1). What are the primary circuits in thermal power plant?

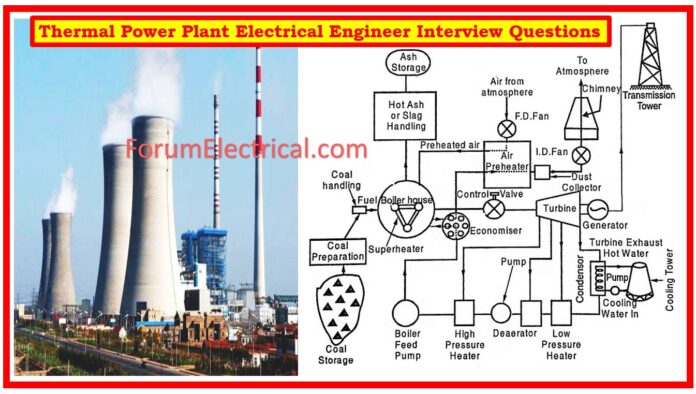

The thermal power plant comprises of 4 primary circuits, which are:

- Feed water & steam flow circuit

- Coal & ash circuit

- Air & gas circuit

- Cooling water circuit

2). What cycle does a steam power plant operate on?

Steam power plants use the Rankine Cycle.

3). What is the thermal efficiency of a steam-powered plant?

The thermal efficiency of a steam power plant is described as the heat equivalent of the mechanical energy delivered to the turbine shaft divided by the heat of combustion.

Generally, the thermal efficiency of steam power plant will be between 30 & 35%.

4). What is the overall efficiency of thermal (or) steam power plants?

The overall efficiency of system is expressed as the heat equivalent of electrical production divided by the heat of combustion.

Generally the steam plant’s overall efficiency will always be less than its thermal efficiency, which will be around 29-33%.

The overall efficiency of a steam plant is calculated by multiplying the thermal efficiency of plant by the efficiency of the generator (electrical efficiency).

5). Why is the thermal efficiency of steam power plant so low?

In a steam power station, more than half of the total heat of combustion is lost as heat rejected to the condenser, and this loss is unavoidable because heat energy cannot be transformed into mechanical energy without a temperature decrease.

Steam in the condenser is at its lowest temperature. This is the reason the thermal efficiency of power plant is so poor.

6). What factors determine the efficiency (thermal) of the steam plant?

The efficiency of a thermal plant depends on three factors:

1). The pressure of steam entering the turbine

2). Temperature of steam entering turbine.

3). Pressure in the condenser

Thermal efficiency rises with the temperature & pressure of the steam entering the turbine.

For this reason, high temperatures and pressures are used. Thermal efficiency is efficiently increased by lowering the pressure in the condenser, so it is kept as low as feasible.

Thermal efficiency is also increased by reheating the steam across turbine stages.

7). Why do thermal power plants generally situated next to lakes or rivers?

Because they need a lot of water to accomplish their requirements, thermal power plants are located near rivers or lakes. Plants that produce steam need water.

- Steam in the boiler

- For cooling applications, such condensers

- As a carrying medium, for example, when disposing of ash.

- For the purpose of drinking

8). What does a steam power plant’s deaerator do?

Water that has dissolved gases, such as carbon dioxide and oxygen, reacts with metal to generate iron oxide, which is what causes the corrosion.

As the temperature rises, the solubility of gases in water drops and reaches zero at the boiling or saturation point.

By raising the temperature of the condensate (feed water), the deaerator aims to lower the amount of dissolved oxygen in the mixture.

By using the bled steam from the turbine to heat the feed water to saturation temperature, these gases are eliminated in the deaerator.

9). Why is the steam power plant required to include cooling towers?

Towers for cooling recirculate the cooled water back into the condenser after cooling the heated water that was released from it.

The cooling towers have two different types of cooling mechanisms:

- Wet Type Cooling Tower and

- Dry Type Cooling Tower.

Wet Type Cooling Tower

Warm water from the condenser is forced to spray on horizontal bars or slats in wet cooling towers, and air is forced through the bottom of the tower as the water splashes down from one slat to the next due to gravity, mixing the air and water and rejecting heat into the atmosphere.

Dry Type Cooling Tower

When there is a shortage of cooling water, dry type towers are used. In a dry type, cooled air is passed across finned tubes that allow warm water from condensate to flow through them. Water cools by rejecting heat to the atmosphere.

10). Why are heaters for feed water used?

- Regenerative In steam power plants,

- Feed water heaters

are used to increase cycle efficiency.

Additionally, it lowers the steam flow to condenser and increases the steam flow rate. Prior to the feed water entering the economizer, they increase its temperature.

11).Which electric systems are the main ones in a thermal power plant?

The thermal power plant’s primary electrical components include

- Turbine Generator

- Exciter System

- Generator Protection System

- Generator Transformer

- HT/LT switch gear

- Electrical Switch-yard

12). Which generator protection mechanisms are used in thermal power plants?

- Windings faults,

- Over speed protection,

- Loss of excitation protection,

- Overheating of windings (or) bearings,

- Overload protection, and

- Motoring operation protection unintentional ignition,

- Protection against single-phase or unbalanced current,

- Protection against out-of-step operations,

- Protection against sub-synchronous oscillations, and

- Protection against earth faults.

13). In a thermal power plant, how is the generator transformer cooled?

The generator transformer’s MVA power rating will match that of the alternator.

Therefore, when the generator transformer is operating, a lot of heat will be produced.

The generator transformer uses the Oil Forced Air Forced (OFAF) method of cooling.

14). Which circuit breakers are used in thermal power plants and what types are each of them?

- 415/220V vacuum circuit breakers (or) air break circuit breakers are used for low voltage operation.

- SF6 circuit breakers are used for voltage ratings of 6.6 kV and higher.

15). Which type of cooling is accessible in the power plant for the generator?

Due of hydrogen’s superior heat-carrying capacity, large-scale generators use hydrogen gas cooling.

The generator’s core and rotors are cooled by hydrogen. The alternator’s stator has access to water cooling.

16). What are the various auxiliary systems in a thermal power plant?

- Coal handling and storage,

- Coal pulverization,

- Water treatment plant,

- Steam boiler,

- Drought systems,

- Ash handling systems,

- Steam turbine,

- Circulation water system,

- Electrical systems,

- Control and instrumentation,

- Pollution control equipment, and

- Fire protection system.

17). What is the function of pulverizers?

Pulverizers are used for two purposes:

- Drying coal and

- Grinding coal.

They crush coal to a size of 74 microns.

18). What are the different types of pulverizers?

There are various types of pulverizers:

- Ball Tube Mill

- Ring Roll Mill

- Hammer mill.

- Attrition mill.

19). What are the various types of steam boilers utilized in thermal power stations?

There are various types of boilers utilized in thermal power plants.

- Fire tube boiler.

- Water-tube boiler.

- Natural Circulation boiler.

- Boiler that uses forced circulation.

20). What is the largest pump in thermal power plant?

In a thermal power plant, the largest pump is the Boiler Feed Pump (BFP), which provides water to the boiler.

21). How to achieve generator synchronization in a thermal power plant?

Before connecting a generator, its voltage, frequency, phase sequence, & phase angle must be synchronized with the grid.

To control the speed and voltage of the generator, synchronization equipment such as

- Synchroscopes,

- Automated Voltage Regulators (AVR), and

- Governors are used.

22). How does one can manage reactive power in a thermal power plant?

Reactive power is managed by equipment such as capacitor banks, reactors, and Automatic Voltage Regulators (AVRs).

The purpose is to keep voltage levels below acceptable ranges while also ensuring the efficient operation of power plant.

Reactive power adjustment is essential for reducing losses and preventing voltage instability in power system.

23). How do you calculate a thermal power plant’s efficiency?

The formula for calculating a thermal power plant’s efficiency is:

Efficiency=[Output (electric power)/Input (fuel energy)] x 100

The plant generates electrical energy, while the fuel provides thermal energy [typically measured in BTUs (or) Joules].

The efficiency is usually given as a percentage, and it is influenced by elements such as

- Fuel quality,

- Boiler,

- Turbine, and

- Generator performance, &

- Effectiveness of heat recovery system.

24). What is a Power Factor and why is it necessary in thermal power plants?

Power factor (PF) is the ratio of real power (measured in kW) to apparent power (measured in kVA) in an electrical system.

It shows the effectiveness with which the electrical power is utilized.

Maintaining a high power factor is essential in a thermal power plant because it decreases losses in the electrical distribution system, improves voltage regulation, and reduces generator and transformer loads.

- Capacitor banks and

- Synchronous condensers

are frequently used to improve power factor.

25). What is the significance of earthing in thermal power plants, & how is it implemented?

Earthing is essential for thermal power plant safety because it allows fault currents to go directly to the ground, saving equipment & personnel from electric shock & damage.

It is implemented with grounding rods, mats, or grids that are linked to the plant’s electrical system.

To ensure its effectiveness, the earthing system’s design must take into account soil resistivity, fault current levels, & safety rules.

Regular testing & maintenance of the earthing system is required to assure its dependability.