The datasheet specifications address the design, manufacture, packing, and supply of a flameproof, weatherproof high voltage induction motor and associated accessories to power the required mainline load.

General

The motor & its components, parts, and auxiliaries must be manufactured and designed so that they can be interchanged in any vendor’s product of the same class, size, and form. The seller shall use only high-grade materials, & the technicians employed will be of the highest quality recognized internationally.

Site Condition

The motor must be able to operate satisfactorily in the humid and extremely corrosive atmosphere found in refineries & other petroleum operations.

- Ambient temperature: 50°C to 500°C

- Humidity: 98%

- Altitude: < 1000 meters above mean sea level (MSL).

Important Technical Information

Name Plate Details

The following information must be on a corrosion-resistant stainless-steel nameplate that is attached to the motor’s body in a prominent location.

- Manufacturing name

- Frame size and serial number

- Duty

- Voltage

- Current

- Frequency

- Rated KW

- Number of phases

- RPM at full load

- Insulation level

- Maximum rise in temperature

- Type of cooling

- Tag. No. (must be provided by the Owner upon acceptance of the drawing)

- Order for Owner’s Purchase No.

- Any additional features that the manufacturer considers appropriate.

Winding Temperature Detectors

The motor must have a 100Ω platinum (RTD) and3.85 x 10-3 temperature coefficient. RTDs should measure winding temperature in acceptable locations.

It must be placed 120 °C apart between the coil sides to measure winding temperature and at the base of the slots to measure core temperature.

The Owner’s remote controller unit will be connected to the temperature detectors’ terminal box. The tender describes this terminal box.

Bearing Temperature Detectors

Resistance-type temperature detectors must be provided for both DE and NDE. The Instrumentation portion of the tender contains information about the temperature measuring device and their termination.

Terminal Box

Non-tracking fireproof & non-hygroscopic bushing with properly sized bolted anti-vibration terminals will bring the winding ends into the terminal box. The terminals must be well-designed to prevent vibration-induced slackening and clearance loss. Insulate line terminal from frame. From the driving end, the terminal box is on the motor’s right.

Bottom cable entrance requires an EEx(d) terminal box. A bushing in a flameproof termination box will bring out the star windings’ neutral point for differential protection. The housing must be flameproof/explosion-proof.

CT will be supplied by the vendor. CT ratio, burden, short time rating, etc. will be finalized during detail engineering.

Terminal boxes and cable entry must be flameproof and explosion-proof certified as EEx(d).

Clearances &creepage distances between active components and earth must be maintained. The motor terminal box must resist a 0.25-second 3-phase short circuit at the motor terminals.

Cooling

Motor must be cooled by a fan. Airflow from the cooling fan must be directed toward the motor load connection. The fans must be made out of corrosion-resistant material, be non-sparking, and be properly guarded by a fan guard.

Space Heater

To prevent condensation during the shut-down period, the motor must include a space heater that is adequate for 240 V single phase. The requirements of applicable IEC/IS regulations must be followed by the heater when installed in a hazardous environment. The heater leads must be terminated in a separate flameproof (EExd) – weatherproof terminal box with a flameproof gland of an NPT size that is appropriate for the cable provided.

Packing

All motors must be safely wrapped in waterproof material, packed in wooden boxes for export, and capable of withstanding handling risks throughout land transport in the country of despatch.

Spares, Tools and Tackles

The vendor must include a list of the unique tools and equipment needed to maintain the motor.

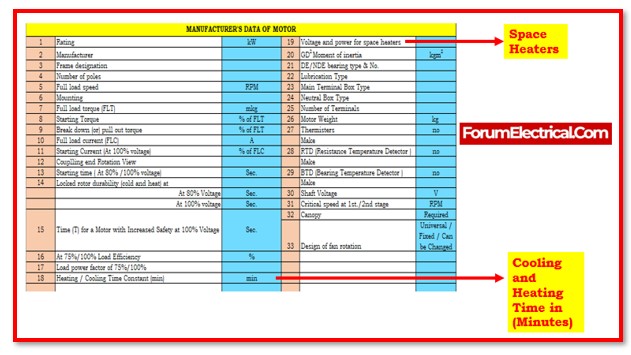

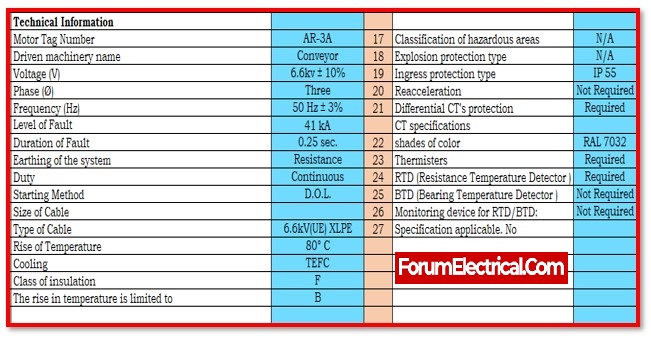

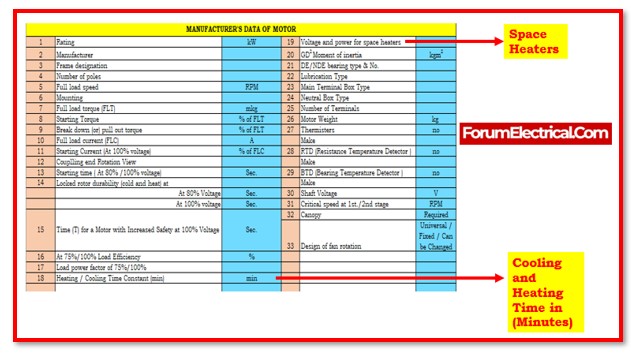

Sample Data Sheet

The manufacturer provides the datasheet for the high voltage induction motor, that can be downloaded and viewed by clicking on the link below: