A Vacuum Circuit Breaker (VCB) panel is used to protect transformers. VCB panels are carefully engineered to meet high industry standards and are valued for qualities such as superior quality & cost effectiveness.

- Outline

- Key Specifications

- 1). Voltage Rating

- 2). Current Rating

- 3). Breaker Type

- 4). Insulation Level

- 5). Operation

- 6). Panel Construction

- 7). Control and Protection

- 8). Mechanical Endurance

- 9). Environmental Conditions

- 10). Safety Features

- Datasheet

- Advantages of HT-VCB Panel

- Applications of HT-VCB Panel

- Compliance and Standards

- Customization Possibilities

- Points to Remember

- Why is VCB used in HT side?

- What is the size of HT panel?

Outline

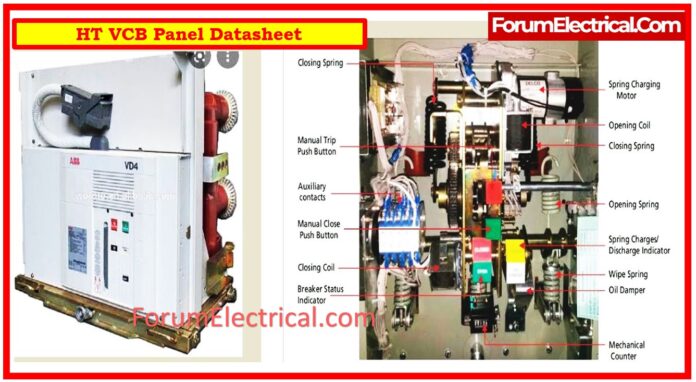

The High Tension (HT) Vacuum Circuit Breaker (VCB) panel is an important component in medium to high-voltage electrical systems.

It is generally used for switching and protecting equipment in

- Substations,

- Industrial applications, &

- Distribution networks.

VCB panels protect electrical systems by halting high-current faults and preventing equipment damage.

They are renowned for their durability, safety, & low maintenance needs, making them an appropriate option for modern power systems.

Key Specifications

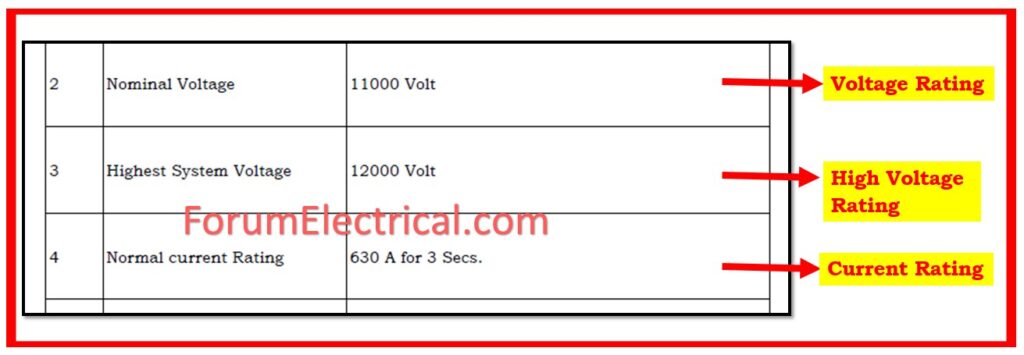

1). Voltage Rating

Rated voltage: 11 kV, 33 kV, or 66 kV (depending on the type).

Maximum operating voltage: 12 kV, 36 kV, 72 kV.

2). Current Rating

Continuous Current: 630A to 3150A.

Short-circuit current: 25kA to 40kA for three seconds.

3). Breaker Type

Vacuum Circuit Breaker (VCB): pole-mounted with (or) without manually operated mechanisms.

4). Insulation Level

Power Frequency Withstand Voltage: 28 kV (1 min)

Impulse Withstanding Voltage: 75 kV

5). Operation

Manual, motorized (or) remote control.

Spring-loaded mechanism with trip-free function.

Close and open coils for remote operation.

6). Panel Construction

Material: CRCA steel sheets.

Protection class: IP4X (IP54 available for outdoor applications).

Finish: Powder-coated with anti-corrosive paint.

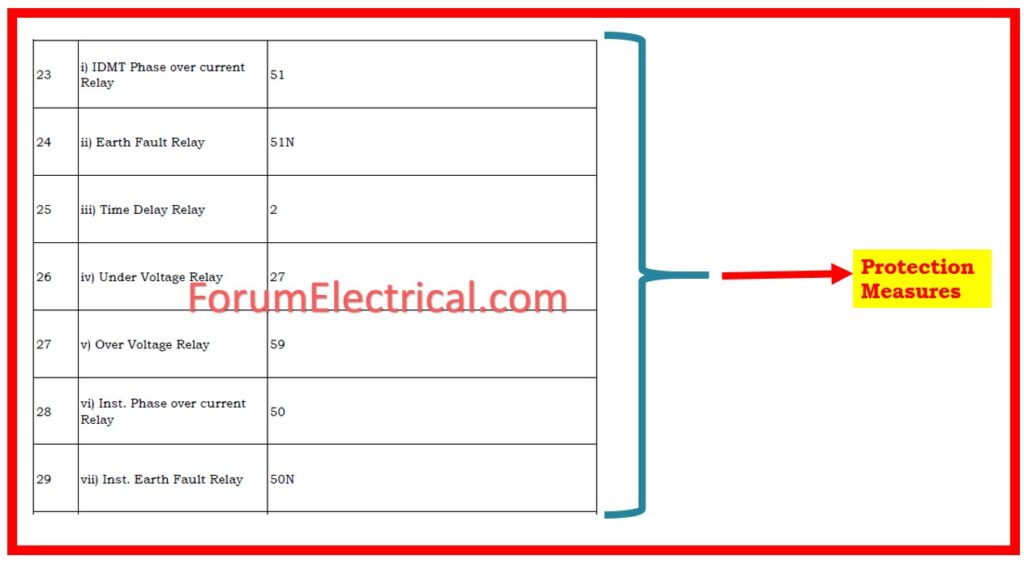

7). Control and Protection

Integrated protection relays (overcurrent, earth fault, and under voltage)

Microprocessor-based relay with adjustable trip settings.

SCADA-compatible control options for remote monitoring.

Potential transformers (PT) and current transformers (CT), as needed.

8). Mechanical Endurance

Breaker Operation: Upto to 10,000 mechanical operations.

Maintenance intervals: Designed for little maintenance, inspection is required after a defined number of operations (or) after lengthy operation.

9). Environmental Conditions

Ambient Temperature Range: -10°C to +55°C

Humidity: up to 95% non-condensing

Altitude: Suitable for installation at elevations up to 1000m above sea level (greater altitudes available upon request).

10). Safety Features

Interlocking systems to prevent dangerous operations

Shutters and padlocking improve operational safety.

Arc-proof design to prevent arc flash occurrences.

Datasheet

Advantages of HT-VCB Panel

- Vacuum circuit breakers provide superior interruption performance and a long service life.

- VCB technology needs less maintenance than oil & air circuit breakers.

- Space-saving panels that may be modified for indoor or outdoor use.

- VCB panels contain no oil or gas, making them environmentally benign and free of contamination threats.

- The robust construction, which includes integrated protective relays, guarantees that the system operates safely even in the most extreme fault conditions.

- VCBs are noted for their short interruption times, which reduces the impact of short circuits.

Applications of HT-VCB Panel

- HT VCB panels are frequently utilized for protection & control in utility substations.

- Appropriate for medium- & high-voltage systems in industries including steel, chemical plants, and cement production.

- Large commercial facilities use electrical distribution & protection.

- Promotes grid integration and protects wind & solar power generation installations.

Compliance and Standards

- IEC 62271-100: High-voltage switchgear and control gear standards

- IEC 60947-2: IEC 60947-2 describes low-voltage circuit breakers.

- IS 13118: Indian Standard for High Voltage Circuit Breakers.

- ANSI/IEEE C37: ANSI/IEEE C37 requirements for switchgear provide IP4X/IP54 protection against dust and water ingress.

Customization Possibilities

- Customizable panel layout for unique application requirements.

- Additional motorized spring charging mechanism.

- SCADA Integration for Remote Monitoring & Control

- Enhanced arc flash protection.

- Ring-main or dual-breaker arrangements

Points to Remember

For additional technical information, model choices, and customization possibilities, reach out to our technical support team.

Why is VCB used in HT side?

Vacuum circuit breakers (VCB) are chosen in high transmission systems due to their

- Improved arc quenching capabilities,

- Higher insulation strength,

- Compact size,

- Lower maintenance requirements,

- Increased reliability and lifespan, and

- Larger interrupting capacity.

What is the size of HT panel?

Specifications

Rated Voltage: 40.5 KV.

- Size 1: 1200 X 2600 X 2400 mm.

- Size 2: 1400 X 2600 X 2400 mm.