- What is an alternator?

- Basic Principle of an alternator

- Components of an alternator

- How an alternator works?

- How does the automobile battery get charged by the alternator?

- What distinguishes an alternator from a generator?

- What is the formula for alternator power?

- Different Alternator Types

- Different Alternator Types Based on Usage

- Different Alternator Types Based on Pole

- Advantages of an Alternator

- Disadvantages of an Alternator

- Applications of an Alternator

- Frequently asked Questions

What is an alternator?

The alternator is a type of generator that is responsible for recharging the battery as well as distributing power throughout the vehicle.

Alternators are standard equipment in all automobiles with conventional internal combustion engines, with the exception of a few hybrid types.

Alternators are often located in the front of the engine & have a belt that goes around them. The size of an alternator is comparable to that of a coconut.

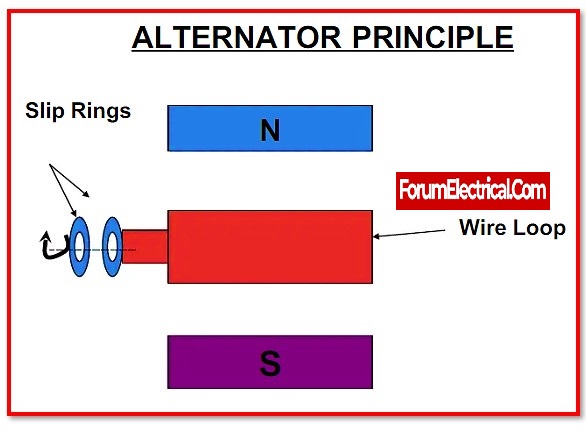

Basic Principle of an alternator

Armature winding & magnetic field are the basic principles of electromagnetic induction, which is the same concept used in DC generators. The construction of an alternator and a DC generator differs significantly.

The armature spins while the field system is stationary in a DC generator.

The armature winding is located on the stator, a fixed component, while the field winding is mounted on the rotor, a rotating component.

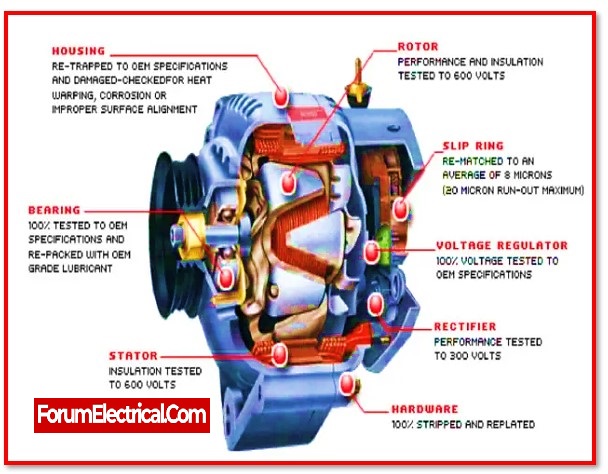

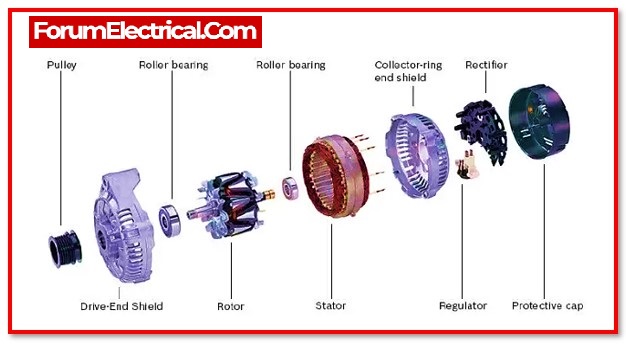

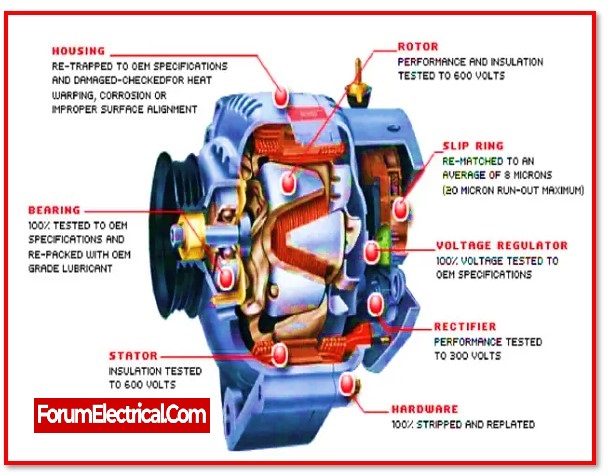

Components of an alternator

1). Voltage Regulator

The voltage regulator is responsible for regulating the amount of power that is sent from an alternator to the battery so that the charging process may be managed effectively. Regulators may be constructed with a variety of purposes, and their operation is determined by the specifications of the device.

2). Rectifier

During the charging process, the rectifier is used to perform the process of converting current from the alternating current (AC) to the direct current (DC).

3). Rotor

The alternator’s rotor is the rotating mass that is found inside the device and is driven to revolve by a pulley and a drive belt system. The rotor performs the function of an electromagnet while it is rotating.

4). Slip Rings

Slip rings are used in order to provide the rotor with direct current & power in order for it to function properly.

5). Slip Ring End Bearing

The spinning of the rotor shaft is supported by the bearings, which have been designed specifically for this purpose.

6). Stator

The stator of an electric motor is made up of a number of wire coils that are coiled around an iron ring. The stator is located on the exterior of the rotor, and electrical current is generated whenever a magnetic field is produced.

7). Drive End Bearing

The spinning of the rotor shaft is supported by the bearings, which are constructed specifically for this purpose.

8). Pulley

The rotor shaft & the drive belt system are both linked to the pulley that is located inside. Because of the rotation generated by the engine, the drive belt system spins the pulley, which is the first step in the charging process.

9). Cooling fan

In order to function well, alternators must be cooled since they deliver a lot of heat. They include revolving fans for additional cooling, in addition to vents and an aluminium body for enhanced heat dissipation. While earlier types often have exterior fan blades, new alternator models feature internal cooling fans.

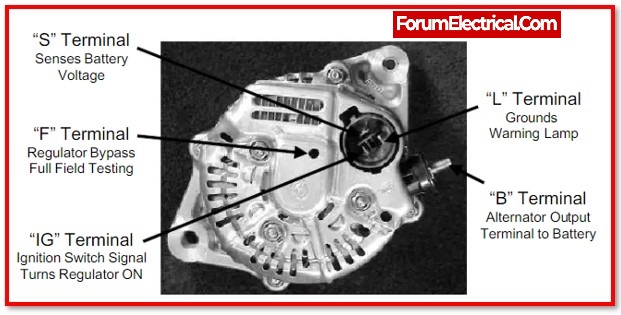

There are multiple terminals on the rear side of the alternator. The following are the most frequent terminals:

Terminal S: Battery voltage is detected.

Terminal IG:The ignition switch activates the voltage regulator.

Terminal L: Closes the warning lamp’s circuit.

Terminal B: The primary alternator output terminal (which is linked to the battery)

Terminal F: Regulator full-field bypass

How an alternator works?

While older vehicles could have a separate pulley connecting the engine’s crankshaft to the alternator, modern vehicles use a serpentine belt to power their alternators. The drive belt’s motion causes the stator’s rotor in the alternator to spin rapidly.

The rotor generates electrical energy as it rotates. The magnets around the rotor are strategically positioned to generate a magnetic field as they pass over the stator’s copper wire. The voltage created by this magnetic field is then caught by the stator. The voltage regulator uses this power to distribute energy throughout the vehicle and regulate the voltage applied to the battery.

The starting motor starts the automobile using power from the battery. The alternator produces energy when the automobile is moving in order to power the electrical system & recharge the battery. The alternator functions similarly to the generator. In this instance, the pulley on the alternator is turned by the internal combustion engine of an automobile, which also generates energy.

How does the automobile battery get charged by the alternator?

The alternator and battery operate together to provide energy for the car’s electrical systems. Direct current (DC) is generated by alternators as their output. Alternating current (AC) travels via a magnetic field and generates an electrical current when the alternator pulley is turned. The rectifier then converts this to DC.

Only current that was under external regulation was generated by alternators.

With the emergence of smart charge systems and CANBUS systems, which are now extensively utilised, many new cars adopted a load request type (LRT) charging system. The engine control unit (ECU) of the vehicle is in charge of these systems. The ECU signals the alternator to start charging as the load on the vehicle increases. The alternator must modify its charge rate to accommodate changing electrical loads. Currently, it is simple for these types of alternators to be incorrectly classified as defective if a charging issue with the vehicle arises, although most of the time, no alternator malfunction is found.

What distinguishes an alternator from a generator?

Generators and alternators are both devices that transform the mechanical energy into an electrical energy. Other than that, they are rather different. The magnetic field that revolves around the stationary armature in an alternator, whereas the armature spins inside a stationary magnetic field in a generator.

What is the formula for alternator power?

The alternator voltage output frequency depends on the number of poles and rotor pole rotation speed.

f=NP/120

F – Frequency

N – Rotational speed expressed in revolutions per minute (rpm), and

P – Number of poles.

Different Alternator Types

Different Alternator Types Based on Usage

Depending on their uses and designs, alternators divided into several different categories.

1). Automotive alternators

The alternator and battery operate together to provide energy for the vehicle’s electrical systems. Direct current (DC) is produced by alternators as their output. Alternating current (AC) flows via a magnetic field and generates an electrical current when the alternator pulley is turned.

2). Diesel-electric locomotive alternators

Electric motors located on the locomotive’s axles are powered by electricity produced by an alternator that is driven by the diesel engine. The internal combustion engine significantly outperformed the steam locomotive in terms of efficiency, allowing for significant maintenance, cost reductions and the removal of several infrastructure.

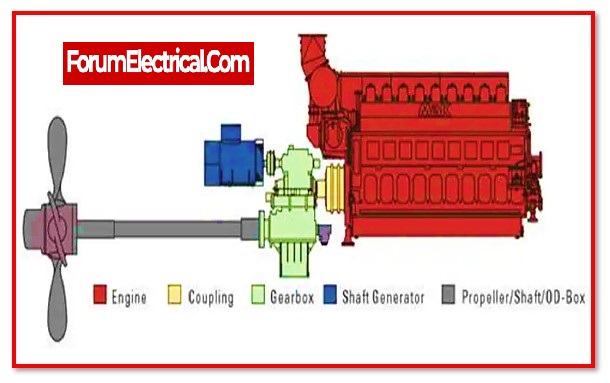

3). Marine alternators

A marine alternator is a device that transforms mechanical energy into electrical current, allowing other equipment to be powered. Because they are waterproof and don’t have any moving components, marine alternators are constructed particularly to function in a maritime environment.

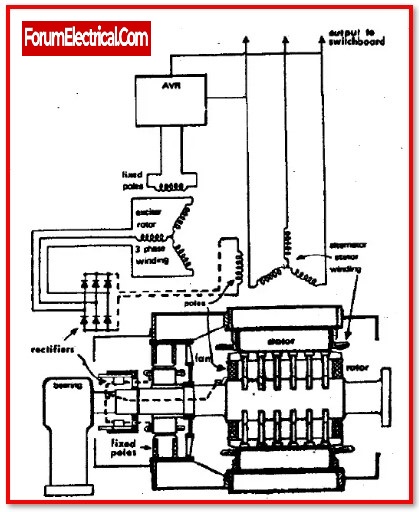

4). Brushless alternators

A brushless alternator generates power using rotors rather than carbon brushes. A brushless alternator comprises no brushes & fewer moving components to maintain or replace. Brushless diesel generators are therefore often more efficient than the brushed alternators.

5). Radio alternators

A radio frequency alternator varied from a standard electric alternator in that it revolved considerably faster & had many magnetic “poles” on the rotor & stator, generally 300 to 600, to produce alternating current of high enough frequency to generate radio waves (radio frequency current).

Different Alternator Types Based on Pole

These alternators may be classified in a variety of ways, but the two primary types based on their design are:

1). Salient Pole Type Alternator

2). Smooth Cylindrical Tye Alternator

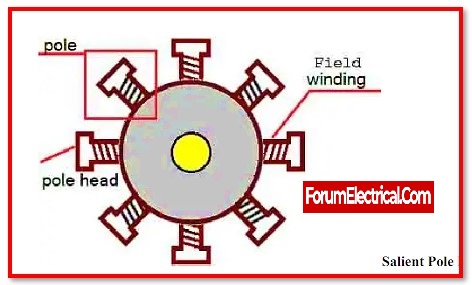

1). Salient Pole Type Alternator

It serves as a low and medium-speed alternator. It features a high number of the projecting poles with their cores fastened or dovetailed (integrated) onto a strong magnetic wheel of excellent magnetic grade cast iron or steel.

These generators are distinguished by their enormous diameters & short axial lengths. These generators resemble a large wheel. These are mostly employed in low-speed turbines, such as those found in hydroelectric power plants.

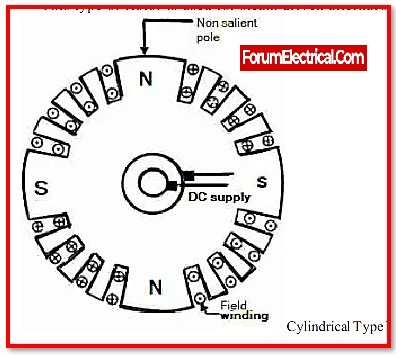

2). Smooth Cylindrical Type Alternator

It is utilised to power a steam turbine alternator. This generator’s rotor revolves at an extremely fast speed. The rotor is made out of the smooth solid forged steel cylinder with slots machined out at regular intervals around the outer circumference to accommodate field coils.

These rotors are primarily intended for 2 pole or 4 pole turbo generators operating at 36000 rpm (or) 1800 rpm, respectively.

Advantages of an Alternator

- Low cost

- Low weight

- Ease of maintenance

- Ease of assembly

- Durability

- Simplification of design features

- Robust

Disadvantages of an Alternator

- Transformers are essential for alternators.

- Alternators will overheat if the current is too high.

Applications of an Alternator

- Several units are operated by diesel power plants

- Electricity-generating plants

- Radio wave transmission

- Automobiles

- Maritime applications.

Frequently asked Questions

1). What are the symptoms of s bad alternator?

Several indications of a malfunctioning alternator

- Dim or very bright lights.

- A dead battery.

- Inefficient or broken accessories.

- Having difficulty starting or frequently stalling.

- Whining or growling sounds.

- Burning rubber (or) wires burning smell.

- Dash-mounted Battery Warning Light.

2). What happens if alternator fails?

If alternator fails to continuously charge the battery, the fuel injectors could fail to fire, causing the engine to stall. A failing alternator can cause a variety of additional electrical problems. In general, such difficulties exhibit as a failure to perform at full power.