The UPS checklist acts as a proactive tool, allowing organizations to get ahead of any faults that may develop during power outages. The comprehensive check includes vital components such as the

- Battery backup system,

- Cooling mechanisms,

- Cabling, and

- General equipment condition.

Following this checklist on a regular basis is more than simply a maintenance routine; it is a proactive way to protect your organization from unexpected power outages.

Implementing a comprehensive UPS maintenance checklist ensures that your UPS system is ready to go when needed the most.

Every responsibility on the checklist, from testing input & output voltage to evaluating battery terminals and assuring cooling system functionality, is essential to maintaining optimal UPS operation.

As technology improves, companies want innovative ways to streamline processes.

By applying technology, can easily manage operations while maintaining compliance with the UPS checklist from any location and at any time.

Testing UPS Function

- To verify that your UPS (Uninterruptible Power Supply) is working properly, conduct a comprehensive assessment of its condition.

- Look for any physical damage, odd sounds (or) signs of wear & tear that may signal a fault.

- Regularly monitoring the device assists in the quick identification of faults, ensuring consistent performance during power interruptions.

Indication Check

- Check the indicator lights is ON in UPS.

- These lights provide essential data about the unit’s functionality, battery health, & load status.

- Ensure that the lights relating to regular functioning & battery condition are illuminated according to the manufacturer’s instructions.

- If any warning (or) error lights come on, refer to the user handbook for troubleshooting instructions.

Unit Wiring

- A UPS cannot function properly without proper wiring. Check every connection to ensure that they are secure & properly setup.

- This includes the power input, output to connected devices, & any communication lines, if the UPS is network capable.

- Incorrect cabling might cause the UPS and its attached devices to malfunction or possibly be damaged.

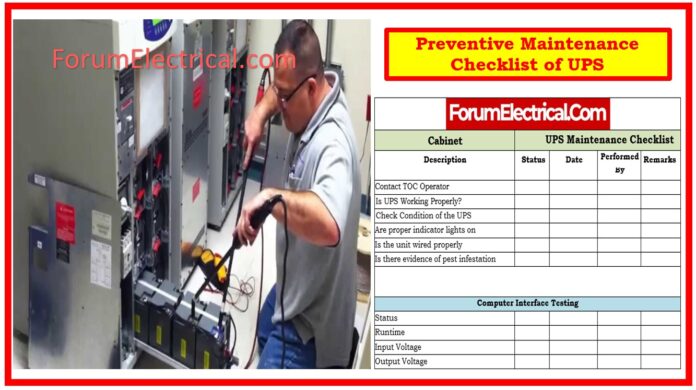

Computer Interface Testing

Several important factors were analyzed throughout computer interface testing to provide the best possible performance and stability.

These characteristics comprised runtime, input voltage, output voltage, battery capacity %, battery voltage, and load power percentage, all represented in watts.

Each of these components are essential for determining the overall health & functionality of the system.

Diagnostics

The diagnostics part included a full self-test & calibration result analysis.

The self-test was run to check for any imminent issues or problems with the system, verifying that all components were working properly.

The calibration data were checked to ensure that all readings were correct and within the stated tolerances, validating the system’s precision.

Configuration Settings

Configuration settings were thoroughly reviewed to ensure alignment with operational requirements.

The line configuration & output voltage were verified to meet the minimum standards.

Furthermore, the high and low transfer points were tested to ensure that they were properly configured to avoid any potential overvoltage (or) undervoltage conditions.

General information, such as the latest battery replacement date, was captured, allowing for a clear maintenance history & future service planning.

Maintenance Activities for an UPS system

The maintenance activities for an UPS system are designed to ensure its maximum functioning and longevity.

- Every two months, a number of checks & inspections are performed.

- These include visually assessing for liquid contamination in batteries and capacitors, inspecting electrical circuits and control cards, validating output frequency, visually inspecting grounding, & ensuring that battery interconnections and cables are tight.

- Testing is also performed on UPS transfer switches, circuit breakers, & maintenance bypasses. The equipment enclosures are cleaned & vacuumed, & the alarms and LEDs are checked for any problems.

- Voltage and current values are taken for both input & output, & the distribution of loads per phase is evaluated.

- An essential offline load test is performed to ensure the UPS system’s functionality.

- These checks and testing are done every four to six months to ensure the system’s reliability.

- Moreover, HVAC equipment is inspected to ensure that temperature and humidity control are functioning properly.

By following this maintenance schedule, the UPS system can continually provide uninterrupted power supply.