What is a Cable Termination?

Cable termination is the method of attaching the end of a cable to a device like a switch or socket. This is done to ensure a reliable electrical connection.

- What is a Cable Termination?

- What is the most common cause of Failure in Cable Termination?

- Which Tool is used for Cable Termination?

- What is the Purpose of Cable Termination?

- Hazard Identification, Risk Evaluation, & Risk Control

- 1). Loop & Megger Check

- 2). Installation of Gland

- 3). Cable Termination

- 4). Completion of Cable Termination

- References

- Risk Assessment

- Conclusion

Cable terminations establish physical & electrical connections across the cable & the equipment’s terminal, junction, or another cable, allowing electricity to flow as needed.

Cables serve an important function in our environment. Everything that runs on electricity, including light bulbs, refrigerators, laptop computers, and automobiles, has cables. Our homes, offices, factories, villages, and cities all have wires, which provide electricity to operate the devices we use.

Cable terminations that meet international standards should have the following features:

- The cable joint kit (or) termination kits need to be simple and quick to install.

- They have already undergone durability and reliability tests.

- The cable terminations make sure the cables operate effectively, overhead, and even in the presence of water stagnation.

- Companies providing cable terminations provide the necessary service and assistance both during and after the sale.

What is the most common cause of Failure in Cable Termination?

Excessive heating of the cable will degrade the insulation & sheathing material, resulting in early failure.

Heat can come from an external source or be generated by the conductor’s resistance to current flow, which is especially problematic if the cable is overloaded (or) undervalued for the application.

Which Tool is used for Cable Termination?

Crimping is the most commonly used form of wire termination. It entails squeezing a connector upon the wire with a crimping tool to provide a secure & conductive connection.

What is the Purpose of Cable Termination?

Cable terminations are essential to the proper function of cables. Cable terminations provide physical & electrical connections across the cable & the equipment’s terminal, junction, or another cable, allowing electricity to flow as needed.

Hazard Identification, Risk Evaluation, & Risk Control

1). Loop & Megger Check

Electrocution is defined as accidental contact with active circuits, which results in severe harm or death.

Workers on the opposite end may accidentally come into contact with an electrified circuit.

Accident Possibility/Persons at Risk:

- Injury can result in lethal electrocution.

- All workers working close to the test area.

Existing Risk-Control Measures:

- Implement Lockout/Tagout (LOTO) protocols with warning labels shown.

- Before starting the test, utilize a multimeter to verify that there is zero voltage.

- Only certified electricians should do the work.

- Display caution signs around the testing area.

- Limit the test area to an acceptable range.

Additional Risk-Control Measures:

- Prior to energizing, strict supervisor verification is required.

- Workers receive frequent safety training sessions.

Action Officer & Follow-Up:

In charge Supervisor/Worker

2). Installation of Gland

The sharp edges of the gland openings can injure hands and fingers.

Accident Possibility/Persons at Risk:

- Workers are responsible for gland installation.

- Existing Risk-Control Measures:

- Before you fit the gland, remove any burrs or sharp edges.

- Offer gland installation training classes.

Additional Risk-Control Measures:

- Wear protective gloves.

- Ensure that the worksite is illuminated.

Action Officer & Follow-Up:

In charge Supervisor/Worker

3). Cable Termination

Hand and finger injuries occur during the cable stripping & crimping activities.

Accident Possibility/Persons at Risk:

- Workers handle electrical cables.

Existing Risk-Control Measures:

- Wear appropriate gloves for the hand protection.

- Hands must not be near the crimping points.

- Provide cable termination safety instruction.

Additional Risk-Control Measures:

- Implement hands-on the safety training prior to work execution.

Action Officer & Follow-Up:

In charge Supervisor/Worker

4). Completion of Cable Termination

Working with damp hands or being exposed to moisture can result in an electric shock.

Accident Possibility/Persons at Risk:

- All employees in the electrical workspace.

Existing Risk-Control Measures:

- Maintain good housekeeping inside the equipment.

- Before leaving the worksite, make sure the surrounds are completely dry.

Additional Risk-Control Measures:

- Prior to operation, implement moisture detection methods.

- When working in humid environments, always use insulated tools.

Action Officer & Follow-Up:

In charge Supervisor/Worker

References

- NEC (National Electrical Code) Guidelines.

- IEC 60364: Electrical Installations in Buildings

- OSHA’s Electrical Safety Standards

- NFPA 70E: Standard for Electrical Safety in the Workplace

- Company Safety Policy and Procedures

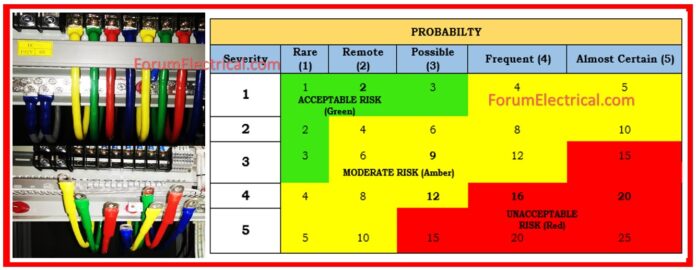

Risk Assessment

Conclusion

This risk assessment provides a secure and effective cable termination process, which reduces the hazards associated with electrical operations.

Strict adherence to safety rules, as well as periodic reviews, can help to ensure workplace safety.