How do you test Transformer Turn Ratio?

- Why is TTR Test important?

- Relevant Codes & Standards

Transformer Ratio Test

The efficiency of a transformer is mostly determined by the perfection of certain turns or the transformer’s voltage ratio.

As a result, transformer ratio testing is an important type of transformer test. To avoid dangerous voltage, just apply the voltage to the high voltage winding.

Transformer Ratio Test and Phase Displacement Measurement

Actually, the transformer’s no-load voltage ratio equals its turn ratio. So this is a transformer ratio test.

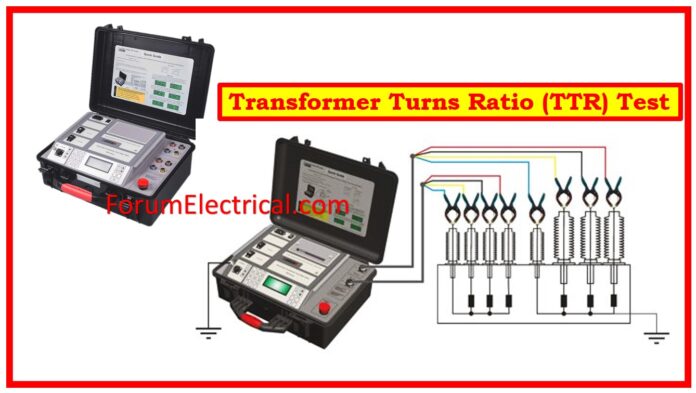

How to Conduct the Transformer Turns Ratio Test?

Depending on your preferences, you can determine the turns ratio using a turns ratio meter (or) a transformer turns ratio test kit.

5 Step Procedure to Test Transformer Turns Ratio

The following is an overview of the procedure that should be followed to conduct the test:

Step 1: Taking the Necessary Precautions to Ensure Safety

Before you conduct any kind of test, you need to be sure that the transformer has been de-energized & disconnected from its connection to the power supply.

It is important to take the proper precautions, such as grounding and wearing protective clothes, in order to lessen the possibility of getting involved in an accident.

Step 2: Establishing Connections

Make sure that the transformer is correctly linked by creating the necessary connections. This will make sure that the turns ratio test set is functioning effectively. Additionally, the secondary winding is typically connected to the low-voltage side of the test set, whereas the primary winding is typically connected to the high-voltage half of the test set.

Step 3: Calibration

In order to ensure that the measurements you obtain are accurate, you need to initially calibrate the turns ratio test set in compliance with the instructions that were provided by the manufacturing company.

Step 4: Initiation of the Tests

In the first part of the test, an alternating current voltage is applied to the main winding.

This is done after checking that the connections are properly positioned and well-secured.

The equipment being tested is going to take a measurement of the voltage that is produced in the second winding at this point in time.

Step 5: Measurement & Calculation

On the test set, the turns ratio that was calculated will be displayed. In order to ascertain the condition of the transformer, it is necessary to compare this value to the construction standard.

The results of the test may also disclose the presence of potential issues, which include

- Short circuits in the windings,

- Open windings, or

- Winding shifts.

Importance of the Transformer Turns Ratio Test

The transformer turns ratio test is an important diagnostic & quality assurance process used in transformer maintenance and manufacture.

- Quality Assurance: Quality assurance involves testing the turns ratio to ensure that the transformer is constructed in accordance with the design parameters. Any variation from the stated turns ratio may indicate manufacturing faults (or) errors, such as faulty winding or shorted turns.

- Performance Verification: The turns ratio has a direct impact on the transformer’s performance, including the voltage transformation ratio & impedance matching capabilities. Engineers can confirm that the transformer will function properly within the specified voltage and current limits by testing the turns ratio.

- Fault Detection: Differences in the turns ratio can indicate a variety of defects in the transformer, including shorted turns, open windings, and turn insulation breakdown. Detecting these defects early through turns ratio testing may assist to prevent further transformer damage and costly downtime.

- Efficiency Assessment: The turns ratio test can provide information about the transformer’s efficiency. Deviations from the desired turns ratio may result in increased losses and lower efficiency, indicating the need for maintenance (or) replacement.

- Safety Assurance: Maintaining the proper turns ratio is important for safe operation circumstances. Incorrect ratios can cause over voltages (or) under voltages, creating a risk to connected equipment & persons.

- Preventive Maintenance: Preventive maintenance for transformers includes periodic turns ratio testing. Maintenance teams can avoid costly failures by checking the turns ratio on a regular basis.

- Regulatory Compliance: Many businesses require transformer testing and maintenance to assure safety, reliability, & compliance. Turns ratio testing is frequently a mandatory operation to meet regulatory standards.

Overall, the transformer turns ratio test is critical to ensure transformer dependability, safety, and performance in a variety of applications, including power distribution, industrial processes, & electrical infrastructure.

How do you test Transformer Turn Ratio?

In general, the TTR test is carried out by turning on the transformer’s high voltage (HV) winding & measuring the voltage on the low voltage (LV) winding. This is also known as the step-down method of testing. The test voltage utilized to generate the winding can influence the measurements.

Why is TTR Test important?

TTR testing is a valuable tool for analyzing the quality of a transformer’s windings, core, and insulation. The test is simple, but several factors, including

- Core permeability,

- Leakage flux,

- Excitation losses, and

- Winding configuration,

might influence the accuracy of the results.

Relevant Codes & Standards

IEC 60076-3: “Power transformers – Part 3: Insulation levels, dielectric tests and external clearances in air,” specifies power transformer insulation, dielectric testing, and external clearances. Section 3 measures winding resistance, turns ratio, and polarity.

IEEE C57.12.90: The “IEEE Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers,” describes how to test liquid-immersed transformers, including turns ratio tests. It covers test methodologies, equipment setup, and acceptance criteria.

ANSI/IEEE C57.12.70: “IEEE Standard Test Code for Dry-Type Distribution and Power Transformers,” covers dry-type distribution and power transformer testing. Turns ratio testing is used to measure transformer impedance and voltage ratio in Section 6.