Lockout is the recommended method to disconnect machinery or equipment from power sources. All equipment must be shut down (or) marked to prevent accidental (or) inadvertent operation that could harm personnel.

- Documenting Equipment & Employee Details

- Procedure Awareness & Training

- Inspection of LockOut/TagOut Devices

- Step-by-Step Review of the Lockout/Tagout Procedure

- Step 1: Before Starting Equipment Service

- Step 2: Shutting Down the Equipment

- Step 3: Isolating Machinery or Equipment

- Step 4: Attach the Lock & Tag

- Step 5: Controlling Stored Energy

- Step 6: Verifying the Zero Energy State

- Final Review and Documentation

- Log Book and Document Retention

- Checklist/Form

Utilizing a complete LockOut/TagOut (LOTO) Inspection Form is an effective way to guarantee workplace safety.

Compliance can be simplified, equipment isolation procedures can be tracked, and accidents can be avoided with the use of an easy-to-use template that was built for OSHA standards. Perfect for the administration of safety in the electrical, mechanical, & industrial sectors.

The LockOut/TagOut (LOTO) procedure is an important safety procedure that prevents the inadvertent release of dangerous energy during equipment maintenance & service.

The following post explains over the key components of the LOTO inspection form, which employers can use to document the inspection of a written lockout (or) tagout procedure.

Documenting Equipment & Employee Details

The form starts by identifying the department & the specific equipment under inspection, including its type and serial number. It provides areas for noting the

- Inspection Date,

- Equipment Location, and

- Inspector’s Name.

This section records the responsible persons and the equipment subjected to the LOTO procedure.

The form then lists the names of approved personnel who have received training on the procedure.

It is essential to determine whether these individuals have received proper training, as indicated by a “Yes” or “No” response.

A person who is qualified based on their knowledge, experience, and training to organize and perform the work; who is familiar with the rules and regulations that apply to the work; and who is aware of any possible or actual threats to health and safety in the workplace.

Employers: Use this form to document the inspection of a written lockout (or) tagout procedure.

- Identify the place and task where Lockout/Tagout procedures are being used.

- When it is safe to interfere with the employees, introduce yourself and explain the purpose of the inspection.

- Fill out the inspection form with the names of interviewed personnel and indicate if they are permitted or affected by the Lockout/Tagout procedures.

- Ask staff if they have received Lockout/Tagout training. If personnel have not been trained, they should suspend their operations and alert Department Management.

- Check the relevant box for personnel who have been trained, and verify the date of training after inspection.

- Determine whether energy-control methods are being followed. Use the corresponding checklist to document your findings.

- If energy control measures are not followed, stop all activity and alert Department Management.

- Examine the Lockout / Tagout equipment in operation and ensure that it satisfies the basic requirements of the procedure.

- Print your name, then sign & date the inspection form. Include the day that you were instructed in lockout/tagout procedures.

Procedure Awareness & Training

An important component is ensuring that impacted staff have been trained to recognize the method and told not to tamper with lockout/tagout devices (or) attempt to re-energize the equipment.

The form’s primary objective is to assess the efficacy of the LOTO procedure. It concerns if the procedure is adequate in protecting employees. If any problems are detected, the form allows you to identify them and provide solutions.

This proactive phase ensures worker safety by correcting any holes in the method.

Inspection of LockOut/TagOut Devices

It also involves documentation of the employee’s name, date, and a description of the action associated with the lockout procedure.

This provides a detailed record of LOTO equipment usage, which helps to ensure system accountability.

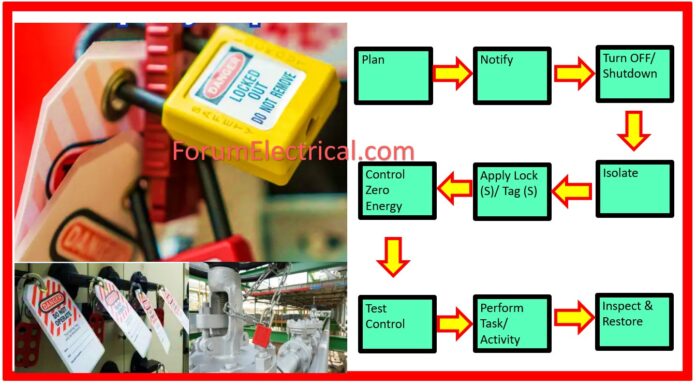

Step-by-Step Review of the Lockout/Tagout Procedure

Step 1: Before Starting Equipment Service

The form generates a detailed checklist for ensuring the safety of all energy sources. It confirms that the type and quantity of energy sources have been determined, and that the associated risks have been mitigated.

The steps for regulating energy must be recognized, & impacted staff must be notified when equipment will be turned off for maintenance.

Step 2: Shutting Down the Equipment

It is essential to adhere to both corporate safety procedures and manufacturer recommendations during the shutdown period. The form asks if certain protocols have been followed.

Step 3: Isolating Machinery or Equipment

Isolation consists of turning off main breakers, stopping valves, & disconnecting process lines. The form requires that these steps be completed before proceeding.

Step 4: Attach the Lock & Tag

Step 5: Controlling Stored Energy

The form inquires whether stored energy, such as electrical capacitance, has been entirely bled, and whether hydraulic lines, tanks, and other possible energy sources have been vented or drained.

Step 6: Verifying the Zero Energy State

Before maintenance starts, all energy states must be zero. This section of the form contains checks to confirm that the equipment is completely de-energized and that there are no dangerous chemicals or pressures in the system.

Final Review and Documentation

If all steps are completed successfully, the form validates successful execution of the LOTO procedure. The employee must be able to describe the process, & the inspector must certify that energy control measures are followed appropriately. Any variations from the protocol must be documented, with corrective comments provided.

Log Book and Document Retention

This log book is essential for documenting LOTO activities and maintaining compliance with safety requirements.

Finally, the employee performing the inspection must sign the paperwork, including their ID number and date. The form is saved in the Safety and Health Management System for later auditing and reference.

Documenting each stage of the process fosters responsibility and gives a clear record of adherence to safety requirements.

Regular usage of this form promotes a safer working environment and aids in regulatory compliance.