Overview

This Method Statement goes into extensive detail on all the scope of work required in transformer oil filtration and storage tank oil filtration.

Objective

This method statement is intended to specifically understand the task and step-by-step procedures of the execution of the job along with safety measures, which are required to avoid any form of injuries or accidents to personal (or) any damage associated with equipment or property.

This also notes the list of required tools.

Scope of Work

- Oil Filling & filtration of storage tank

- Oil Filling & filtration of Main transformer

Responsibility

- Transformer Engineer

- Filtration Operator

- Safety Engineer

- Skilled Technician

Tools Required

Before use, check tools and machinery to make sure correct storage along with usage.

In order to carry out the necessary undertaking, the subsequent sets of equipment will be carried out.

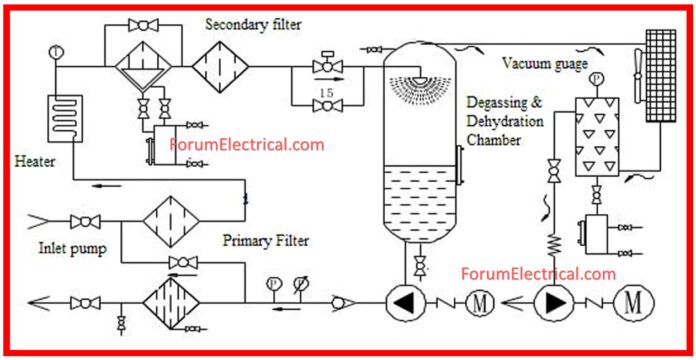

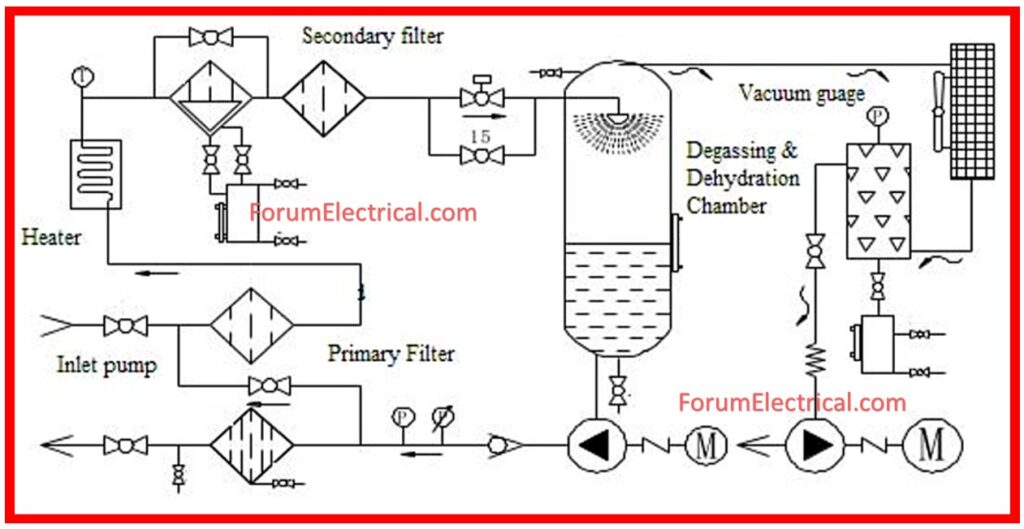

- Oil filtration machine

- Vacuum machine

- Storage tank

- BDV kit

- Proper hoses

- Standard hand tools

Safety

- Safety toolbox meetings scheduled before work; tools of safety scheduled and attended by every employee assigned to do task.

- To be done is a random analysis.

- Safety staff and assigned responsible person will make sure that all above is followed and any other statutory needs are finished before any work gets started.

PPE Requirements

Staff members or laborers should utilize the minimum of the following PPE.

- Safety shoe

- Dust mask

- Safety goggles

- Safety harness

- Hand gloves

- Cover All with High visibilities vest

Procedure

Oil Filling & Filtration of Storage Tank

- Make sure the oil storage tank is standard-compliantly fitted with breather and cleaned.

- To stop the spills, cover the Transformer Oil Pallet Storage Area with polythene cover or Tarpaulin.

- Using fork lift and trailer, transformer oil pallets will be moved from storage yard to close transformer location.

- Oil filtering units will help to move transformer oil from the oil drums to the oil storage tanks.

- Manufacturer recommended transformer oil filtration machine will filter storage tank oil.

- Circulate oil at least 4 cycles or until required parameters to reach of BDV (>60 KV).

- Oil BDV test kit will be used for transformer oil (BDV) break down voltage test; manufacturing standard findings will be confirmed.

- Stop filter machine according to the process and unplug all hoses from the transformer after obtaining desired values (>60 KV).

- Appropriate barricaded work will be done.

Oil Filtration Working In Transformer Main Tank

The filtration of transformer oil is carried out with the purpose of enhancing the dielectric strength, reducing the water content, and eliminating sludge and gasses.

Transformer Oil Filling from Tank under Vacuum

- Following the change in the new transformer. Transformer leak test will be carried out according to manufacturing norms.

- Between the diesel generator & transformer vacuum machine, the cable connections will be done.

- Vacuum machine hose will be attached from the vacuum machine to transformer & the vacuuming operation will be carried out according to transformer manufacturer specification.

- Recorded will be the Transformer Vacuum Value. Once Below -760 mm/Hg, the transformer vacuum keeps running while oil is being filled from the storage tank according OEM standard.

- Connected across transformer oil filtration valves & the oil filtration unit are the oil hoses.

- Transformer new oil will be moved from tank of storage to transformer.

- N2 gas filling will help to break the vacuum.

- Some concern air release bolts (Radiators, bushings,) will release air locks.

Transformer Main Tank Oil Filtration

- To ensure filtered hot oil will arrive from the top of transformer for correct mixing, connect filter machine suction line at bottom of transformer & discharge at conservator drain valve.

- Turn on the electricity for the filter machine & check any of the reverse phase alarms. Should any warning alter 1 phase notation at MCB’s side,

- Adjust the oil temperature across 65 & 70°C.

- Start the filter machine according to its protocol.

- Open transformer bottom valve & filtration suction / intake valve after obtaining vacuum in degassing chamber.

- Before connecting to conservator drain valve, remove small oil from the filter machine discharge hose.

- At least four cycles or until required parameters to reach of BDV (>60 KV), circulate oil without any interruptions.

- Watch the conservator’s oil level constantly. Turn off the machine if any unexpected oil level drops.

- After four cycles, run the oil BDV. The sample has to be taken at the transformer bottom sample valve.

- Track test values and transformer top oil temperature at every stage.

- Once desirable values (>60 KV) have been reached, stop the filter machine as advised and cut all hoses from transformer.

- If the conservator has an oil level, check it; else, go to the graph showing oil against temperature graph for topping up.

- After 24 hours, release or expel air from the air bag and inspect all locations.

- Instinctively as the filtration is finished, breathers should be placed.

- Check oil BDV once more 24 hours after the work is done.

- Organize everything, clean the workspace, clear the permit, then let the customer know accordingly.

Transformer Oil BDV Test

- The highest voltage tolerate capacity of oil, without breakdown, is the BDV, or dielectric strength.

- Transformer functioning free from problems depends much on the BDV test of the transformer oil.

- Thus, to guarantee the healthiness of transformer oil BDV, periodic testing of it is very necessary.

- The sample is removed from the transformer tank, and BDV tester checks oil BDV.

- Fundamentally a high voltage unit, the BDV test kit allows one to control the voltage between 0 and 100KV.

- Two electrodes of the BDV tester are separated by 2.5 mm.

Standards for BDV Test

Standards for BDV testing include IEC 60156, which employs acceptance values from IEC 60296 & IEC 60422.

- IEC 60296: Fluids for electro-technical uses – Unused mineral insulating oils for transformers & switchgear. This standard only covers new, unused oil as obtained from the supplier, which must comply with a dielectric breakdown voltage of 30 kV (or) greater, ascertained using the IEC 60156 test technique. Laboratory vacuum filtered oil should have a minimum dielectric breakdown voltage of 70 kV.

- IEC 60422: Supervisor and maintenance handbook on mineral insulating oils in the electrical equipment. This standard specifies suitable dielectric breakdown values for in-service and new oil (after filling but before energizing).

Transformer Oil BDV Testing Procedure

- The Oil sampling point should be suitably clean.

- Transformer oil allows you to clean oil sampling bottles three to four times.

- In a BDV tester glass pot or Sampling bottle, gather the 300–400 ml sample of transformer oil free of air bubbles (or) dust particles from bottom valve of transformer (or) Storage tank.

- Next place oil sample in machine.

- Up to with stand level, the automatic BDV tester will raise the voltage at 2 KV/Sec and let one view the oil sample via a glass window.

- Increase the voltage and continuously view the oil sample via an inspection window.

- Automatically BDV tester shall record the KV where sparking is seen in the oil. The breakdown voltage (BDV) of oil determines the observed voltage for sparking.

- Six times repeat steps No: 4, 5, 6 for the same sample and record the breakdown KV in every case.

- Get the average of BDV values recorded in six values.

- Transformer oil is in good condition if the average value of oil BDV is over 60 KV.

Reference

- Machine drawing and manual

- Calibration certificates

- Approved Method statement & Scope of work

- Project safety plan

- Manufacturer manual

- Project Quality Plan