Buchholz Relay

The Buchholz relay is used to protect the transformer against internal failures. It is the gas-actuated relay.

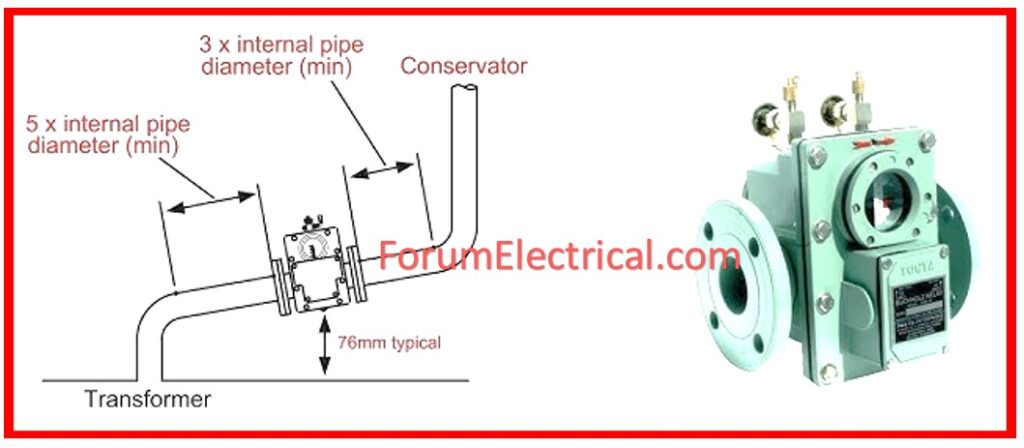

The Buchholz relay is located across the main tank & the conservator. This type of relay is utilized in transformers with ratings higher than 500KVA.

It is not utilized in tiny transformers due to economic reasons.

Working Principle of Buchholz Relay

When a fault develops inside transformer, the temperature of oil rises. The oil evaporates in form of gas.

The amount of gas produced depends on the severity of the failure that occurs inside transformer.

Internal failure in the transformer happens as a result of insulation breakdown among the windings (or) a weak initial contact.

The defect causes an arc, which raises the gas temperature. The oil evaporates and flows upward.

The Buchholz relay identifies the failure and sends an alarm to workers. The transformer is detached from the main power source for maintenance.

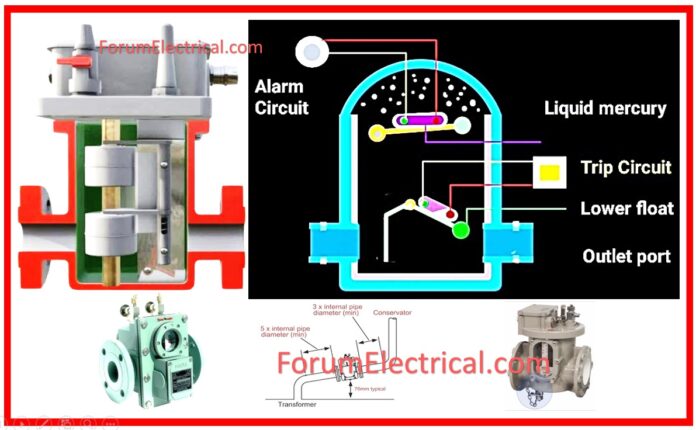

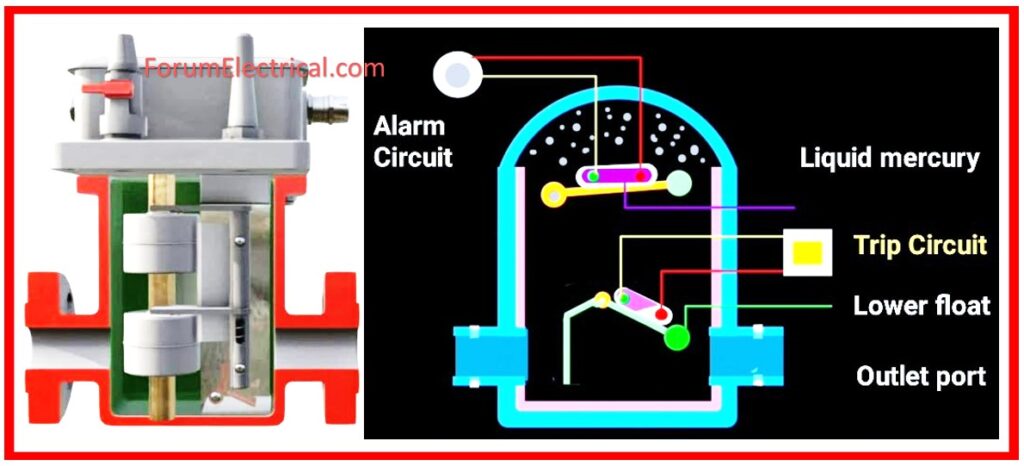

Construction of Buchholz Relay

The Buchholz relay has 2 hinges and is located in the metallic chamber.

The hose that connects the conservator to the main tank connects this metallic compartment.

One of the hinges is located in upper portion of metallic chamber, alongside the mercury switch.

This mercury switch is utilized to activate the alarm.

The other float and the mercury switch are located in the lower half of the metallic chamber.

The mercury switch is employed to activate the tripping circuit.

Function of Buchholz relay

Winding Fault

When an internal defect arises in the main tank due to a failure of the winding insulation (or) core heating, the oil temperature rises rapidly, and the oil begins to evaporate as a gas.

Gas moves upward and enters the relay, causing the gas float valve to move upward. For the alarm closing condition.

After closing the alarm, the supply breaker gets tripped.

Temperature Fault

The internal malfunction of the transformer causes the arc within the main tank. The thermal effect causes the transformer’s oil to heat up.

The gas rises, and only a small portion of its vapours gather in the upper part of main tank.

Evaporation causes the level of oil within the transformer tank to decrease.

The mercury switch inside metallic chamber tripped, and the relay alerted the staff.

The transformer’s supply runs low, so it is unplugged from the system for the purpose of maintenance.

The relay features a test cock that is used to release the pressure in the chamber.

When a significant fault develops inside transformer, the lower mercury switch in the metallic chamber tilts slightly, causing the tripping circuit to close.

Thus, transformer is detached from the main circuit.

The relay has a minimum operation time of 0.1 seconds.

Advantages of Buchholz Relay

- Buchholz relays detect internal defects caused by heating and aid in the prevention of catastrophic malfunctions.

- The severity of the defect can be determined without dismantling the transformer.

- If a large fault develops, the transformer may be isolated using a Buchholz relay to avoid accidents.

Disadvantages of Buchholz Relay

- The relay is exclusively used in oil-immersed transformers.

- It may only detect faults beneath the oil level.

- This relay doesn’t safeguard the connecting cables. As a result, each cable is protected separately.

- The relay has a high reaction time.

Why is Buchholz Relay used?

An oil transformer is a costly equipment.

- Overheating,

- Overload, (or)

- Short circuit in oil tank

can cause winding insulation to break or explode, resulting in the generation of gas that flows to the conservator side. To prevent winding and explosions in the tank, a Buchholz relay is set in the center of the tank and conservator.

When a defect occurs in a tank owing to high pressure gas, the buchholz relay activates and sends an alarm and tripping signal to transformer incomer breaker. Thus, the oil transformer may be blocked by a Buchholz relay.

Buchholz relay has 2 key aspects:

- If there is a failure in the transformer oil tank, it will generate an alert and a tripping signal to protect itself.

- If the oil level in the tank drops, it will sound an alarm and trigger a tripping signal for the protection.