Regular inspection & testing of electrical panels is essential for assuring safety, dependability, and peak performance in any electrical system.

This detailed electrical panel testing checklist explains the most important areas that must be assessed during the testing procedure.

It is divided into bi-monthly, monthly, & hourly checklists to ensure comprehensive testing at various intervals.

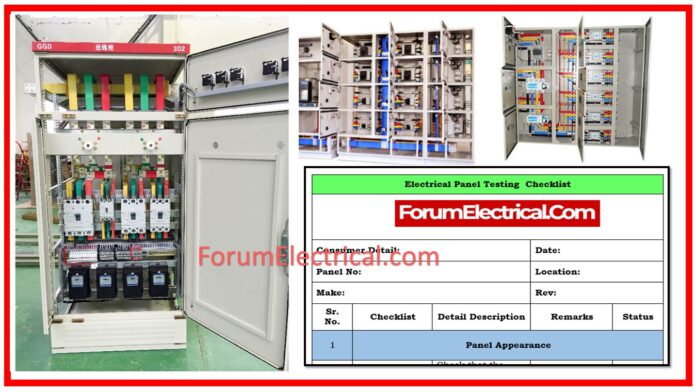

Electrical Panel Testing Checklist

Panel Appearance

Before getting into the fundamental components, it is essential to check the external aspect of the electrical panel. This includes:

- Dimensions: Check that the panel’s width, height, and depth correspond to the General Arrangement (GA) drawings.

- Paint/Color: Make sure the panel’s paint (or) color matches the specifications.

- Sheet Thickness: Check that the thickness of the panel’s sheet fulfills the required specifications.

- Mounting/Fixing Arrangement: Confirm that the panel is installed at the proper angle & height (1.5 to 2 feet).

- Nameplate: Make sure the panel is identified with a nameplate for easy identification.

Electrical Component Inspection

Thorough testing of all electrical components inside the panel is essential to making sure that they correspond with the design & requirements.

- Switchgear Make: Ensure that all switchgear utilized is consistent with the Bill of Materials (BOM), and that specified brands such as L&T are used.

- Switchgear Ratings: Confirm that contactors, relays, MCBs/MCCBs, CTs, & busbars are properly rated according to the designs.

- Internal Arrangement: Ensure that the internal component layout matches the wiring diagram.

- Instrument and Components: Confirm that all needed components, such as the incomer MCB/MCCB, ammeter, voltmeter, & phase indicators, are properly installed.

Electrical Wiring Evaluation

Electrical wire integrity is essential for panel functionality.

- Internal Wiring: All power & control wiring follows the schematics.

- WLC & Timer Wiring: Inspect the wiring for the water level controller & blower timer.

- Power & Control Terminal: Verify the proper installation of power & control terminal strips, as well as the right wiring termination.

- VFD Panel Testing: For VFD (Variable Frequency Drive) panels, check the drive ratings and wiring according to the designs.

- PLC Panel Testing: If a PLC (Programmable Logic Controller) is utilized, ensure that it is properly programmed and that the logic operates as intended.

Power Supply Inspection

The power supplies in the panel must meet the system’s requirements.

- Power Supply: Check that the level controller, indicators, & switches all have the required single-phase power supply.

- Spare Terminals: Ensure that spare terminals are accessible for subsequent use or expansion.

Test Certificates

To ensure compliance as well as quality assurance.

- Test Certificates: Request test certificates from vendors for motors, VFDs, & switchgear to prove that the components have completed the relevant evaluation accreditation processes.

Electrical Panel Monthly Checklist

Periodic inspections are required to ensure the condition & safety of the electrical panels.

The following are important things to address during the monthly inspection:

- Ensure that the main power line & outgoing cables are grounded in accordance with safety rules.

- Confirm that high voltage signage is plainly visible.

- All outgoing circuits must be properly grounded and equipped with circuit breakers.

- Identify all power distribution boards with a schematic specifying the power source.

- Use an earth tester to measure ground resistance.

- Check that a fully charged fire extinguisher is located near the panel.

- Display the names & contact information for qualified persons on the panel board.

Electrical Panel Hourly Checklist

Regular, short-interval checks are required to continuously monitor panel conditions during operation. These inspections usually include:

- Inspect the panel box to ensure it is properly locked.

- Check the state of the panel’s light indicators.

- Ensure that the breakers are working properly.

- Inspect the wiring connections and ensure there are no evident flaws.

- Check that the panel is properly isolated and grounded.

By following these principles, you may ensure that electrical panels remain safe and reliable in any structure. Regular inspections assist to avoid accidents, downtime, & costly repairs by spotting problems very early.