- Define Lock Out Tag Out (LOTO)

- Importance of LOTO

- What is a “locked tag” and why is it included on electrical equipment?

- How does a lockout differ from a tagout?

- Procedure for Energy Control

- Implementation of Lockout and Tagout procedures

- Lockout and Tagout Procedure

- Requirements of Lockout and Tagout Tag

- Limitations on Tags

- General Electrical Safety

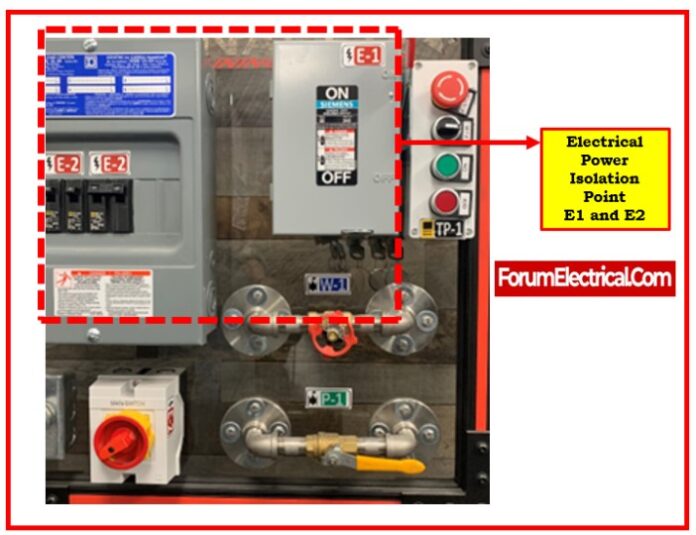

- What is meant by an Energy Isolation Device?

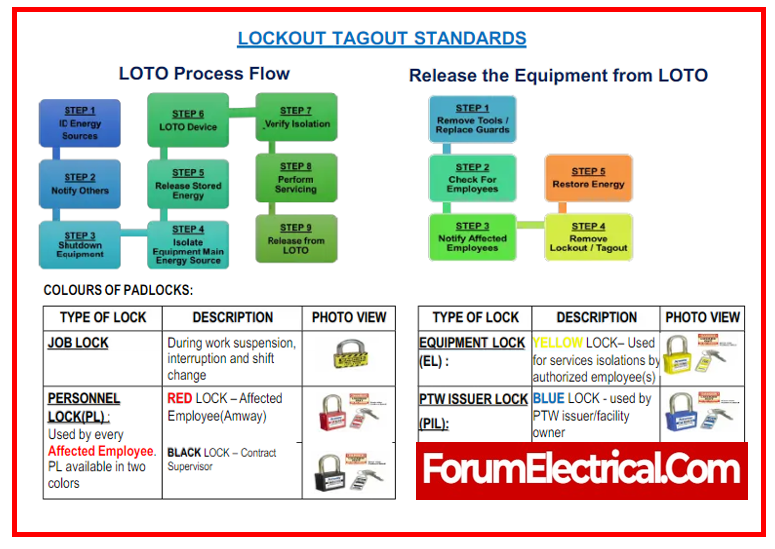

- Lockout Lock and Tag Colors

- Conclusion

Define Lock Out Tag Out (LOTO)

A lockout/tagout system protects against unexpectedly coming into contact with potentially harmful energy from machinery and equipment. A tagout device, or a tag, alerts employees against to use the equipment, while a lockout device, such a padlock, protects the energy isolating device.

The physical shutdown of all potentially dangerous energy sources that power part of machinery, equipment, or a system is known as LOTO (Lock Out Tag Out). Putting a warning tag on the actual restraint device is another aspect of LOTO.

Importance of LOTO

When performing maintenance or repairs on machinery or equipment, one of the most prevalent hazards that can occur in the workplace is the accidental discharge of excessive amounts of energy. If the appropriate safety precautions are not followed, this has the potential to result in severe injuries or even fatalities. The adoption of lock out tag out (LOTO) protocols is an essential safety measure that should be taken to prevent mishaps of this nature. LOTO is an abbreviation for “lockout/tagout,” which stands for “locking and isolating to prevent operation,” and it is used to limit the likelihood of accidents & injuries. It also lessens the need for pricey repairs (or) replacements & increases the amount of time that equipment may be used before needing to be replaced.

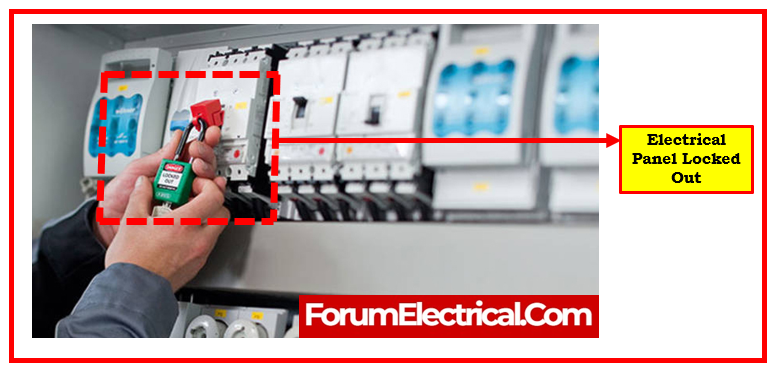

What is a “locked tag” and why is it included on electrical equipment?

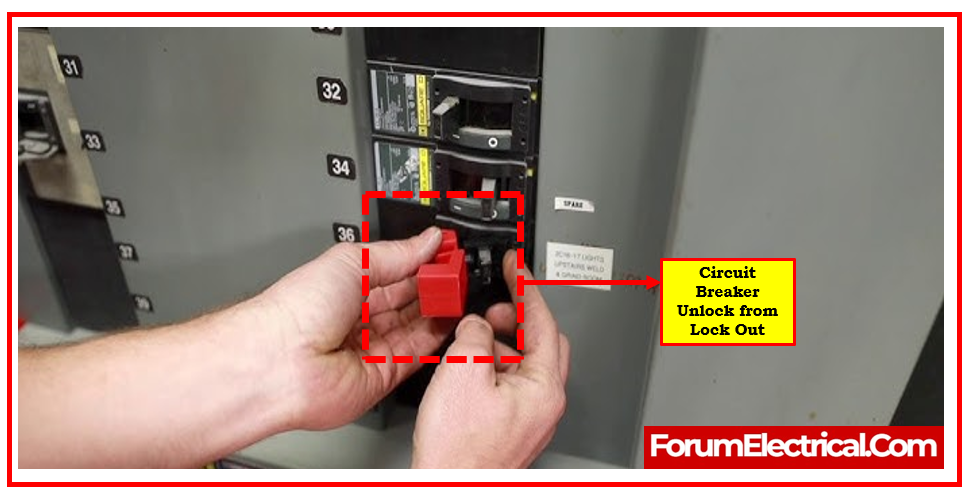

A lockout–tagout device known as the panel lockout can be utilized in order to protect one or more of the circuit breakers located within an electrical panel. It protects the panel cover from being removed and ensures that the door to the panel remains locked. During the time that electrical work is being done, the circuit breakers are left in the off position.

How does a lockout differ from a tagout?

The terms “lockout” and “tagout” are not identical, despite their frequent interchange.

Lockout

When an energy source—mechanical, electrical, hydraulic, pneumatic, chemical, thermal, or otherwise—is physically cut off from the system it powers, such as a machine, part of equipment, or process, lockout occurs. This is accomplished with a range of lockout padlocks & equipment that are ideal for particular uses. For more specialized lockout tasks, devices like circuit breaker lockouts (or) valve lockouts might be utilized.

- Padlocks,

- Blank flanges, and

- Bolted slip blinds

are examples of lockout devices.

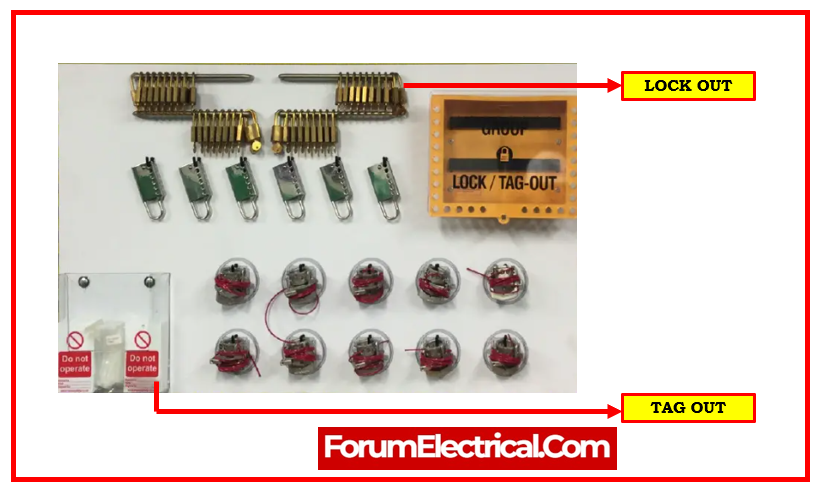

Tag-Out

The process of attaching a label, or tag, explaining what is being done to the machine (or) equipment and the purpose for which it is important is known as “tagout.” A tag’s details could consist of:

- Lockout tag with warning or danger

- Guidelines (such as Do Not Operate)

- Objective (such as Equipment Maintenance)

- Time

- Name and/or picture of the designated employee

- A picture of a safety tag station with many of tags on it

Since tagout doesn’t provide an actual way to stop equipment from re-energizing, it is not advised to use it alone. Energy isolation points have been updated or rebuilt to accommodate the installation of safety padlocks since the lockout tagout standard was introduced in 1989. Additionally, new devices have been created for replacing energy sources in order to comply with the standard.

Lockout and tagout provides improved protection for employees against re-energization when combined and applied to a padlock.

Procedure for Energy Control

Employees performing maintenance on machinery, equipment, and processes containing potentially dangerous energy sources are safeguarded by the Lockout / Tagout written program energy control procedure.

Implementation of Lockout and Tagout procedures

The following are examples of when lockout/tagout procedures are used:

- It is not necessary for a part of machinery to have its power on in order to carry out a work.

- There is always the risk of getting hurt or becoming stuck in some kind of moving gear.

- In the case that machine guards (or) other types of safety devices are removed or bypassed in any way

- When the equipment that was jammed is being freed out

- If the power is turned on to the component of equipment, there is a danger of personal injury.

Lockout and Tagout Procedure

A machine or its circuitry cannot be powered down by lockouts or tagout independently. For equipment lockout/tagout, OSHA (safety standard) recommends a standard protocol. The equipment is tested and turned off before lockout is executed and tags are affixed.

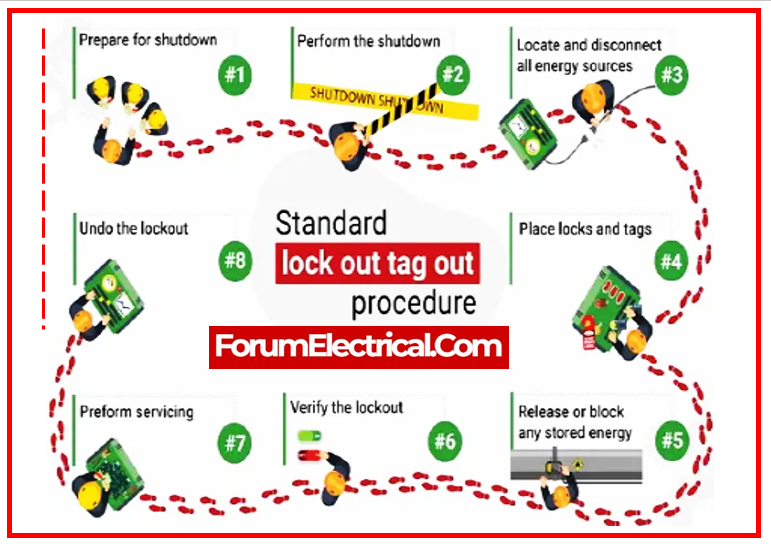

Lockout/tagout protocols used typically in following steps:

Step 1: Shutdown Preparation

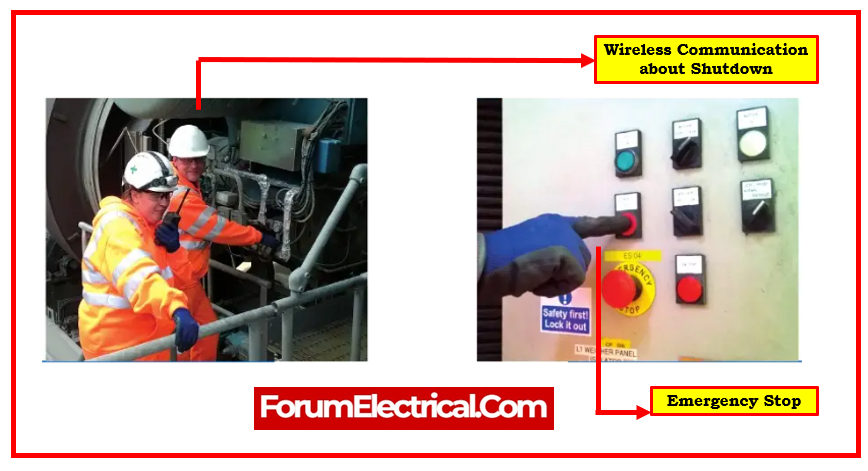

Before initiating a lockout/tagout procedure, determine the type and amount of energy produced by the equipment, and study the proper protocols. Notify everyone at work of the impending downtime. Notifying individuals ahead of time decreases the possibility of an unintentional restart.

Preparation is the initial stage in locking & tagging out equipment during service and maintenance. The authorized personnel must investigate and get a comprehensive understanding of all types of dangerous energy that may be managed during the preparation phase. Furthermore, it is essential to identify specific threats as well as procedures of regulating that energy.

Step 2: Shutdown Equipment

Each part of equipment will require a unique shutdown procedure. Don’t anticipate that which works for a single unit of equipment to work for all of them. Specific shutdown instructions will be included in the energy control processes.

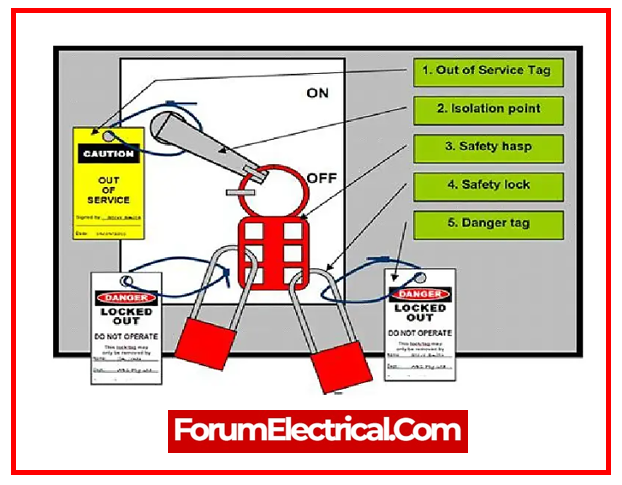

Step 3: Power source isolation using an energy isolating device

Make sure to have located every energy source connected to the machinery. Certain types of equipment require each of their many energy sources to be recognized and segregated from the rest of the device independently.

If an energy-isolating device has a locking mechanism built in, like a hasp, or if it can be locked without needing to be disassembled, rebuilt, or replaced, it can be locked out.

Step-4: Apply Lockout and Tagout devices

Locks and tags can only be affixed by authorized personnel, and the only person with the power to take them down is the one who originally attached them.

- Locks make sure that no one can turn on the power supply. When using locks, tags should be utilized to alert staff members to the lockout as well as identify the authorized worker who installed the lock.

- If the equipment can be locked out, locks must be utilized.

- Place the tag in the same spot where the lock would have located.

- Securely fasten it so it cannot be unintentionally removed.

- Position the tag so that anyone trying to control the equipment understands that moving the device from the “off” position is prohibited.

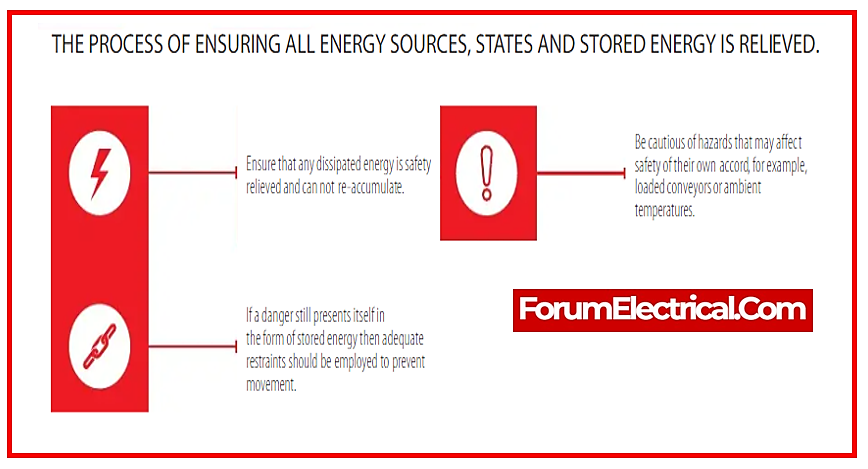

Step 5: Discharge Accumulated Energy

The authorized worker must make sure that the equipment is free of any potentially dangerous energy once the lockout/tagout mechanisms have been used. If all of the energy is not released, shut-down equipment might still cause injuries or fatalities to workers.

Step 6: Verification of Isolation

Making sure is the primary objective of this final stage.

Making confirmation of turned off the machines or devices, disconnected them from the power supply, secured the doors, and inspected them for potentially dangerous residual electricity. However, this is the appropriate time to confirm that everything was done correctly and that using the machine or other equipment is safe at this point.

An authorized worker now confirms that the equipment has been correctly isolated and de-energized.

Step 7: Conduct Maintenance Activity

Start & complete the maintenance that resulted in the system being locked out.

Step 8: Remove any lockout or tagout devices

When the systems are ultimately ready for use, remove the lockout tagout equipment’s by executing this general procedure:

Examine the work Area: The work area needs to be examined prior to the afflicted equipment being fully restarted.

Employee notification: Before removing any equipment, make sure everyone else is out of the way and let them informed when it’s safe for them to return.

Disconnect devices: The authorized worker has to make sure the equipment is safe to be reenergized. They have to make sure that the equipment is in the same condition as it was before the procedure, that safety guards have been replaced, and that tools, spare parts, & debris have been cleared from the area. A device can only be taken out by the person who attached it.

Test the equipment: Use the same processes for restarting, testing, and carrying out the six lockout/tagout phases if the equipment that is being locked out or tagged out needs to be tested.

Requirements of Lockout and Tagout Tag

Standardized: Only make use of locks and tags with the same size, shape, and color. The tags must have the following words: “Do Not Start,” “Do Not Open,” or “Do Not Operate.” They must also have the same print and format.

Identifiable: Anybody trying to operate the equipment should be able to quickly recognize the locks or tags. Never utilize a lockout (or) tagout device belonging to another employee. Every authorized worker needs to have a unique lock and key that they can identify.

Durable: Only bolt cutters or similar tools may be used to remove lockout devices. Devices for lockout and tagout must be able to endure the conditions in which they are used.

Not applied to any other objectives: It’s important to avoid using lockout/tagout tools for unintended purposes. If not, someone can get confused and try to turn on machinery that is being repaired or maintained.

Limitations on Tags

- Tags are simply intended to serve as a warning that an energy-isolating equipment has been turned off. They do not provide the same level of security as a lock.

- Equipment that has been tagged may still be started up, which could cause harm or even death when servicing or maintaining the equipment.

- Tags by themselves give rise to a false security. It cannot be protected from an unintentional startup by tags. So, merely alert employee that personal working on the equipment.

General Electrical Safety

Some general safety advice for handling electrical tools, wires, and circuits is provided below.

- When doing any electrical work, make sure to have on all the necessary personal protection equipment (PPE).

- Make that every electrical appliance is set up and operated correctly.

- Make appropriate use of guarding, insulation, & overcurrent protection devices.

- A vital component to lowering electrical risks is grounding.

- To function as a circuit breaker and stop the current flow to electrical circuit, install ground fault circuit interrupters, or GFCIs.

- It is possible to lessen the possibility of high currents in the wiring which could start fires by using the proper size fuse.

- Keep both hands dry when handling electrical outlets.

- Water is an electrical conductor;thus, any wet or damp places should be dried up before performing any electrical work.

- Make sure that aware of the locations of electrical panels, fuse boxes, and circuit breakers in order to turn off the power in an emergency.

- If see a coworker suffering from an electrical shock, keep him away from any electrical equipment, wires, etc. and use a non-conductive object, such as a plastic stick or piece of wood, to help them recover. Turn off the electricity immediately, if at all possible.

- Attach a “Do Not Use” tag (or) a broken equipment tag.

What is meant by an Energy Isolation Device?

These devices enhance in the safety of energy isolation points.

- Electrical lockout devices are employed to protect the electrical power of equipment when it is in the “off” position.

- Multi-purpose cable lockout devices are frequently used to secure multiple energy isolation points.

- Valve lockout devices are utilized to conceal (or) physically prevent valves from operating.

- Selector switches, push buttons, & other control circuit type devices are NOT considered energy isolating devices.

Lockout Lock and Tag Colors

OSHA has not standardized lockout lock and tag color coding, however common color codes are:

| Color | Tag | Tag Detail | Application |

| Red |  | Personal Danger Tag (PDT) | Lockout device with a red lock, which can only be used by authorized personnel during maintenance. |

| Orange |  | Group isolation (or) lockbox tag | The color orange represents the lock that a group isolator will use to denote when it is okay to undertake maintenance. |

| Yellow |  | Out of Service Tag (OOS) | The affected employee must use the yellow lock to lockout the device before maintenance can be performed. |

| Blue |  | commissioning and test tag | When there are more than six isolation points in a lockbox, a blue lock is used in place of an orange lock. |

Conclusion

Electrical maintenance involves more than simply replacing all outdated electrical components; it also includes electrical system inspection, testing, and monitoring to keep systems and machinery functioning properly. It is essential in addition for the safety of the equipment, but also for the safety of industrial facilities and, in particular, the workers engaged.

Hopefully, that this post has made it evident that providing safety necessitates taking safety precautions. This means that no electrical maintenance should ever commence without appropriate planning and the use of safety lockout equipment.