Megger testing is a crucial check conducted on high-tension (HT) transformers for measuring the IR and PI, fundamental parameters in terms of the transformer’s health and running condition.

The intention of this test is to confirm that the transformer insulation system is accurate and not prone to developing numerous types of faults that could lead to system breakdown.

All through these steps, safety should be put into considerations at all times.

The procedure is based on IEC 60076 (Power Transformers) insulation resistance testing standards.

They require the personnel to wear correct personal protective gear and acquire a proper safe working permit and limit entry into the testing zone.

It can be carried out in varying steps in practice but in this case the four basic steps in the procedure include isolating and discharging the transformer, checking the function of the megger, measuring the insulation resistance, and polarization index.

Upon the completion of the tests, the transformer is then checked and normal power supply is again brought into the transformer in the most secure way.

It ensures dependency of the transformer and safe working conditions for the personnel.

Purpose

The purpose of this test is to assess the insulation resistance and polarization index of an HT transformer, as well as its overall health.

Responsibility

- Electrical Incharge

Maintenance Documentation

The manufacturer’s manuals must be updated, available on the platform, and reviewed by all personnel who will do meggering on the equipment.

Safety Precautions

Evaluate weather conditions when operating offshore.

Personal safety (PPE) equipment is essential.

Before starting any meggering work, conduct pre-job planning & risk assessments.

Obtain a safe work & isolation permit before starting the job.

Clear and close the work area.

During work, ensure that the restricted area is marked with warning signs (LOTO) & tape.

HT Transformer Meggering Procedure

- The transformer should be isolated by turning off the LT ACB in accordance with the normal procedure.

- Make certain that the additional load is being successfully taken on by the other transformer or transformers.

- In order to rack out the VCB, you must first turn off the HT VCB, then remove its control plug.

- Take off the cover that is associated with the HT (High Tension) terminals of the transformer.

- An earthing rod should be used in each of the three phases to discharge any static charges that have been collected.

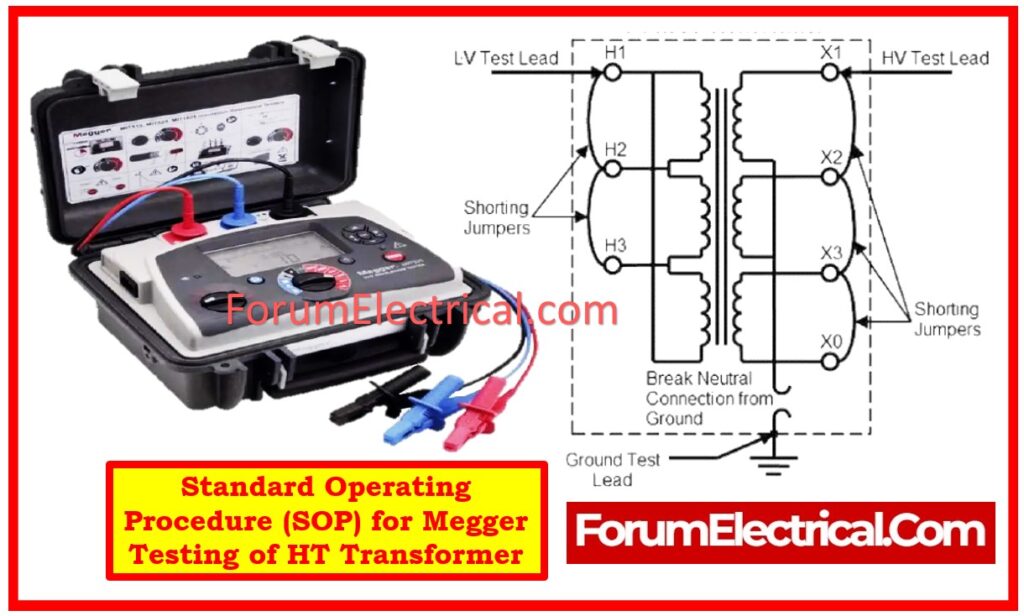

- Carry out a functional check of the megger in accordance with the following:

- Check that the Megger has a sufficient amount of power to complete the work.

- Ensure that both probes are open while operating the HT megger at the voltage that has been specified. Infinity is the correct reading to perform.

- In order to operate the megger, both of the leads need to be shorted. It is best to take a reading of zero (short).

- Attach one of the leads to a place on the earth, and the other lead to a different position on the frame. The reading must be zero ((short)).

- Make use of a multimeter to determine the resistance of the transformer’s HT winding between each of the three phases.

- In order to connect the Megger’s earth lead to the earth, you must first connect the line lead to one phase of the transformer. Put the Megger into operation.

- It is essential that the Megger be switched to the appropriate voltage. The transformer’s HT windings should be meggered, and the Insulation Resistance readings should be recorded for both one minute and ten minutes.

- In order to determine the value of the PI, divide the value for ten minutes by the value for one minute.

- Check to see if it falls within the acceptable range, and if it does not, take the appropriate measures.

- Check for any indications of damage on the HT transformer’s outside, particularly the wires. Additionally, check the terminals to ensure that they are not loose.

- Ensure that the grounding cable is attached securely to the base of the equipment mounting surface. This responsibility comes to grounding cables.

- Check that the terminal box does not contain any tools remaining inside of it. Cover the terminal with the cover.

- Insert control plug and rack the HT VCB into the circuit. HT VCB should be closed.

- In accordance with the regular operating practice, load the transformer by shutting the LT ACB.

- Please make a note of the IR and PI values in the documentation record (register).