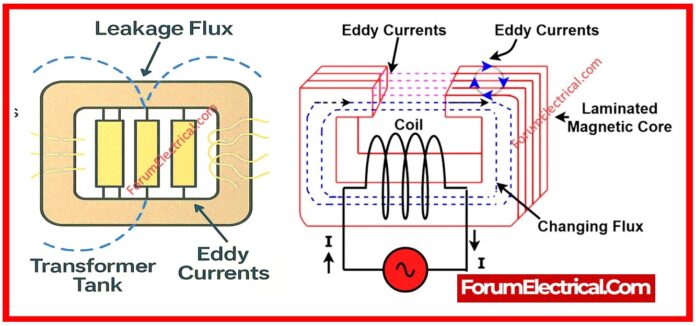

Stray losses in a transformer are caused by leakage fluxes (i.e., magnetic flux that is not contained within the core) that induce eddy currents in neighboring metallic parts which include the

- Transformer tank,

- Core clamps,

- Winding conductors,

- Structural sections, and so on.

These losses are alongside the typical core & copper losses.

Types of Transformer Losses

Core (Iron) Loss

Core (Iron) Losses include hysteresis & eddy current losses in the core.

Copper (Ohmic) Loss

Copper (Ohmic) losses occur due to I²R in windings.

Dielectric Loss

Dielectric Losses are insulation losses (with minimal power frequency).

Other Minor Losses: Brush contact, cooling system losses, etc.

Stray Loss

Stray Losses are induced eddy currents in the structural elements caused by leakage flux.

What is Stray Loss?

In a practical transformer, a portion of the total flux passes through air, which is known as leakage flux.

This leakage flux generates eddy currents in conducting or metallic elements, such as the transformer’s tank.

These eddy currents generate power loss, that is also known as stray loss.

We are all aware that a transformer operates on the concept of mutual induction, in which the alternating current in primary winding generates magnetic flux lines, which induce emf in the secondary winding.

However, in real time, not all of the flux created by the primary side is fully integrated with the secondary side. This is known as flux leakage, and it causes losses in the transformer, limiting output power.

This form of loss is referred to as flux (or) stray loss.

The primary & secondary windings of transformer should be wound in such a way that flux coupling between the coils is maximized.

In this manner, we may ensure maximum power transmission from primary to the secondary during flux connections, reducing flux losses.

What are the causes of Stray Losses?

When current flows via a transformer winding, it produces leakage magnetic flux, which does not follow the intended magnetic path in the core.

This stray flux flows via neighboring conductive objects, including:

- Tank walls

- Clamps and Bolts

- Core frames

- Windings (a non-uniform distribution)

These conductive materials respond to time-varying magnetic field by producing eddy currents inside themselves.

Eddy currents dissipate electricity as heat, which contributes to stray losses.

Components Affected by Stray Losses

| Component | Effect of Stray Losses |

| Tank walls | Localized heating & metal fatigue |

| Windings (specifically LV) | Uneven current distribution |

| Structural steel parts | Hot spots & possible loosening |

| Core yoke clamps | May need insulation (or) shielding |

Effect of Stray Losses

Stray losses typically make for 5% to 15% of a transformer’s total losses. They increase dramatically in:

- High current transformers (LV- Low Voltage side of the distribution transformers).

- Transformers with the compact designs (flux leaking near tank walls).

- Transformers without adequate insulation or magnetic balancing.

According to IEC 60076 & IEEE C57.12, stray losses should be included in total transformer losses.

Although they are not clearly stated, design documentation must indicate how stray losses were assessed and minimized.

How to Reduce Stray Losses?

Magnetic Shielding

Use non-magnetic barriers (or) shields across the windings & structural components.

Tank Design Modifications

To break up eddy current courses, use tank walls with slots (or) laminated surfaces.

Spacing

Increase the clearance across the windings and the tank/core clamps.

Applications of Magnetic Shunts

Redirect leakage flux away from the structural components.

Magnetic wall shunts help to reduce stray losses in power transformers by channeling leakage flux away from tank & structural components.

This eliminates eddy currents in the non-functional metallic components, reducing unnecessary heating and energy loss.

Magnetic wall shunts increase transformer efficiency and lifetime while also enhancing thermal management and lowering the possibility of hot spots.

Advanced Modeling

FEM (Finite Element Method) simulations are useful for forecasting and decreasing stray flux routes.

Calculation & Testing

Stray losses are not directly measured in standard tests.

They are usually calculated by subtracting observed no-load & load losses from overall losses.

Stray Loss Formula

Stray Loss = Total Load Loss – (Copper Loss at Test Current)

In special cases, unique stray loss testing is performed utilizing circulating current or short-circuit procedures.

Losses Comparison

| Type of Loss | Cause | Depends On | Load Dependency | Measurement & Test Method | Typical % of Total Loss | Impact |

| Core Loss (Iron Loss) | The alternating magnetic flux in core causes hysteresis and eddy currents. | Voltage, frequency, and core materials | Independent of the load | Open-circuit test (No-load test) | 20% – 40% | Continuous power loss, even with no load, decreases efficiency. |

| Copper Loss (I²R Loss) | Current flows through winding resistance. | Load current & winding resistance | Varies with the load (I²) | Short-circuit test (Load loss test) | 40% – 60% | Heat generation in the windings and insulation aging. |

| Stray Loss | Leakage flux causes eddy currents in surrounding metal parts. | Load current, design geometry & materials. | Varies with the load (I²) | Derived from load loss (copper loss) | 5% – 15% | Localized hot patches, structural tension, tank heating. |

| Dielectric Loss | Leakage current & polarization in insulating systems | Voltage, Insulation Quality, and Humidity | Independent of the load | Dielectric loss factor (tan δ), insulation tests | <1% | Insulation aging and corona discharge are essentially negligible. |

| Magnetization & Noise Loss | Physical distortion of core laminations due to magnetization | Magnetic Properties of Core | Independent of the load | Acoustic measurement, core design analysis | Negligible | Audible noise and moderate mechanical vibration. |

| Cooling & Auxiliary Loss | Power consumed by fans, pumps & control systems. | Cooling System Type | Varies slightly with the load | Measured separately during the factory tests | 1% – 3% | Reduces total net available output power. |

Summary

Stray losses, often neglected, affect transformer efficiency and thermal performance. Leakage magnetic flux interacting with the non-active metallic components causes localized heating and energy dissipation, unlike core or copper losses.

High-power (or) compact transformer designs require understanding their sources, consequences, and mitigation measures.

Magnetic shielding, improved shape, and advanced simulation can reduce these losses, improving transformer dependability, longevity, and energy efficiency.