What is an Electrical Drive?

An electrical drive is a type of system that is known to be used for the purpose of controlling the motion of an electrical machine. To put it another way, a drive that makes use of an electric motor is referred to as an electrical drive. The major source of power for the electrical drive can be sourced from a variety of different prime movers, including

- Diesel or gasoline engines,

- Gas or steam turbines,

- Steam engines,

- Hydraulic motors, and

- Electrical motors.

This primary mover supplies the drive with the necessary mechanical energy to control the motion.

How do electrical drives operate?

Power is fed into the drive by positioning it between the electrical supply and the motor, and the drive then controls and regulates the power fed into the motor. This enables control of speed, direction, acceleration, deceleration, torque, and, in some cases, motor shaft position.

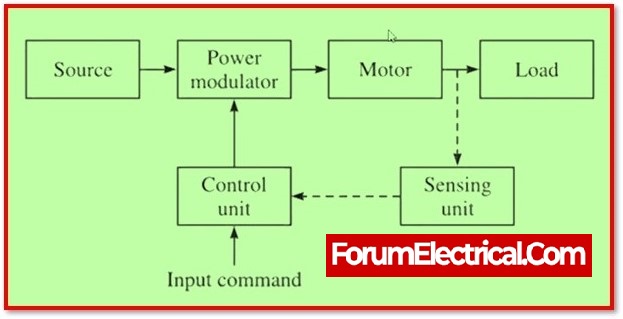

Block Diagram of an Electrical Drive:

The following figure is a typical block diagram representations of an electric drive system:

The system includes

- Power supply,

- Power electronic converter,

- Motor,

- Load,

- Control unit, and

- Sensing unit.

1. Power Source:

Power Source is in responsible of supplying the power required by the system to perform the intended operation.

2. Power Electronic Converter:

This equipment is in control of converting the provided electrical energy into a form that can drive the motor (generally mechanical energy).

The power controller regulates the amount of power supplied to the motor that it can handle. Essentially, this control is necessary since the power that passes through the system determines the torque-speed characteristics required by the load.

When transient actions such as starting, braking, and so on occur within the system, this device assists in restricting the current to particular levels in order to avoid voltage overloads or dips.

There are various sorts of power converters, and we have written a separate article about them.

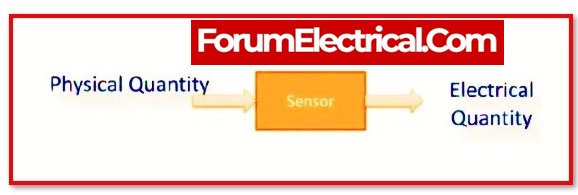

3. Control and sensing units:

Under closed-loop operation, this unit controls the power converter based on the given input as well as the feedback signal obtained from the load. To have the right operating conditions, the control unit works in concert with the sensor unit, which actually senses the voltage or current signal as feedback. The sensing unit is in charge of detecting the motor’s current or speed. It also protects and operates in a closed loop.

4. Electric Motor:

This is primarily responsible for converting applied energy into mechanical motion. The majority of DC motors used in electric drive systems are in series, shunt, or compound configurations, whereas AC motors are slip ring induction motors. In other applications, stepper motors or brushless DC motors are also employed.

5. Load:

The load is a component of the system that is specified based on the torque/speed characteristics of the system, such as

- Pumps,

- Machines, and so on.

In terms of torque-speed characteristics, the electric motor and load are compatible with one another.

Types of Electrical Drives:

There are several factors on which electric drives are classified; however, electric drives are primarily classified based on power supply into two categories:

- AC Drives and

- DC Drives

Electrical Drive are often divided into three categories

- Group drive,

- Individual drive, and

- Multi-motor drive.

Furthermore, these drives are further classified depending on the many factors stated below:

Electrical drives are grouped into two types based on their operating speed:

- constant speed drives and

- Variable speed drives.

Electrical drives are divided into two categories based on the number of motors:

- Single motor drives and

- Multi-motor drives.

Based on the control parameter, electrical drives are separated into two types:

- Stable torque drives and

- Stable power drives.

1). AC Drives:

An alternating current drive (AC drive) is a device that regulates the speed of an electrical motor in order to:

- Improve process control

- Minimise energy consumption and generate energy more efficiently

- Mechanical stress reduction in motor control applications

- Optimise the operation of numerous electric motor-powered applications

Drives can also be used to convert energy from natural and renewable resources such as the sun, wind, and tides and transfer it to the electrical grid or utilize it domestically. AC drives are utilised in hybrid technologies to combine traditional energy sources and energy storages to produce entire energy management solutions.

The operation of AC drives is dependent on the type of AC power input. These are lighter than DC drives.

- Induction motor drives and

- Synchronous motor drives

are the two types of AC drives.

AC drives are also known as variable frequency drives, adjustable speed drives, variable frequency drives, variable speed drives, frequency converters, inverters, and power converters.

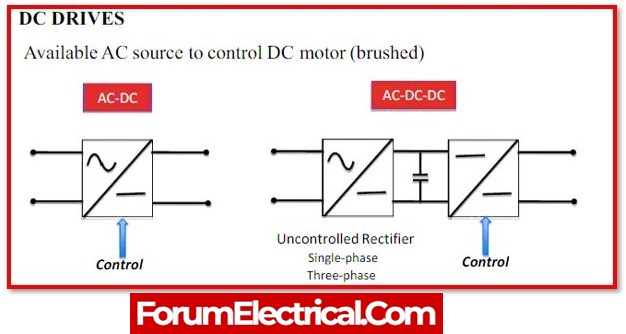

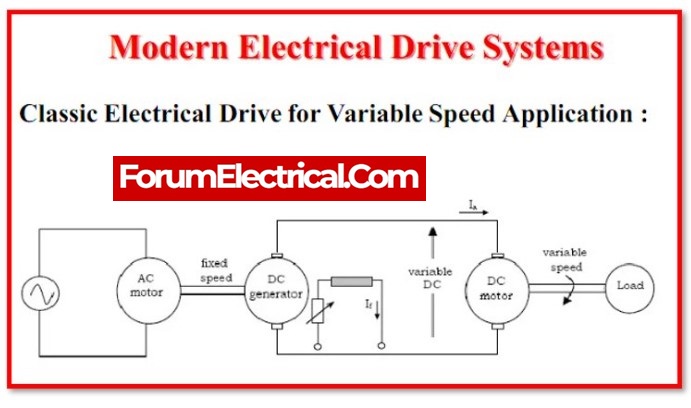

2). DC Drives:

A direct current drive, often known as a DC drive, is a system for controlling the speed of DC motors that works by converting the input alternating current supply into direct current with the help of a converter circuit that uses rectifiers like diodes and thyristors. Previously, DC generators were responsible for producing variable DC voltage, which was then used to control the speed of DC motors.

DC drives are those in which the motive force that excites the system is DC in nature. Their primary applications include

- Variable(Adjustable) Speed Drives and

- Position Control.

DC motors are employed along with power electronic converters.

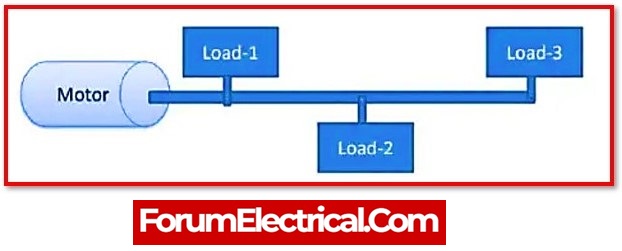

3). Group Drive:

The term “group drive” refers to a method in which multiple machines are mounted on a single shaft and are powered by a single large motor. A large motor, usually referred to as the main motor, powers a common shaft in a group drive, hence this type of drive is also known as line shaft drive. Using pulleys with multiple steps, a number of smaller machines are connected to the central shaft of the larger machine.

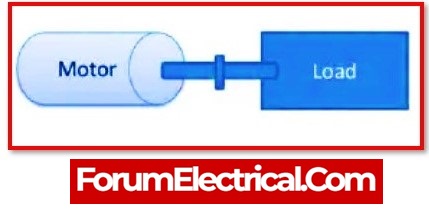

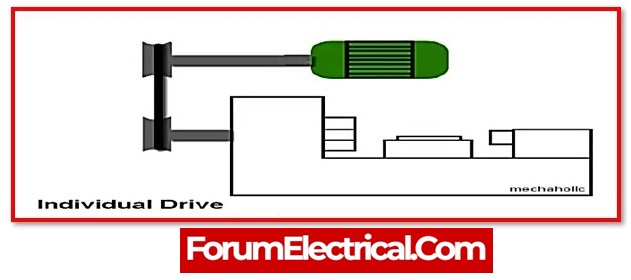

4). Individual Drive:

If only one electric motor is utilised in a system to drive or impact energy for the operation of a single machine, that electric motor is included in the category of individual drive. When an individual drive is employed, the function that is being carried out can be done so in a more secure network.

Individual drives can be used in situations where a constant speed is necessary, such as in

- Paper mills and

- Textile sector.

This drive is also employed in single spindle drilling machines, as well as numerous varieties of electrical hand tools and some metal-working machine tools.

Driving large machinery such as

- Cranes,

- Lifts,

- Lathes

requires the use of individual drives, which are the only available option.

In a wide variety of different types of individual drive applications, the electric motor is an essential component of the machine.

5). Single-Motor Drive:

Single motor is used to power multiple pieces of equipment by way of a line shaft or belt. Because of cannot change the speed of every load independently, it is both inflexible and inefficient. The single motor, single load drive is the most typical type of drive. Each load has its own individual motor that is always running.

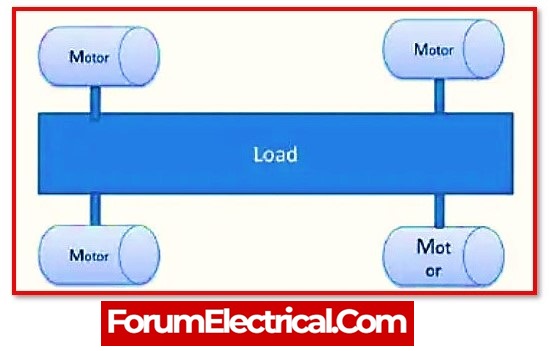

6). Multi-Motor Drive:

A multi-motor electric drive is a type of mechanism that refers to an electric drive that employs multiple motors for the purpose of running multiple parts of the same machine.

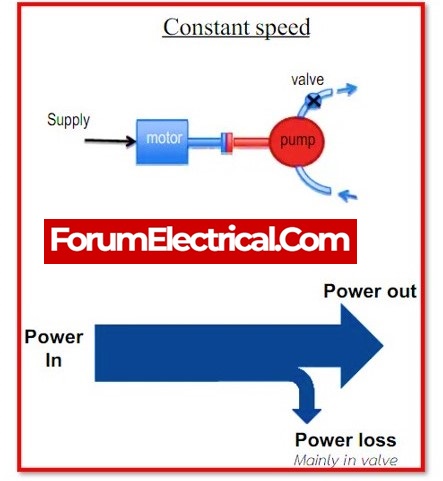

7). Constant Speed Drive:

A constant speed drive (CSD), also known as a constant speed generator, is a form of transmission that takes power from an input shaft that rotates at a wide – range of speeds and delivers it to an output shaft that rotates at a constant speed, despite the fluctuating input. They are used to power mechanisms that require a steady input speed, such as electrical generators.

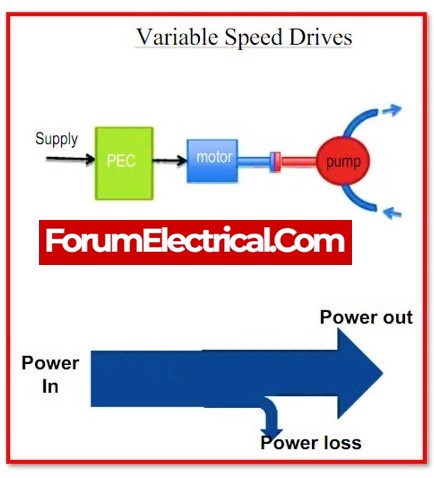

8). Variable Speed Drive:

Variable speed drives (VSD) also known as variable frequency drives (VFD), are an important tool for energy managers.

- A three-phase AC induction motor and

- A variable frequency power source

are typical components of a VSD system.

The variable frequency power supply generates a pulse-width modulated current that changes the power and frequency provided to the motor. This allows for precise control of the motor speed across a wide range. VSDs are used in pump and fan applications to alter the pump or fan speed based on demand, frequently resulting in significant energy savings.

9). Stable Torque Drive:

When the torque produced by the motor and the torque produced by the load are equal, a motor-load system is said to be operating at equilibrium speed which is called as steady torque drive. Drive will run in a steady state at this speed as long as it is the speed at which stable equilibrium can be maintained.

10). Stable Power Drive:

Stable power drive is the ability of an electric power system to regain a state of operating equilibrium after being forced to a physical or electrical disturbance, with system variables controlled so that basically the entire power system remains intact. The above potential is measured relative to a given initial operating condition of the electric power system.

Why are electrical drives required?

Electrical drives permit the use of a wide range of power, from milliwatts to megawatts, for varying speeds, lowering the overall cost of operation of the system.

- To improve the speed and precision of motor stopping and reversing operations

- To regulate the initial current

- To offer safeguards

- To establish advanced control with variable parameters such as temperature, pressure, level, and so on.

The advancement of power electronic devices, microprocessors, and digital electronics has resulted in the development of modern electric drives that are more compact, efficient, cheaper, and have higher performance than the bulky, inflexible, and expensive conventional electric drive system that uses a multi-machine system to produce variable speed.

Why do motors use drives?

A motor’s speed, torque, and direction, as well as the horsepower it generates, are all under the control of the motor’s drive. In most cases, DC drives are used to control a shunt-wound DC motor, which is characterised by having unique armature and field circuits. AC drives, similar to their DC counterparts, control speed, torque, and horsepower in AC-induction motors. AC drives also control the flow of alternating current through the motor.

Advantages of Electrical Drive:

- Electric drives are environmentally safe because they do not emit smoke, fumes, or ash. As a result, electric drives are appropriate for underground and tube railways.

- Electric drives are flexible although their performance can be successfully regulated with electronic devices such as SCRs, IGBTs, and microcontrollers.

- Available in a wide variety of torque, speed, and power.

- Electric drives are smaller in size and take up less space.

- They do not require any warm-up time and may be started quickly.

- Remote control is available for electric drives.

- A dependable source of motivation.

- Powered by electrical energy, which provides several advantages over other forms of energy.

- Adaptable to a variety of operating situations, including submersion in liquid, explosive chemical or mining environment, radioactive environment, and so on.

- Electric drives provide a high schedule speed and a high traffic handling capacity, requiring less terminal area.

- Reduce maintenance costs and time. Electric drives are cost-effective.

Disadvantages of Electrical Drive:

- The capital cost of setting up an electric drive is expensive.

- Electric drives are only suitable for electrified railways.

- Electric drives require additional control circuitry.

- Electric drives can sometimes produce noise pollution.

- Electric drives have a weak dynamic response.

- A power outage can entirely disable an electric power train.

- The output power of an electric drive is low.

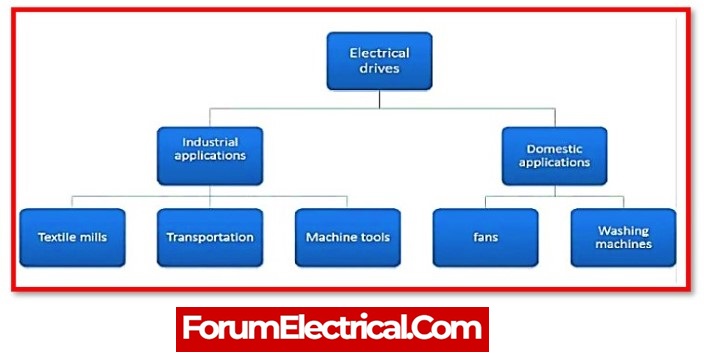

Applications of Electrical Drive:

- Pumps,

- Fans,

- Motors,

- Transportation systems,

- Turbines,

- Engines, and

- Other industrial and home applications

are among the many uses for electric drives.

It may be used in a variety of electric tractions such as

- Trains,

- Buses,

- Trolleys, and

- Solar-powered vehicles.

- Lathe machines,

- Shears,

- Frequency converters,

- Air compressors,

- Refrigeration and

- Air conditioning,

- Belt conveyors

are some other applications.