- Pre-Requirements of MV Switchgear

- Safety Precautions

- Test Equipment

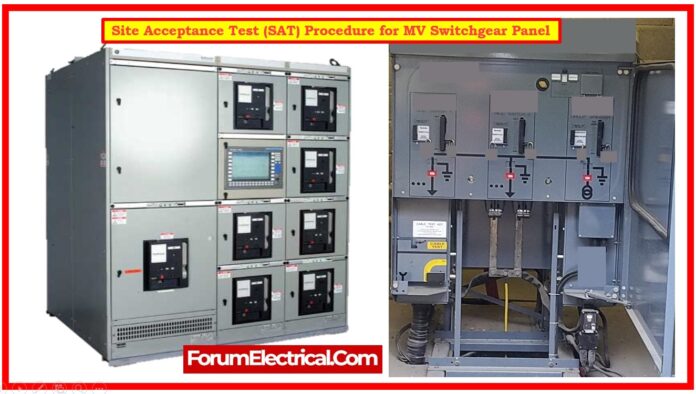

- General Information

- Mechanical Check and Visual Inspection

- Test Procedure

- Step-1: CT and VTs Test

- Step-2: Circuit Breakers Test

- Step-3: Testing of Protection Relays & Digital Meters

- Step-4: Busbar CRM and Primary Injection Test

- Step-5: Functional Check

- Step-6: Hi-pot Test

The switchgear must pass the site acceptance tests (SAT), which ensure that it operates as intended before powering up, following switchgear erection, installation, control wiring assembly, and before connecting any cables from the plant.

The IEC standards 60694 & 62271-200 are the source of SATs.

Although the tested functions may differ throughout switchgear configurations, the SAT remains essentially the same for all configurations.

Each switchgear configuration should have its various functions tested because some, like the synchronization check function across the incoming cubicles to synchronize the coupling of 2 different power sections, and others, have special protection functions for the outgoing cubicles.

Pre-Requirements of MV Switchgear

- Installed metal clad switchgear, including CBs, and completed inter-panel wiring.

- All tools for the earth switch, rack-in/out, spring charge, and panel keys should be provided.

- Provide AC/DC electricity as per authorized scheme.

- All approved designs must be available at the test location.

- Ensure proper illumination and safety measures.

Safety Precautions

Follow up of all Safety Procedure and PPM Guidelines.

Test Equipment

- Insulation tester (Megger) 5 kV Micro-ohmmeter

- Analyzers for CB, CT, and VT

- Secondary Injection Test Kit

- Primary Injection Test Kit

- High Voltage Tester

- 0-75 kV AC Multimeter

General Information

The Metal Clad Switchgear will be inspected for recording ratings, serial numbers, and so on. The test will be performed on each column of the MV Switchgear.

Mechanical Check and Visual Inspection

Mechanical and visual inspections must be performed to confirm that the metal covered switchgear is free of physical damage and is fitted according to the plans. Tightness, grounding, and phase indications will also be evaluated.

1. Inspect the physical, electrical, and mechanical conditions.

3. Check for correct anchorage, clearances, physical damage, & alignment.

4. Check that current & potential transformer ratios match the drawings.

5. Check all bus connections for high resistance.

6. Use a calibrated torque wrench to check the tightness of bolted bus joints.

7. Test electrical & mechanical interlock systems to ensure appropriate operation and sequencing.

8. Check all mechanical indicators for correct operation.

Test Procedure

Step-1: CT and VTs Test

Current Transformers Checks

- Ct Polarity Checks

- Insulation Test

- Ratio Test

- Ct Winding Resistance

- Knee Point Voltage

Voltage Transformer Checks

- Insulation Tests

- VT Resistance Measurements

- VT Ratio Check

Testing of CT and VT

Insulation resistance must be done

- Primary to Earth (5 kV)

- Primary to Secondary (2.5 kV)

- Secondary to Earth (1 kV)

- Secondary to Secondary Cores (1 kV)

A CT analyzer is required to be used in order to determine the ratio, winding resistance, and Knee point. Additionally, the date must be recorded & compared with the FAT.

In order to determine the VT ratio and winding resistance, the analyzer must be utilized, and the results must be compared with the FAT.

Step-2: Circuit Breakers Test

Circuit breaker Checks

- IR & contact resistance measurements.

- CB Mechanical Operating Test.

Contact Resistance Measurements

- Contact Resistance are measured.

- Closing all of the (CBS)

- The micro ohmmeter test is carried out with a current of 100 ADC.

- Establish a connection between the test set and the initial phase of CB.

- Make a recording of the reading.

- Repeat the process for each and every CB phase.

Mechanical Operating (Timing) Testing of CB

- Establish a connection between the test set and the CB.

- Carry out the operation listed below at the DCV that is rated.

- Close (C)

- Open (O)

- Close – Open (C – O)

- Record the correct readings for each of these conditions.

Step-3: Testing of Protection Relays & Digital Meters

- Test Protection Relays & Meters Using Secondary Injection.

- Overcurrent and Earth Fault Tests

- Under-Voltage Tests

- Trip Circuit Supervision Relay

- LEDs and Contacts

- Ammeter and Voltmeter Checks

- Check the KWH Meter.

Over Current Relay Test

- Overcurrent Pick-up

- Set the testing relay for overcurrent.

- Connect the current test set to the relay current terminals.

- Gradually increase the current till the pick-up indicator works.

- Record operational current.

Operating Time Verification

- Set the testing relay for overcurrent.

- Choose the time over current curve for the relay.

- Attach the current test set to the relay current terminals.

- Connect timer to relay tripping contact.

- Test the relay by injecting current and monitoring its functioning time.

- Record operating time.

Under Voltage Verification

- Set the relay for testing.

- Connect the voltage test set to the relay terminals.

- Connect the timer to relay tripping contact.

- Apply the operating voltage to the relay and gradually reduce it until it picks up.

- Record the pick-up voltage.

Delay Time Verification

To test the relay, follow these steps:

- Set the operating time

- Connect the voltage test set to the relay terminals

- Connect the timer to relay tripping contact.

- Inject the testing voltage and observe the relay’s operation

- Record the operating time.

Earth Fault Relay

- Set the relay for testing.

- Connect the voltage test set to the relay terminals.

- Connect the timer to relay tripping contact.

- Apply the operating voltage to the relay and gradually increase it until it picks up.

- Record the pick-up voltage.

Delay Time Verification

To test the relay, follow these steps:

- Set the operating time

- Connect the voltage test set to the relay terminals

- Connect the timer to relay tripping contact

- Apply the testing voltage and observe the relay’s operation

- Record the operating time.

Testing Metering Accuracy using Secondary Injection Kit

Ammeter Check

- Connect the present test set to the ammeter terminals.

- Check for neutral current by injecting 50, 75, and 100% of the ammeter’s full-scale current into distinct phases.

- Record ammeter readings.

- Inject 100% of the typical current.

- Record the relevant ammeter reading.

Voltmeter Check

- Attach the voltage test set to the voltmeter terminals.

- Use 100% of the voltmeter’s full scale voltage.

- Record the voltmeter measurements.

KWH Meter Check

- Connect the present test set terminals to KWH meter’s terminals.

- Attach voltage test set terminals to KWH meter’s terminals.

- Use all of the rated power.

- Record the KWH meter values.

Step-4: Busbar CRM and Primary Injection Test

Contact Resistance (CRM) Check of Primary Circuits (Busbar & Terminals)

- After assembly, the switchgear’s principal circuits are examined for tightness and electrical contact/mating at joints to prevent heating caused by high resistance or male-female contacts of withdrawable breakers.

- The micro ohmmeter test uses a current of 100 ADC.

Primary Injection Tests

- Attach the primary injection test set terminals to CT’s primary terminals.

- Inject 100 amps of current between two feeders each phase.

- Record secondary readings for each core and phase.

- Check Contact Resistance and Conduct Primary Injection test.

Step-5: Functional Check

- Conduct an AC high-pot test on-site.

- The test will measure leakage current at a test voltage of 24 kV for 60 seconds.

- The CB will be opened once and the VT will be racked out.

- All CBs will be tested once and VT will be racked out.

- The test will be performed with all CBs closed & VT racked in with the rated voltage.

Step-6: Hi-pot Test

The function check will be performed in accordance with the interface logic diagram.