What is an RCD?

RCD – Residual Current Device

A Residual Current Device (RCD) is a type of electrical protection equipment that acts to disconnect a circuit in the case of a fault.

- What is an RCD?

- How are RCDs tested?

- What happens during RCD Testing?

- Why Residual Current Device Testing carried out?

- How frequently must RCD testing occur?

- RCD Testing Procedure

- Preparation

- Visual Inspection

- RCD Tester Test

- Operating Time Test

- Trip Time Test

- Push-button Test for RCDs

- Portable RCD Test

- Verification

- Certification

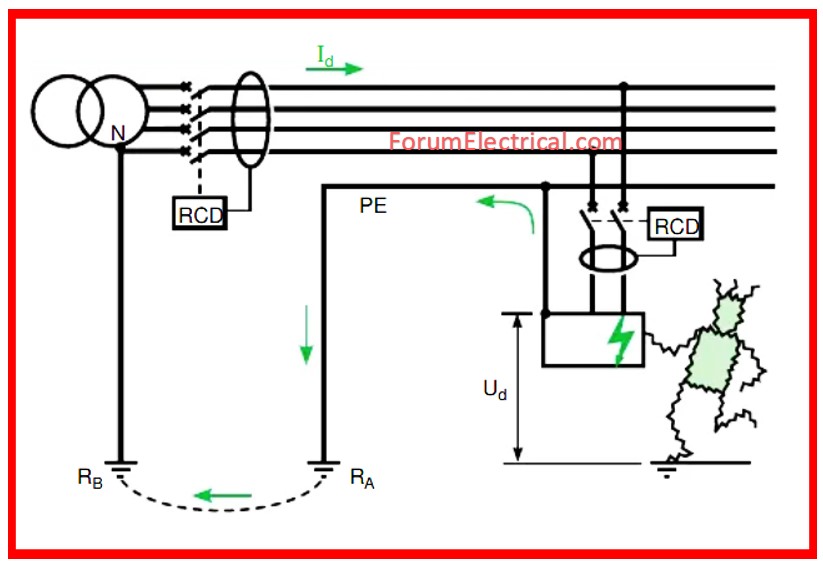

Residual Current Devices (RCD) are intended to defend against the hazards of electrocution and fire generated by earth faults.

RCDs are extremely sensitive and will trigger within 10 to 30 milliseconds, blocking the flow of power.

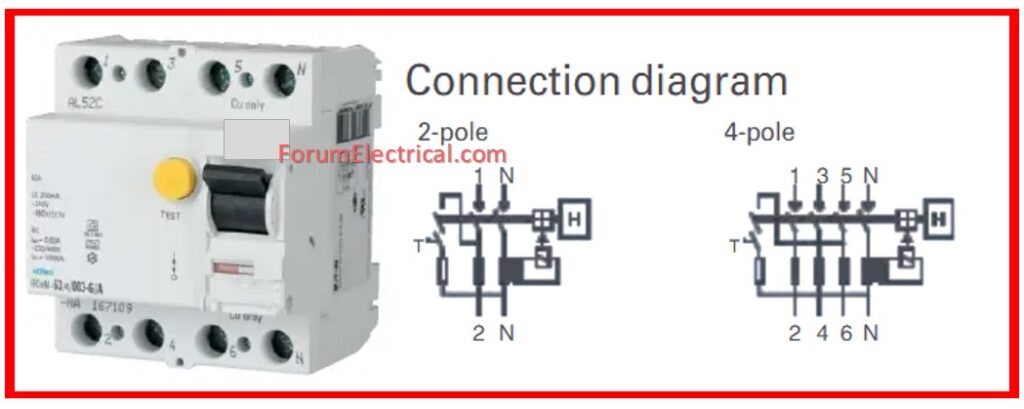

Continually monitoring the proper balance of currents across the Line conductor & the Neutral conductor is the working principle behind the Residual Current Device, which functions on this basis.

In case this balance is disturbed, it indicates that the current flowing from the line conductor is being directed to a different location than the neutral conductor, specifically to earth, as a result of a malfunction that occurs somewhere within the arrangement.

One of the standard home RCDs has a maximum of 30 milliamperes (30 mA).

The human body is able to resist a current of that amount, which is the reason why this is applicable.

Anything that was higher than this would be hazardous to one’s life, which is why the RCD would cut off the supply of it.

How are RCDs tested?

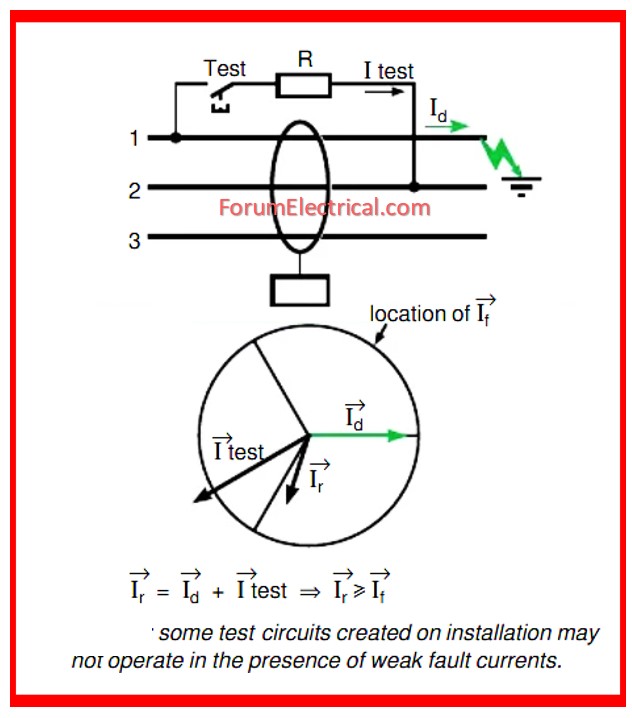

In order to comply with the wiring standards, the residual device that provides additional protection should disconnect within thirty milliseconds (30 ms) if it is tested at five times the typical current that it needs.

This is done by electricians using calibrated equipment, not individuals. It is one of the electrical inspection tests that determines if the RCD will disconnect in time to prevent shock.

Other testing show the device(s) are not over-sensitive and would not drain power. Before RCD testing, turn off any electrical equipment because it will trip RCD & disconnect the circuit it protects.

RCD tests take about 5 minutes separately. RCD Testing should be done after working hours, or be prepared to inform staff of power disruptions and computer shutdowns for each circuit.

What happens during RCD Testing?

- If a 30mA RCD provides additional protection, the operation period should not exceed 30 ms at 5 A residual current

- On load side of RCD, the protected circuit phase conductor and cpc are tested.

- Disconnect loads and appliances before testing.

- The phase & neutral of the circuit under test supply a few milliamperes for RCD test devices.

- A three-phase RCD protecting a 3-wire circuit must have its neutral connected to earth when tested.

- The instrument supply current shall increase the test current, causing some devices to function during 50% test, possibly suggesting an improper operation duration.

- Before failing the RCD, confirm its operational specifications with the manufacturer.

- The RCD testing needs to be carried out in all devices every three months.

- If the test fails, the management needs to obtain a new device & turn off the power. They must tag & lock (LOTO) the device where it is utilized.

- This alerts workers to a problem and disables their connections.

Why Residual Current Device Testing carried out?

Electrical materials and aged wiring can have minor ground leakage that trips an RCD.

Earth leakage rises with each electrical item plugged in, & if RCD keeps triggering, circuit overload may be the cause.

If an RCD keeps tripping, have an electrician inspect your wiring and appliances.

Professionally fitted and tested RCDs could have avoided most electrical injuries.

Appliance, tool, and electrical problems can cause fires, but RCDs prevent them.

Undiscovered defects could cause fires or injuries. RCDs identify faults early.

Thermal Scanners does all RCD Testing and provides a comprehensive report & compliance certificate.

An RCD can save lives and prevent appliance or wiring fires if properly maintained.

Thermal scanners assist clients test and comply with Standards for RCDs.

How frequently must RCD testing occur?

An electrician must retest, fix, or replace the switch if the power fails to turn off. For safety, all homeowners – even those not selling – should install the devices.

Implementing residual current devices is cheap compared to family safety.

Follow the test intervals in section over to comply with the specification.

RCD Testing Procedure

Preparation

Before testing, turn off all electrical devices connected to the RCD to avoid interference with test results.

Visual Inspection

It is important to visually inspect RCD and the areas surrounding it for any signs of damage, wear, (or) modifications.

Make sure it is correctly mounted and clear of impediments.

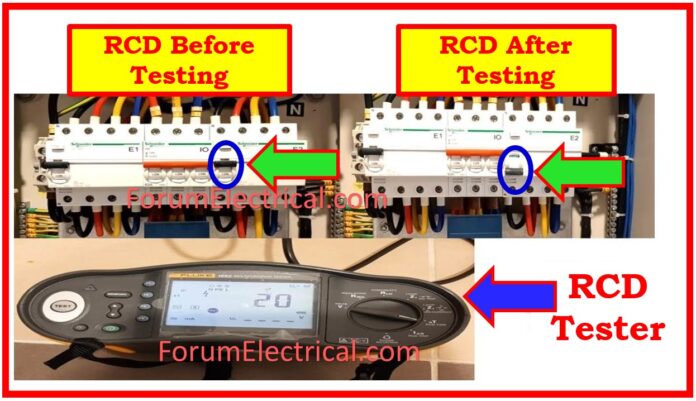

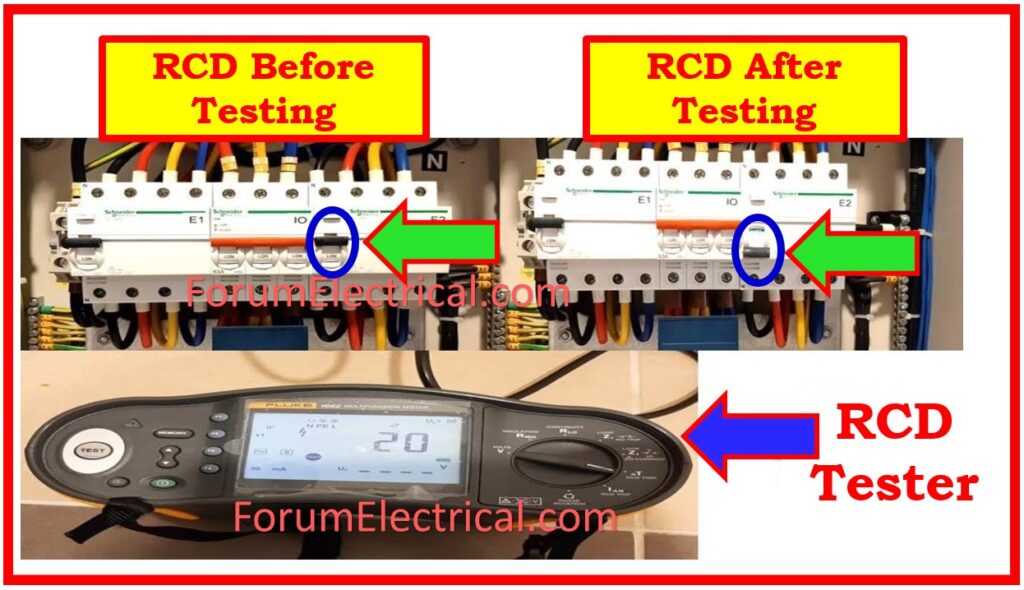

RCD Tester Test

A residual current device tester is required if you wish to perform more than the basic test. A more comprehensive analysis of the RCDs can be obtained with this specific unit of equipment.

Although RCD testers are available for purchase, experienced electricians are typically the only ones who utilize them. We advise you to have your RCDs tested by an expert if you are uncomfortable utilizing one.

When employing an RCD testing equipment, there are two distinct tests:

- Operational Time Tests and

- Trip Time Tests.

These are the two RCD testing techniques, briefly discussed.

Operating Time Test

An electrician performs this test, which monitors how long it takes the RCD to trip, signaling whether it is sufficiently quick to be effective.

Trip Time Test

It measures the real trip time and must be done with equipment that can measure it to within +/- 8 ms (0.008 second).This is a simple test that the user can do to ensure that the RCD’s tripping mechanism works.

RCD maximum trip time Chart as per different standard

RCD Maximum Trip Time Chart | |||

| Test current | BS 4293 | BS EN 61008 | BS EN 61009 |

| 50 % In< | No trip | No trip | No trip |

| 100 % In | 200 ms | 300 ms | 300 ms |

| 500 % In | 40 ms | 40 ms | 40 ms |

Push-button Test for RCDs

This test should be done daily (or) before each time we use the RCD, whichever is longer. However, it is not accurate and cannot be depended on as an accurate evaluation of the RCD’s functionality.

AS/NZS 3760 mandates the “trip time” test for RCDs, which uses the “applied current” method for greater accuracy.

Portable RCD Test

To perform an operational time test on portable RCDs, an isolation transformer is required.

Follow these simple procedures to confirm that your RCDs are working properly.

Step-1: Plug a lightbulb into a power outlet and ensure that it works. Keep it turned on.

Step-2: Ensure electrical power is connected to the house & the main switch is turned “on”. The lamp should be turned on.

Step-3: Turn off all electrical devices (computers, TVs, etc.).

Step-6: Check that all of the lights & power points are not working.

Step-7: To accomplish this, plug small bulb into each power outlet and turn the power on. If the lamp turns on, a licensed electrician must be hired to repair the wiring.

Verification

After rectification, re-test RCD to ensure that it now meets the performance requirements.

Certification

When the RCD has successfully completed the testing procedure, a certificate or other paperwork verifying that it complies with legal safety regulations should be issued.