Ensuring the safe running of electrical infrastructure at industrial and building sites depends extensively on electrical safety inspections.

This checklist gives an organized way to assess several electrical components, therefore providing adherence to safety criteria and reducing hazards.

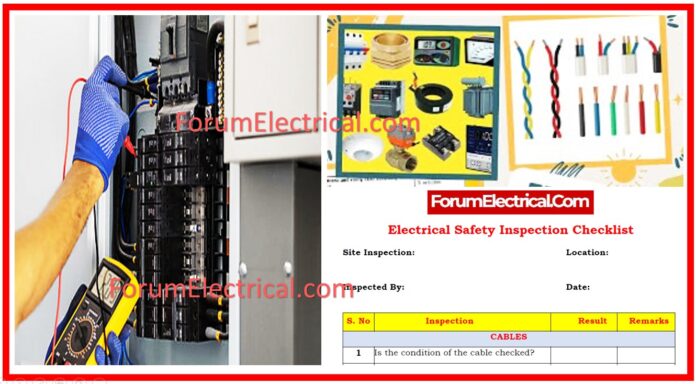

Sites Inspection Information

For accurately document site inspections, essential information are included. The inspection site is specified to clarify the area being assessed.

An engineer or staff member responsible for site electrical safety & compliance reviews the inspection.

Recording the inspection date helps manage maintenance schedules, identify reoccurring concerns, and take appropriate corrective action.

Documenting these information helps maintain safety standards & supports audits and compliance inspections.

Classification of Inspections

Cables

Any power distribution system depends on electrical cables as fundamental parts. Correct inspection guarantees their safe running condition and integrity.

- Look for physical deterioration, wear, and hazardous condition exposure on wires in your system.

- Testing cables provided from other sites before usage helps to prevent insulation failure by means of insulation resistance (IR) testing.

- Check whether main wires follow site safety guidelines by seeing whether they are buried underground or above.

- Check if welding cables are raised above ground to prevent tripping hazards.

- Make sure the electrical wires and welds are not overlapping to stop overheating and electrical failures.

- Determine any inappropriate joints that can cause risks or electrical failures in cable joints.

Distribution Boards (DBs) & Sub-Distribution Boards (SDBs)

Electrical circuit breakers & fuses found in DBs and SDBs guard the electrical system against overloads and failures.

- Check that for good grounding the earth conductor stretches correctly to DB/SDB.

- Make sure DBs & extension boards stay free from water damage.

- Check for indicators of DB (or) SDB overloading that can cause fires.

- Verify whether the suitable fuses & circuit breakers are used to guard electrical circuits.

- Make that electrical wires in junction boxes, CB panels, & other like areas are correctly insulated.

Earth Leakage Circuit Breaker (ELCB)

An essential safety tool, an ELCB detects leakage currents to prevent electric shock.

- Check that for maximum safety all electrical connections travel via an ELCB.

- Maintaining ELCB sensitivity at 30mA will help you to find even modest leaks.

- Frequent testing and documentation guarantees that ELCBs are numbered, tested regularly, and logged in a logbook under countersignature from a certified inspector.

Earthing

Good grounding of the electrical systems lowers the equipment damage and electric shock risk.

Make that every earthing connection in the system is constant and strong.

Electrical Machines & Accessories

Electrical machine and accessory inspection ensures their effective and safe running conditions.

- Check sure plug caps are available everywhere needed.

- Make that every metallic component in an electrical equipment, light fitting, and accessory is correctly grounded.

- Check whether the shelter covering welding machinery is sufficient to guard against environmental exposure.

- Make sure portable power tools are kept in line with industry safety criteria.

Inspection Results

- Y-Yes: The need is satisfied.

- N – No: There is not the necessary criteria fulfilled.

- NS – Not Satisfactory: The state is insufficient and requires improvement.

Notes for Reference

Any other comments from the inspection engineer about noted problems or required fixes.

Following this checklist helps companies to guarantee regulatory compliance, keep electrical safety requirements, and lower dangers.