What are LOTO Color Codes?

- What are LOTO Color Codes?

- How to read LOTO Color Codes?

- What does LOTO colors mean?

- Red – Personal Lockout (Primary Lock)

- Yellow – Group Lockout

- Blue – Authorized Personnel Lock

- Green – Equipment Lock (Departmental Lock)

- Orange – Testing or Commissioning Lock

- Fluorescent Orange Lock

- Purple – Contractor Lock

- Purpose of Color LOTO Tags

- What is the Color Code for Locks?

Lockout/tagout (LOTO) devices are an important OSHA-mandated safety precaution when repairing or maintaining hazardous equipment.

One (or) more LOTO devices are get attached to the instrument will indicate that it has been de-energized using a prescribed technique, making it safe to work on or around.

They will also prohibit anyone from re-energizing the equipment until the staff with the keys have completed their tasks and removed the lockout devices.

How to read LOTO Color Codes?

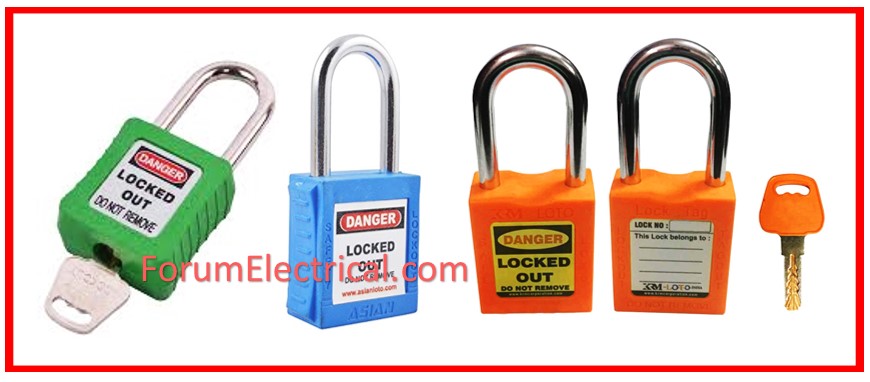

These may be red or orange, but at other facilities, they may also be blue, green, or another hue.

The simple fact that they are so noticeable indicates that they are operating as planned.

Their exceptional colors act as a visual alert that something significant is happening.

What does LOTO colors mean?

Color codes vary by brand & area, but generally follow certain industry standards:

Red – Personal Lockout (Primary Lock)

Individuals who do maintenance or service use this product. This indicates that a worker has locked out the equipment for their personal safety.

Only the person who installed the lock can remove it.

It is for this reason why red is by probably the most popular color for LOTO devices, and the term “DANGER” should be included with red letters (or) outline.

Additionally, organizations are free to build their very own one-of-a-kind color-coding schemes.

Yellow – Group Lockout

Yellow – Group Lockout are used for lockout procedures involving numerous workers.

This lock may be controlled by a group leader (or) a supervisor.

Blue – Authorized Personnel Lock

Used when equipment requires servicing yet does not necessitate complete separation.

Green – Equipment Lock (Departmental Lock)

Green locks are used to isolate equipment for extended durations, such as shutdowns or maintenance.

Typically managed by a certain department.

Orange – Testing or Commissioning Lock

Orange locks are used during equipment testing or troubleshooting.

This indicates that transient energization may occur.

Fluorescent Orange Lock

They indicate that anyone working nearby must take appropriate precautions in response to the hazards.

A neon orange sticker reads “Biological Hazard” and acts as a warning sign that the location is a bio hazard that personnel must be aware of.

Purple – Contractor Lock

SPurple lock are used by external contractors on-site.

Helps to distinguish between firm employees & third-party workers.

It uses the black/white “Out of Service” or “Do Not Operate” lock on retired or unsafe equipment.

Not for personal safety, but to identify unusable machinery.

Purpose of Color LOTO Tags

Identification

This guarantees that workers can readily identify which machinery remains operational and which has been turned off & is secure to work on.

Communication

They also provide other essential details such as the current condition of equipment.

This helps to avoid unintentionally energization & provides detailed guidance to all staff in the neighborhood.

Compliance

Accountability

This enables accountability and traceability throughout the lockout process.

What is the Color Code for Locks?

What are the OSHA colors for LOTO?

OSHA doesn’t require accurate color codes for the LOTO, however it suggests the following:

- Orange: Warning Signal

- Yellow: Safety Caution Signal

- Red: Danger Signal.