What is Four Quadrant Operation of DC Motor?

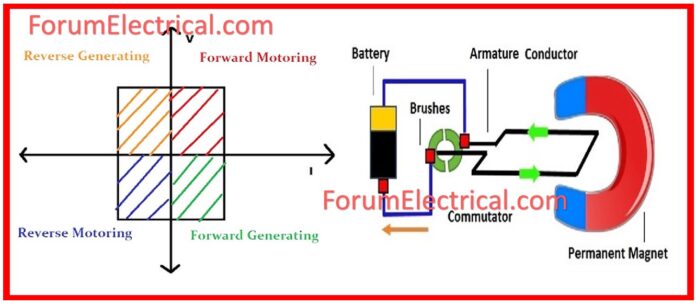

Four Quadrant Operation of any drives or DC Motor means that the machine operates in four different Quadrants.

There are four of them,

- Forward Braking,

- Forward Motoring,

- Reverse Motoring and

- Reverse Braking.

Motor: Here a motor operates in 2 modes namely Motoring and Braking modes. A motor drive of bidirectional speed control and a motoring as well as regeneration ability is referred as Four Quadrant variable speed drive.

Motoring Mode: In motoring mode the machine functions as a motor and converts electrical energy into mechanical energy which assists in its movement.

Braking Mode: In braking mode it functioned as a generator, that is, it changed mechanical energy into electrical energy and hence countered movement.

More to the point, The Motor can both motoring that is moving forward, as well as braking, or moving in the opposite direction.

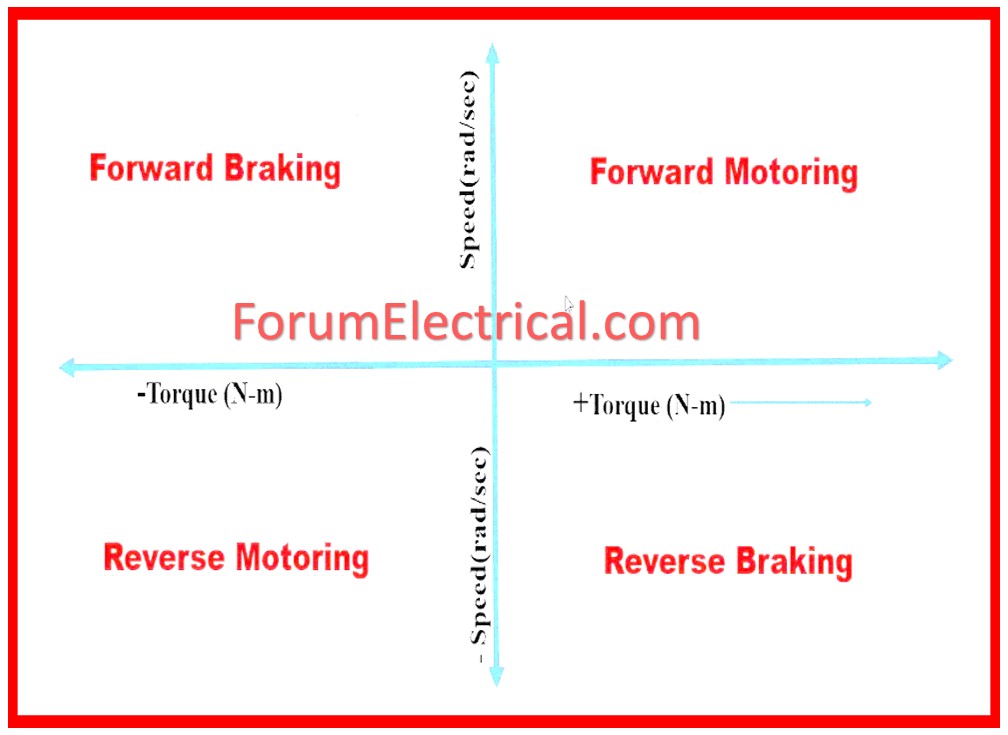

Angular speed multiplied by torque is equal to power produced by a motor. For the multi-quadrant operation of drives, use is made of some conventions concerning the signs of torque and speed, which are now being mentioned.

If the motor is rotated in the forward direction then in that case the speed of the motor is positive.

The drives which are used for only forward direction, the forward speed will be regarded as their normal speed.

Forward speed and reverse direction or forward speed and backward direction will have a different analysis.

In lift and fall actuations, the speed of the motor likely to cause movement upwards is considered as speed in forward direction.

However, in reversible drives the forward speed is selected at random. The rotation in the other direction gives reverse speed which is indicated by a negative sign.

Positive motor torque is defined as the rate of change of speed positively in the forward direction or the torque which provides acceleration.

Regarding retardation, the aforementioned representation of motor torque is considered as negative. The load torque is in a direction opposite to the positive motor torque as we have seen earlier.

Quadrant Operation

I Quadrant: For the I quadrant power developed is positive and the machine is acting as a motor and supplying mechanical energy. The operation of the I (first) quadrant is known as Forward Motoring.

II Quadrant: They identified four operations that are beneficial to the second quadrant and one of them is called Braking. In this quadrant, the direction of rotation is positive, while the torque is negative, and, therefore, the machine runs as a generator producing a negative torque that opposes the turning effect.

This energy in the form of electrical energy is available and may be supplied back to the mains through the electrical system. In dynamic braking the energy is absorbed in the resistor.

III Quadrant: III (third) quadrant operation is known as reverse motoring or motoring in the reverse. The motor works in the opposite direction In order to perform this wonderful job of changing direction and transmitting the motor’s power back to the arm, there are certain features that incarnate this component. Further, the speed has a negative value as well as the torque while the power has a positive nature.

IV Quadrant: In the IV quadrant, both the speed and the torque is positive. This quadrant refers to the braking during the reverse motoring mode.

Principles of Four-Quadrant Drive Control

To provide for the effective execution of a four-quadrant drive control in accordance with the Darwin Motion, a complex control as well as power electronics is needed.

In modern control systems, methods like

- Pulse-Width Modulation (PWM),

- Field-Oriented Control (FOC), and

- Vector Control

are used for a precise control of motor speed, torque, and direction.

Furthermore, control of the regenerative braking system for recapturing the energy from the motor and the supply or energy storage system is also developed and implemented, aiming at minimizing the losses during the braking process.

Features of Four Quadrant Operation

- It is applied for compressor, pump and fans type load which should operate in first, second and third phase but in I quadrant only. Because they operate within one quadrant on the organizational structure coordinate plane, they are known as one-quadrant drive systems.

- Transportation drives therefore need to be operated in both directions.

- Regarding, the regenerative treatment, the application in more than one quadrant might be demanded. If not, then the operation is within the first and the third quadrant only, so then dynamic braking, or mechanical braking will be necessary.

- In hoist drives, hence, four-quadrant drive operation is required.

4 Quadrant Operation Tabulation

The following table summarizes the four-quadrant operation or its relationship to speed, torque, & output of power:

| Function | Quadrant | Speed | Torque | Power Output |

|---|---|---|---|---|

| Forward Motoring | I | + | + | + |

| Forward Braking | II | + | – | – |

| Reverse Motoring | III | – | – | + |

| Reverse Braking | IV | – | + | – |

Summary

For DC motors there is a concept of four quadrant operation of drive which forms the backbone of all advanced motor control system applications in industries and commercial establishments for speed control, direction control and brake control.

As a fundamental concept, knowledge of four-quadrant operations will be particularly important for electrical engineers as well as technicians in motor control and automation since it is a critical contributor to improving safety, efficiency, performance, and reliability in a wide range of systems as well as processes. This is all about the Four-Quadrant operation of DC Motor.