DC motors can be said to be more commonly used than the other types of motors and this is because DC motors are normally used in industries and commerce since they are easily controlled, very reliable and are efficient.

Starter in DC Motor

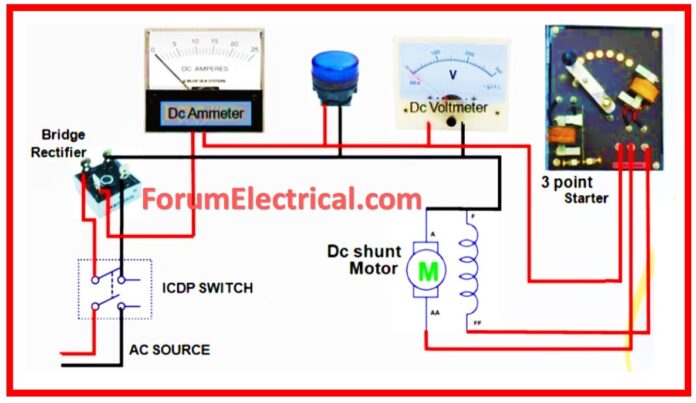

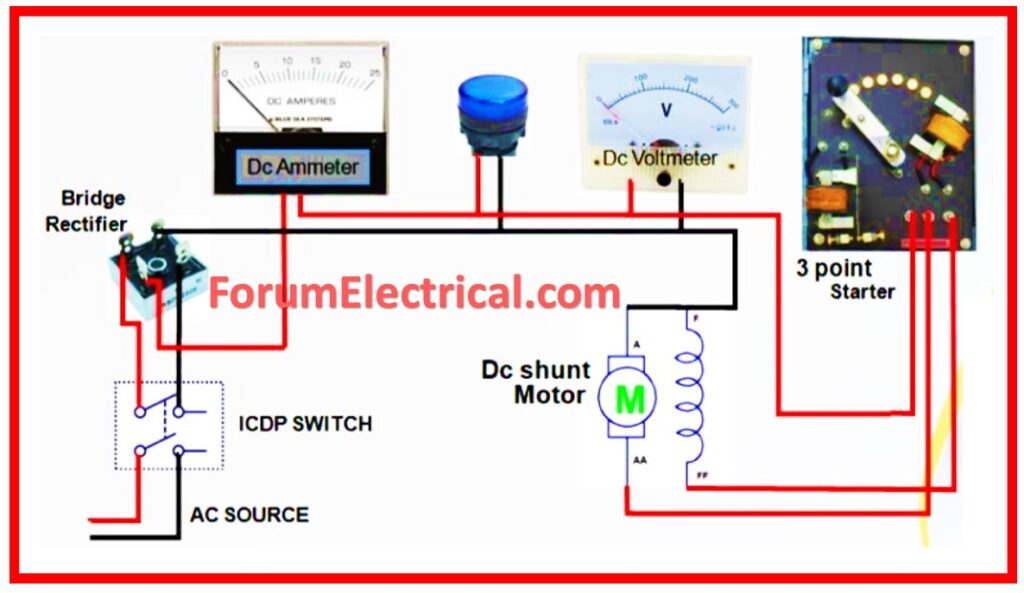

In a DC motor, a starter is necessary because it regulates the current at starting time, permits smooth and automatic acceleration of a motor, protects a motor and circuit against damage, and improves energy efficiency.

However, failure to use a starter when starting a DC motor has some operational challenges and possible damages as mentioned below.

In this post, we explain the basic indispensability of starters in DC motors with regard to functions and protection.

Necessity for Starters in DC Motor

The reason why there is a necessity of starter in a DC motor are as follows The primary necessity of a starter in a DC motor arises from the reality that a motor has to be started on no load or on a very light load as otherwise due to the presence of armature reaction the field poles, become demagnetized and there will be insufficient torque to keep the motor running for the required load.

Some of the uses of starter in DC motor includes:

1). Inrush Current Control

2). Controlled Acceleration

3). Motion Protection

4). Remote Control and Automaton

5). Energy Efficiency

6). Motor Mechanical Stress Protection

7). Overload Protection

8). Application-Specific Customization

1). Inrush Current Control

Inrush current control refers to the initial large current that passes through a circuit during the initial period of circuit turn-on.

The high inrush current that occurs when the motor has been initially switched on is another critical factor that benefits from the incorporation of a starter with discrete motor specifications such as the DC motor.

Starting current of a DC motor is several times its full load current, this is because at starting the motor consumes the maximum current it is capable of taking from supply.

This occurs because of:

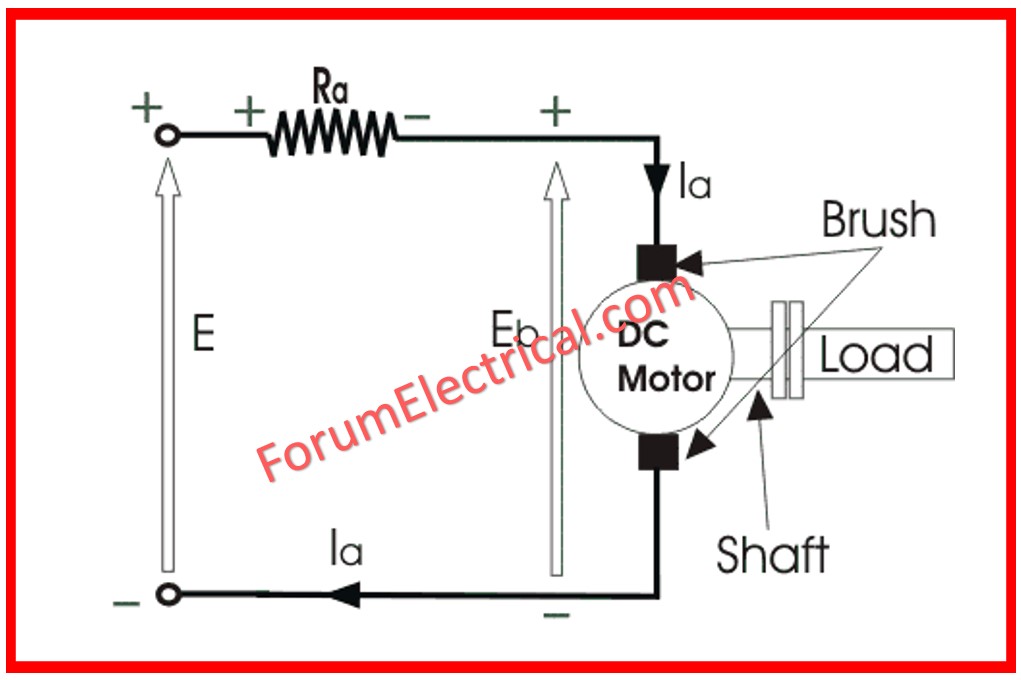

Low Armature Resistance: At the startup, the resistance of the armature can be regarded as almost zero; therefore, there is an increase in current. This is because resistance in a circuit increases with temperature and since running the motor causes an increase in temperature of the motor, then the resistance increases.

Absence of Back EMF: The motor has not started to produce back electromotive force (EMF); this usually is in opposition to the supply voltage and restricts current flow. The back EMF depends on the speed of the motor and is zero when the motor is stationary.

According to dielectric potential and mathematically the armature current is given by the following equation:

Ia = V – Eb/Ra

While Starting,

N = 0

Eb = 0

Ia = V/Ra

Ia (at start) >> Ia (run)

The above equation clearly depicted that the starting current of the DC motor is high. To restrict the starting high current, the resistance is inserted in the series with the armature to reduce the starting current.

This high inrush current can cause several issues:

- Electrical Stress: In the event of high current heating is inevitable and may culminate into damage of the motor windings.

- Power Supply Fluctuations: A high initial current also slams the power supply network affecting other devices that are connected simultaneously to the network.

- Torque Variations: The unexpected torque might mechanically stress the motor and related components.

By progressively increasing the current provided to the motor, starters limit the inrush current and ensure a smoother startup, therefore lowering the danger of damage.

2). Controlled Acceleration

Starting a DC motor directly can cause fast acceleration, which would not be desired for a number of reasons.

- Sudden acceleration can produce mechanical shock to the motor & the load it drives, therefore causing wear and tear (or) mechanical failure.

- In machinery, swiftly, uncontrolled acceleration can seriously endanger operators and surrounding workers.

- By progressively raising the voltage (or) current sent to the motor, starters enable regulated acceleration.

This regulated ramp-up guarantees the motor reaches its running speed gradually, therefore reducing mechanical strain and improving safety.

3). Motion Protection

Many times, motor starters include several protection elements meant to protect the motor during both startup & normal running:

- Starters help to identify and restrict too much current, so reducing overheating and possible damage.

- Starting can disconnect the motor to stop harm from under-voltage conditions should the supply voltage drop below a crucial threshold.

- Many starters have thermal overload protection that disconnects the motor should it overheat.

Particularly in severe industrial settings, these protective systems are absolutely essential for preserving the dependability and lifetime of the motor.

4). Remote Control and Automaton

In many industrial uses, motors are started & stopped regularly under occasionally different conditions. Each operation can have unrealistic and ineffective manual control.

Starters assist:

- Starters can be set to start & stop motors depending on preset criteria such time periods, temperature, or load requirements.

- Modern starters sometimes let for remote control, thereby enabling motor activation from a central control system (or) a distance.

This automation & remote control capacity increases general process control, lowers the need for human intervention, and increases operational efficiency.

5). Energy Efficiency

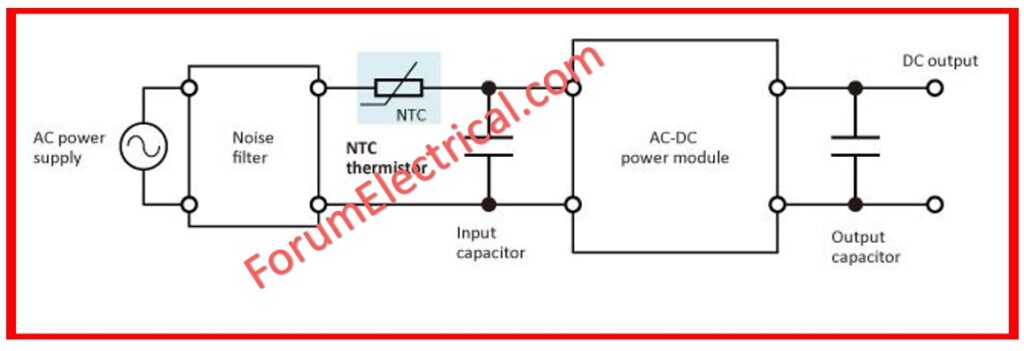

Designed to maximize energy use, modern electronic starters include thyristor drives for starting & speed control of the DC motor.

These starters make sure that the motor runs at maximum efficiency by accurate control of the voltage & current provided to it.

This reduces running costs and environmental effects as well as energy usage.

6). Motor Mechanical Stress Protection

Full voltage applied suddenly to a DC motor can cause an immediate acceleration that stresses the motor components & associated machinery.

This stress could cause too much wear and tear, therefore reducing the service life of the motor.

Starters allow the motor to ramp up smoothly by progressively raising the voltage, therefore lowering mechanical stress.

7). Overload Protection

Many times, starters have overload protection mechanisms that shield the motor from running for extended durations at too high currents. This precaution helps stop possible motor windings damage and overheating.

8). Application-Specific Customization

Manual, magnetic, & electronic starters among other types have features specialized to particular uses.

Electronic starters, for instance, fit complicated and exact uses since they can offer programmable settings for the acceleration, deceleration, & torque control.

Starters are therefore highly important in DC motor systems for mechanical and electrical component protection, assuring smooth operation, and necessary control characteristics. Their importance is significant in improving the dependability, efficiency, & safety of the DC motor-driven systems.