To ensure safe and dependable electrical installations and operations, the Indian Electricity Rules, or IE Rules, were developed.

To ensure adherence to safety regulations and legal obligations, these guidelines address a number of electrical system topics, including earthing procedures.

Regulations for electrical installations in India are outlined in the IE Rules, which were created in accordance with Section 37 of the Indian Electricity Act 1910.

They primarily outline safety regulations for electrical energy production, transmission, distribution, and consumption.

The IE Rules 1956 outline certain earthing requirements for low, medium, high, & extra-high voltage installations.

Following these guidelines improves the dependability of electrical systems, prevents shocks, and regulates transient overvoltages.

Electrical Rules in India

According to I.E. Rules 1956, installations must follow the Indian Electricity Rule 1956 (as revised from time to time) and the National Electrical Code, which include safety standards for electricity delivery and consumption.

Pressure & Frequency Of Supply

All current-consuming devices must meet the specified pressure & frequency of supply.

Wiring System

The terms and conditions specify the wiring system to be used. “Power wiring must be kept separate & distinct from lighting wire.

Conductors should be routed along walls and ceilings to allow for easy inspection. The Engineer should plan ahead of time to balance circuits in three-phase systems.

Conductors

Conductor materials and sizes must meet Bureau of Indian Standards and I.E. Rules, 1956 requirements.

All cables must have the maker’s name and identity printed on the insulated surface. In case of disagreement, the provider must prove that the material is original to the company.

Materials

In electrical installations, all materials, fittings, equipment, accessories, and appliances must meet Bureau of Indian Standards specifications.

If there is no Indian Standard, materials and things must be approved by the relevant body alternatively.

Testing Procedure

Before putting an installation permanently into service, the following tests must be completed

Insulation Resistance

To measure insulating resistance, apply a direct current pressure of at least twice the working pressure to the earth and any component of the conductor system, including all fuses and switches. The working pressure will be considered to be that It is positioned across the outer phase conductors & the neutral.

The insulation resistance (IR) of an installation measured above must not be less than 25 mega ohms divided by the number of circuit points, provided that:

- No installation shall be required to have an insulating resistance larger than one mega ohm.

- Lighting circuits must be checked with all lamps in place, except in cases of earthed concealed wire.

- To test heating and power circuits, disconnect the appliance from the power supply.

Earth Resistance

The suggested value for any earth system is 50, unless otherwise specified. Choose corrosion-resistant materials appropriate for the soil type.

The electrode should be kept free of discomfort, enamel, and grease. The earth continuity conductor needs to be at least 14 SWG (2.8.94 square millimeters).

The earth’s resistivity test shall be carried out in conformity with the Indian Standard Code (IS Code) of Practice for Earthing.

Fans & Regulators

Ceiling fans must be wired to a ceiling rose, hanging from a hook or shackle, and properly insulated.

Suspension rod joints must be screwed and split pins should be used to fasten connecting points.

Conduit System of Wiring

Electrically continuous conduit from distribution board to outlet boxes for the lighting, switches, and appliances.

Screw sockets are used to link conduit lengths.

Threads must be clear of grease and oil, and no such materials may enter the conductors.

The conduit system must be electrically continuous and properly connected to the earthing system.

Excavation & Back Fill

The service provider must follow the plans and standards for excavation, backfilling, shoring, and strutting during cable installation.

Trenches must be filled in layers that do not exceed 150 mm.

Before laying the next layer, the previous layer must be well pushed and cemented.

The contractor is responsible for restoring any excavated surfaces, roads, sidewalks, curbs, and walls to their original state, as determined by departmental officers.

Cable Test

Before laying cables, the following tests must be performed.

Before and after joining, conduct insulation tests between phases, phase, and earth on each length of cable.

After cable laying, the Department will execute the following tests in its presence.

- Insulation Resistance Test

- Continuity Test

- Earth Testing

Medium & Low Voltage Switch Gear Panel Board

The primary panel board will be floor-mounted and completely enclosed. The design must incorporate protections for the safety of operators and maintenance personnel.

The general construction must conform to suitable Indian Standard specification.

Cubical type switch board must be fabricated out of sheet steel not < 2.00mm thick.

This steel chamber must be reinforced by angle iron frame work. Unless otherwise permitted, incomer and b1-section panels or sections must be independent.

For multi-story buildings, the horizontal bar should be designed to be visually appealing.

The general arrangement must be authorized before manufacture. All cable entry must pass through gland plates.

Cable entrance plates must be sectionalized. The construction must have cable supports for the cable alloy or rear cable chamber.

Incomer terminations should be adequate for receiving bus bar trunking.

Busbars must be securely mounted on supports made of appropriate insulating materials that meet Indian standards.

The supports must be strong enough to withstand electromechanical stresses from short circuits.

The minimum clearance for open and closed indoor air-insulated busbars functioning at system voltages up to 600 volts is as follows.

| Between | Main Clearance |

| Phase to Earth | 26 mm |

| Phase to Phase | 32 mm |

Distribution

Assemble, align, and install distribution boards according to the supplier’s installation manual and Indian standards.

Test the phase sequence for each incomer and change the connections accordingly.

A mechanical endurance test should be carried out by closing & opening the circuit breaker.

Completion Drawings

Before issuing virtual completion, the contractor must provide five sets of layout drawings to the department officer, illustrating the complete wiring system “As installed” at an allowed scale.

- Drawings should include the following information.

- The length and size of the conduit, inspection & junction boxes.

- Number & size of conductors in each circuit

- Location & rating of sockets and switches for light and power outlets

- Location and information about distribution boards, primary switches, and other specifics

- Detailed wiring and schematic diagrams of the entire electrical system.

- Any instructions, maintenance, or operation manuals for the device.

- Contractors must get approval from the Electrical Inspectorate authority and provide appropriate designs, test certificates, etc.

Electrical Safety Regulations in India for Company/Industries

There are numerous laws under the IS -Indian Electrical Standards & the Indian Electricity Rule 1956.

And if you own a company in India, you must be well aware of the many legal duties linked to electrical safety.

But reading all the guidelines is a time-consuming & tiresome procedure. So, here is a complete list of the most significant Indian electricity rules that you must follow to maintain safe business operations.

Some of the points also describe the legalities involved with the rules.

Let’s explore India’s statutory electrical safety regulations:

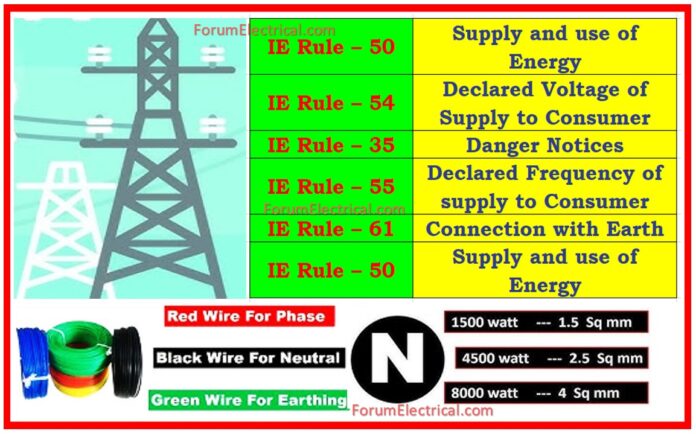

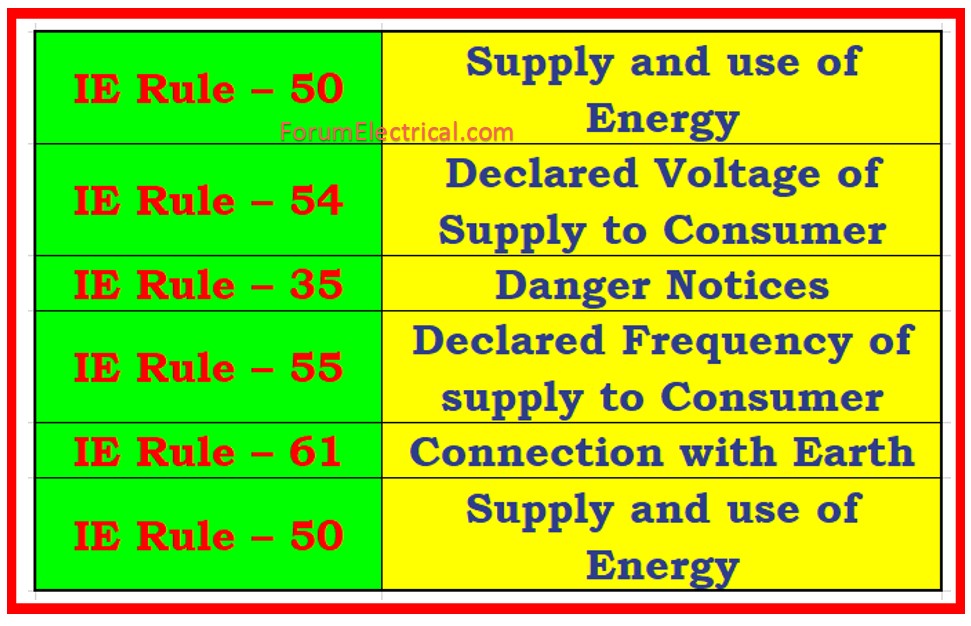

| IE Rules | Description |

| IE Rule – 3 | Authorization |

| IE Rule – 29 | Construction, Installation, Protection, Operation and maintenance of Electrical Supply Lines and Apparatus |

| IE Rule – 30 | Service Lines and apparatus on consumer’s premises |

| IE Rule – 31 | Cut-out on consumer premises |

| IE Rule – 32 | Identification of earthed and earthed neutral conductors and position of switches and cut-out’s therein |

| IE Rule – 33 | Earthed terminal on consumer’s premises |

| IE Rule – 34 | Accessibility of bare conductors |

| IE Rule – 35 | Danger notices |

| IE Rule – 36 | Handling of electric supply lines and apparatus |

| IE Rule – 37 | Supply to vehicles, cranes etc. |

| IE Rule – 38 | Cables for portable or transportable apparatus |

| IE Rule – 41 | Distinction of different circuits |

| IE Rule – 41A | Distinction of the Installations having more than one feed |

| IE Rule – 42 | Accidental charge |

| IE Rule – 43 | Provision applicable to protective equipments |

| IE Rule – 44 | Instruction for restoration of persons suffering from electric shock |

| IE Rule – 44A | Intimation of accidents |

| IE Rule – 45 | Precautions to be adopted by consumers, owners, occupiers, electrical contractors, electrical workmen and suppliers |

| IE Rule – 46 | Periodical Inspection and testing of consumer’s Installation |

| IE Rule – 48 | Precaution against leakage before connection |

| IE Rule – 49 | Leakage on consumer’s premises |

| IE Rule – 50 | Supply and use of energy |

| IE Rule – 54 | Declared voltage of supply to consumer |

| IE Rule – 55 | Declared frequency of supply to consumer |

| IE Rule – 56 | Sealing of meters and cut-outs |

| IE Rule – 60 | Test for resistance of insulation |

| IE Rule – 61 | Connection with earth |

| IE Rule – 64A | Additional Provisions for use of energy at high and extra high voltage |

| IE Rule – 67 | Connection with earth |

| IE Rule – 70 | Condensers |

| IE Rule – 71 | Additional provisions for supply to high voltage luminous tube sign installation |

| IE Rule – 74 | Material and strength |

| IE Rule – 75 | Joints |

| IE Rule – 76 | Maximum stresses-factors of safety |

| IE Rule – 77 | Clearance above ground of lowest the conductor |

| IE Rule – 78 | Clearance between conductors and trolley wires |

| IE Rule – 79 | Clearance from buildings of low and medium voltage lines and service lines |

| IE Rule – 80 | Clearance from buildings of high and extra high voltage lines |

| IE Rule – 81 | Conductors at different voltages on same supports |

| IE Rule – 82A | Transporting and storing of materials near overhead lines |

| IE Rule – 88 | Guarding |

| IE Rule – 89 | Service lines from overhead lines |

| IE Rule – 90 | Earthing (Overhead lines etc.) |

| IE Rule – 91 | Safety and protective devices |

| IE Rule – 92 | Protection against lightning |

| IE Rule – 93 | Unused overhead lines |

Other Rules

- Rejected materials must be removed from the site within 24 hours of written instructions. If the contractor fails to comply, the materials will be removed by a third party at the contractor’s expense.

- Contractors must remove rejected or obstructed materials as soon as feasible and within the prescribed timeframe. Otherwise, the Department may remove them at the contractor’s risk through another agency. The contractor is responsible for all labor costs associated with testing and measuring, including check measures.

- The contractor is responsible for ensuring public safety during electrical operations at their own expense. The contractor’s pricing should include incidental charges.

- Fully accepted agreement rates shall be paid only once all work items have been performed.

- Once a contractor purchases a tender schedule, he is not permitted to return it.

- The work must adhere to the following:

- The code of practice for electrical wiring and fittings in government buildings, The Indian Standard Specification, and

- The Department specification. If the work does not comply with code of practice & Departmental specifications, the contractor will be required to redo the job at no additional cost and pay a penalty as determined by the department.

- Workers must be directly supervised by those with a certificate of competency for the job.

- After completing the work, a layout of the structure should be provided, outlining the location of various primary sub-boards with all fittings, combined with the circuit diagram duly numbered (in the diagram)

- The contractor is responsible for any defects in workmanship or materials provided for two years after job completion.

- There should be 26 lugs for all ground connections.

- The contractor must plan for the transportation of workers and materials to their work site.

- Civil works and patchwork for electrical installations must be completed to the satisfaction of the authorities.

- Each level should have separate distribution boards with the switch controllers for both normal and essential supplies.

- Lighting circuits should have separate conductors to connect regular and essential lighting without affecting other systems. Switching to essential supply ensures minimal lights and avoids trouble for personnel working.

- The control for luminaires in the hall, connected to both regular and vital supplies, must be separate and independent of each system.

- To link points to vital supplies, a separate conduit system must be installed, which includes the circuit main for any system.

- During execution, the positions for D. B’s & switch controls for critical supplies will be determined, as the circuit conduit way must be ended.

- The tenderer must provide a compliance report detailing installation testing, including IR values and fitness, prior to Energisation as per IE standards. After Energisation, the tenderer is fully responsible for any defects.

- The tenderer is responsible for ensuring that the site is taken over after issuing a work order or signing an agreement, and that work begins promptly. Failure to comply will result in penalties as outlined in the agreement.

- The tenderer must keep test equipment on site at their own expense for convenience of inspecting officers until the job is finished.

- The contractor must carry out the work according to the Electricity Board’s specification.

- The contractor must purchase components from recognized and registered vendors with the Electricity Board.

- The contractor should get a Q.C. certificate for materials from the Electricity Board.