- What is Induction Motor?

- Construction of Induction Motor

- How an Induction Motor Works (Working Principle of Induction Motor)

- Types of Induction Motors

- Single Phase Induction Motor

- Types of Single-Phase Induction Motor

- Three Phase Induction Motor

- Types of Three Phase Induction Motor

- How does an induction motor start?

- Why three phase induction motor is a self-starting?

- Why does a single-phase induction motor not self-start?

- Synchronous Speed Calculation of Induction Motor

- Slip of Induction Motor

- Advantages of Induction Motor

- Disadvantages of Induction Motor

- Applications of Induction Motor

A motor’s primary function is to convert energy from one form to another, such as from electrical to mechanical. Based on the kind of power source, such as AC or DC, motors may be categorised. There are several types of motors under these AC & DC motors, including

- Induction motors,

- Reluctance motors,

- DC shunt,

- PMDC,

- Stepper,

- Synchronous, etc.

An overview of the many kinds of induction motors and how they operate is covered in this post.

Since it operates at a lower speed than synchronous speed, this motor also known as an asynchronous motor and is the most widely used AC motor.

Synchronous speed is simply referred to the rotational magnetic field’s speed inside the stator.

What is Induction Motor?

Induction Motors are the most common type of motor that may be used in a wide range of applications.

Induction motors always operate at a speed that is slower than synchronous motors, so that these machines are often referred to as asynchronous motors.

The speed of the rotating (rotational) magnetic field in the stator is referred to as the synchronous speed.

The electric current in the rotor of an induction motor that is required to create torque is acquired by electromagnetic induction from the spinning (rotating) magnetic field of the stator winding. This is necessary for an induction motor.

Construction of Induction Motor

1). Stator

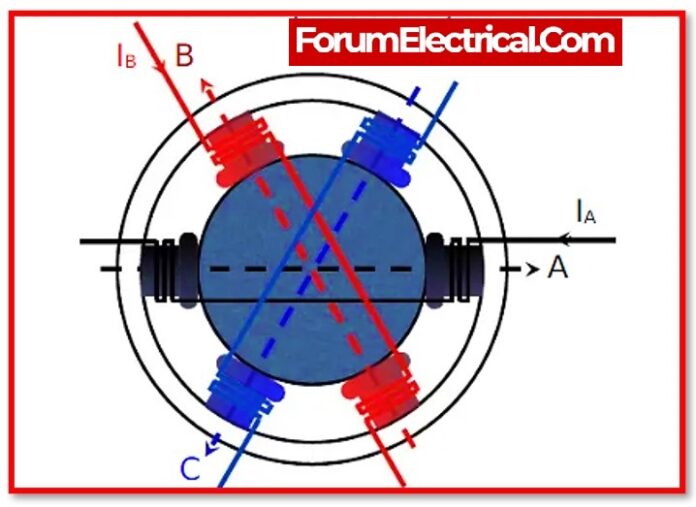

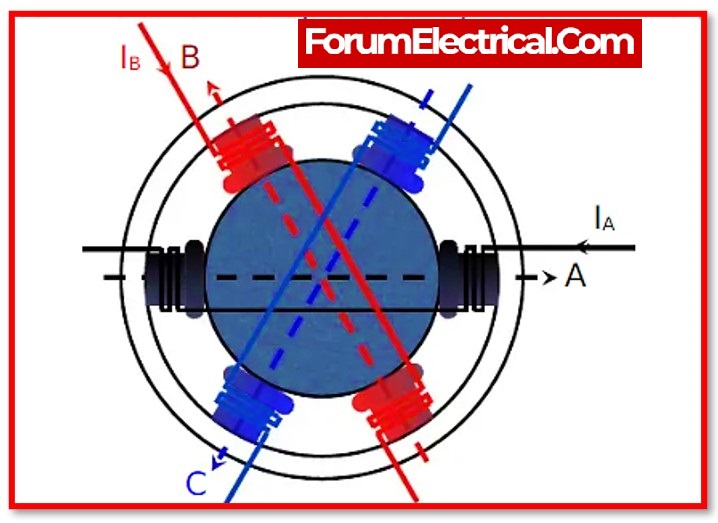

The stator is built up of a variety of stampings, each of which has slots to accommodate three-phase windings.

A certain number of poles are required for its winding. The windings are geometrically split into segments that are 120 degrees apart from one another.

2). Rotor

The rotor is the electromagnetic circuit’s rotating component.

- Squirrel cage rotors and

- Wound rotors

are the two types of rotors that may be found inside of induction motors. There is no need for a DC field current in order to operate the machine.

Instead of being physically linked by wires, rotor voltage is generated via inducing current in the rotor’s windings.

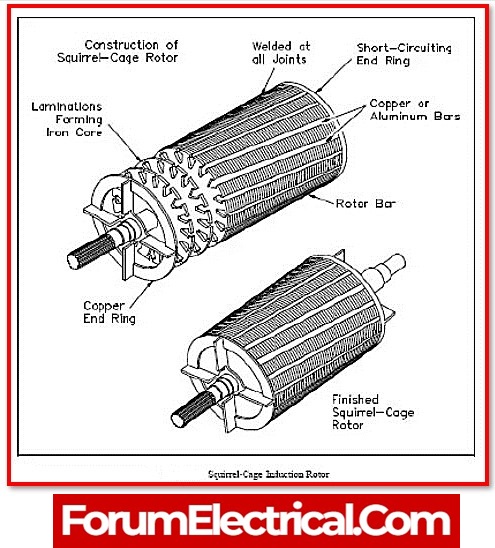

The squirrel cage rotor is the most popular form of rotor. The rotor is made out of a cylindrical laminated (laminations) core with parallel slots arranged axially to carry the conductors.

Each slot contains a bar of copper, aluminium, or alloy. The rotor of the three-phase induction motors is frequently used as an anchor.

The anchor form of the rotors employed in very early electrical equipment.

The magnetic field would induce the anchor’s winding in electrical equipment, but the rotor performs this function in three phase induction motors.

3). Coil

Within the stator, all of the coils will be wrapped (encased) around the grooves.

The coils, however, are wrapped (encased) around the inside of the stator frame in loops around the inner circle of the stator, and electricity will flow via these coils.

When the energy flows through them, it creates a magnetic field, which causes the motor to spin.

How an Induction Motor Works (Working Principle of Induction Motor)

The principle (operation) of an induction motor is based on the concept of electromagnetic induction. An induction motor has two windings:

- Stator winding &

- Rotor winding.

When the input AC supply is linked to the stator winding and the current flowing in the stator winding creates a magnetic flux.

Since this magnetic flux is generally revolving, it is sometimes referred to as a rotating magnetic field. The rotor winding of an induction motor is a short-circuit winding.

The stator’s revolving magnetic flux cuts the rotor winding’s short-circuited conductors. According to Faraday’s law of electromagnetic induction, an EMF is generated in the rotor circuit, causing a current to flow through it.

As current runs through the rotor winding, additional magnetic flux is created in the machine.

As a result, the induction motor has two magnetic fluxes:

- Stator flux and

- Rotor flux.

These two magnetic fluxes interact with one another. As a result, the rotor experiences torque, causing it to revolve in the direction of the stator’s revolving magnetic field. An induction motor works in this method.

Types of Induction Motors

Depending on the type of input supply, induction motors can be classified as

- Single Phase Induction Motor and

- Three Phase Induction Motor

Single Phase Induction Motor

The induction motor with a single phase does not have a self-starting function. Alternating current flows through the main winding of the motor if it is connected to a power source that only has a single phase.

It is reason that the sorting engine that requires the least amount of money and the least amount of maintenance should be the one that is used the most.

Since they do not start independently, they come in a variety of forms, each of which is defined by the method in which they are energized. These motors have a

- Shaded pole,

- Split phase, and

- Capacitor motors.

Again, capacitor motors are classified as

- Capacitor start,

- Capacitor run, and

- Permanent capacitor motors.

The motor with the permanent capacitor is used.

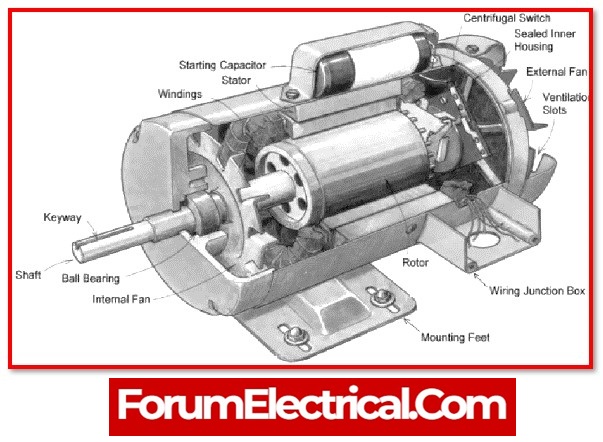

With motors of this type, the start winding may either contain a series capacitor (or) a centrifugal switch.

Both of these components are optional. Because of the impedance of the main winding, the supply voltage always precedes the current that is flowing through the main winding when the supply voltage is applied.

And the current that flows through the start winding either leads (or) lags the supply (input) voltage depending on the impedance of the starting mechanism.

There is a sufficient phase difference between the two windings to the angle that separates them, which allows for a rotating magnitude field to be generated, which in turn produces a starting torque.

After the motor has reached between 70 and 80 percent of its synchronous speed, a centrifugal switch located on the motor shaft will open and disconnect the starting winding.

Types of Single-Phase Induction Motor

Single-phase induction motor is further classified into four different types of induction motors,

- Split Phase Induction Motor,

- Capacitor StartInduction Motor,

- Capacitor Start & Capacitor RunInduction Motor, and

- Shaded Pole Induction Motor.

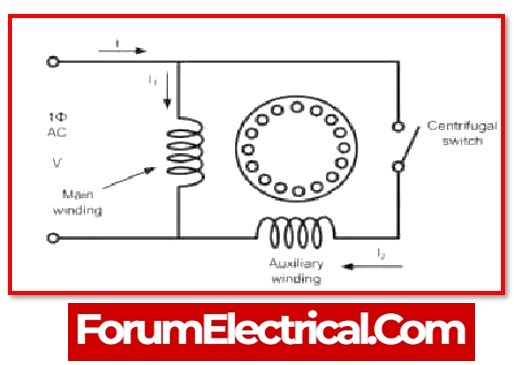

1). Split Phase Induction Motor

Resistance Start Motor is another term for a split-phase induction motor. This kind of motor has a stator and a rotor with a single cage, and the stator has two windings

- Starting winding and

- Main winding.

These two windings are shifted (moved) in space by 90 degrees. Whereas the main winding has a very low resistance and a strong inductive reactance, the starting winding has less inductive reactance & a higher resistance.

This kind of motor is more affordable and suitable for simply starting loads when the starting frequency may be limited. Because of its lower starting torque, this motor cannot be used for drives that need more than 1 KW.

- Washing machines,

- Floor polishers,

- AC fans,

- Mixer grinders,

- Blowers,

- Centrifugal pumps,

- Drilling &

- Lathe machines

are example for split-phase induction motors.

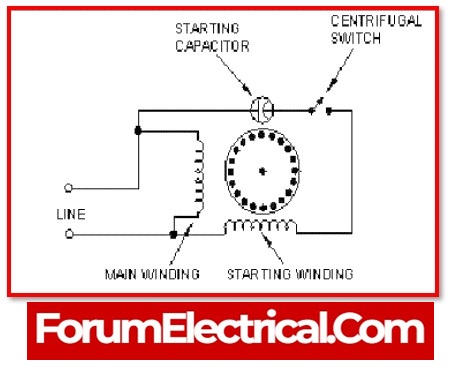

2). Capacitor Start Induction Motor

A capacitor start induction motor is a single-phase motor with a stator and rotor enclosed in a single cage. This motor’s stator is made up of two windings:

- Primary winding and

- Auxiliary winding.

Starting winding is another term for an auxiliary winding. In motor construction, these two windings may be arranged 90 degrees apart in space.

If frequent starts are required, such as with larger inertia loads, a capacitor start induction motor is employed.

This kind of motor is employed to drive power compressors, pumps, machine tools & conveyors.

It is found in AC compressors and freezers.

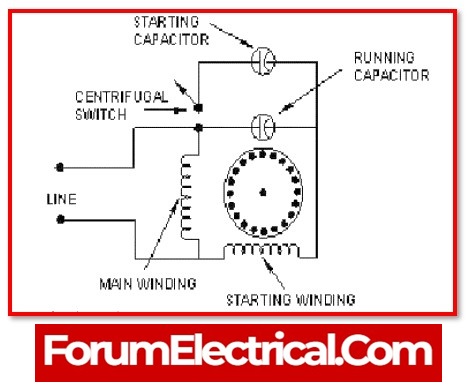

3). Capacitor Start and Capacitor Run Induction Motor

The operating concept of a capacitor run induction motor is the same as that of a capacitor start induction motor. Singlephase induction motor does not self-start because the magnetic field produced is not rotational. Induction motors need phase difference to generate a rotating magnetic field. With a splitphase induction motor, resistance is required to produce a phase difference; however, in these motors, the capacitor produces a phase difference.

The current passing through the capacitor does, in effect, influence the voltage. There are two windings in a capacitor start capacitor run motor:

- Main winding and

- Starting winding.

There is a connection inside the capacitor in the starting winding, so the current providing within the capacitor controls the applied voltage via some angle.

These two motors have a strong starting torque and are often used in grinders,

- Conveyors,

- Compressors,

- Air conditioners and other similar applications.

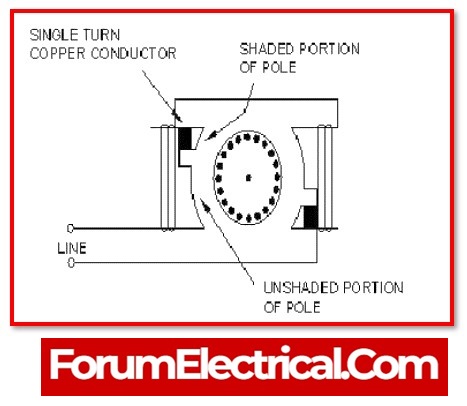

4). Shaded Pole Induction Motor

This is a self-starting single phase induction motor with the copper ring, also known as the shaded ring, shading one of the motor’s poles.This ring’s primary role in the motor is similar to a secondary winding.

This kind of motor only rotates in one direction, and reverse movement is not feasible.

The power losses in this motor are extremely high and the power factor is low, and the induced starting torque can be extremely low. Because of its small size and low power ratings, this motor has a low efficiency.

Because of their ease of starting and inexpensive cost, shaded pole induction motors are used in tiny devices such as

- Fans and

- Relays.

This motor also be used in

- Hairdryers,

- Exhaust fans,

- Table fans,

- Air conditioning,

- Cooling fans,

- Refrigeration devices,

- Record players,

- Projectors,

- Tape recorders, and

- Photocopying machines.

These motors may also be used to start electronic clocks and single-phase synchronous timing motors.

Three Phase Induction Motor

Three-phase induction motors are self-starting and do not need

- Capacitor,

- Start winding,

- Centrifugal switch, or any other kind of starting mechanism.

- Industrial and

- Commercial applications

employ three phase AC induction motors extensively.

These Induction motors are utilised in industrial and household appliances because they are durable, require little maintenance, are relatively inexpensive, and only require power to the stator.

Types of Three Phase Induction Motor

A three-phase induction motor contains two key components: the stator and the rotor. The stator is the motor’s stationary component, while the rotor is its rotating component.

The load is linked to the shaft of this motor. The stator can be wound with a three-phase armature winding.

After a balanced three-phase current is supplied throughout this winding, a steady amplitude rotating magnetic field inside the air gap may be generated.

This armature winding, which is connected to the three-phase power supply, carries the load current.

Three phase induction motors are divided into two types,

- Squirrel cage Induction Motor and

- Slip Ring or Wound Rotor Induction Motor

1). Squirrel cage Induction Motor

The squirrel cage induction motor is extremely simple to assemble. The rotor in this motor has a cylindrical core capable of being laminated and some certain slots on the external periphery. These slots are not comparable and are twisted at various angles.

These slots help to prevent magnetic locking between the teeth of the stator & rotor and allows for smooth operation & reduced humming noise.

These motors have rotors of bars in position of rotor windings, and these bars are made of brass, aluminium, or copper.

The rotor winding in this kind of motor contains an aluminium bar or else uninsulated copper fitted into semi closed rotor slots.

These conductors are short circuited at both ends of this motor by a comparable material’s end ring.

As a result, because this type of rotor resembles a squirrel cage, it is known as a squirrel cage induction motor.

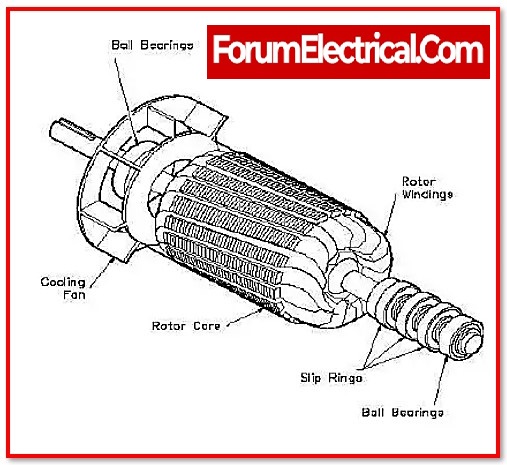

2). Slip Ring or Wound Rotor Induction Motor

A winding rotor motor is another name for a slip-ring induction motor. The rotor of this motor has a laminated cylindrical core.

There are several slots on the outside perimeter, identical to the squirrel cage. The rotor winding is inserted into the slots.

The insulated windings are wound (arranged) on top of the rotor in the same way as they are on the stator. This rotor’s windings may be distributed equally and are often coupled in the STAR paradigm.

This STAR connection’s three terminals may be removed from the slip ring. So, this motor is called as a slip ring induction motor.

How does an induction motor start?

A three phase induction motor has the capability of self-starting. When the power supply is linked to the stator of a three phase induction motor, a rotating magnetic field is generated. This causes the rotor to start rotating, which in turn causes the induction motor to start operating. While the motor is being started, the slip in the motor is at unity, & the starting current is a very high.

A starter function includes more than simply turning on the motor; rather, it is responsible for the two primary operations,

- In order to lower the high starting current.

- To give protection against over voltage and under voltage.

To start the process of starting the three-phase induction motor, just connect the motor directly to full voltage of the supply. Applying a lower voltage to the motor might also be another method for starting the motor. The induction motor produces torque in a method that is proportional to square of the input voltage. Because of this, a motor will produce a larger amount of torque when it is started on the full voltage rather than when it is started on the decreased voltage.

Why three phase induction motor is a self-starting?

A 3-phase motor has three single-phase lines with a phase difference of 120°. As a result, the rotary magnetic field has a comparable phase difference, and this phase difference rotates the rotor.

Ex: if assume a, b, and c to be three phases, after phase ‘a’ is magnetised, the rotor will move towards phase ‘a’. In the following second phase, ‘b’ will be magnetised, magnetising the rotor, and then ‘c’. The rotor will continue to revolve in this manner.

Why does a single-phase induction motor not self-start?

When a single phase supply is applied to a single phase induction motor, it creates a pulsing magnetic field rather than a rotating magnetic field.

The current supply in a conductor creates a flux that may be divided into two components, each of which rotates in the opposite direction at a comparable speed.

As a result, the net flux is zero, the current flow generated in the rotor conductors is zero, and the torque is zero. As a condition, a single-phase induction motor does not start by itself.

To overcome this problem and make this motor self-starting, it may be momentarily transformed into a two-phase motor during start.

As a result, the stator of a one-phase motor is provided by supplementary winding to the main winding, such as starting winding. As a result, these windings are distributed over the single-phase supply.

The winding may be configured in such a way that the phase difference between the currents in the two stator windings is exceedingly huge.

As a result, this motor operates in the same manner as a two-phase motor. The two currents create a spinning flux, which causes the single-phase motor to self-start.

Synchronous Speed Calculation of Induction Motor

The speed at which the rotating magnetic field is rotating is referred to as the synchronous speed.

Ns = 120f/P

Where,

Ns– Synchronous Speed,

f – Supply Frequency and

P – Number of Poles in Motor.

Slip of Induction Motor

Rotor spins as it strives to equal the synchronous speed of the stator field. Rotor, however, is never able to catch up in practical terms.

There won’t be enough relative speed between the stator flux & the rotor if the rotor catches up to the stator speed, hence there won’t be any induced rotor current or torque generation to keep the rotation going.

While the engine may slow down as a result of the lost torque, the torque will rapidly be applied once more owing to relative speed. Because of this, the rotor spins at a speed that is constantly lower than the synchronous speed.

Slip refers to the difference between the rotor’s real speed (N) and its synchronous speed (Ns).

% Slip = [(NS-N)/NS] x 100

Advantages of Induction Motor

1). Low Cost

Induction machines are fairly inexpensive when compared to synchronous & DC motors. The modest induction motor design causes this. Thus, these motors are preferred for fixed-speed industrial and commercial/domestic applications with AC line power.

2). Low Maintenance Cost

Induction motors are maintenance-free. The design of an induction motor is simply basic & maintenance is also very uncomplicated, resulting in minimal(low) maintenance cost.

3). Ease of Operation

Since the revolving coils’ low resistance allows power and current to be induced by the transformer’s movement on the rotor, the induction motor’s operation is simple. Induction motors self-start. Maintenance may be simpler.

4). High Starting Torque

The initial torque of the induction motor is rather high which makes the motor beneficial for actions where the load is applied (load connected) before the starting of the motor. Unlike synchronous motors, 3-phase induction motors have self-starting torque. Auxiliaries rotate single-phase induction motors because they lack self-starting torque.

5). Durability

Durability is another benefit of induction motors. This makes it flexible. The motor operates for years without maintenance.

6). Change Speed

The speed variation of the induction motor is essentially constant. Speed changes by a few percent from no load to rated load.

Disadvantages of Induction Motor

- The power factor is extremely low in a light load situation, and it draws a large current. Thus, the copper loss can be substantial which affects the efficiency all throughout light load situation.

- The starting torque of the squirrel cage induction motor is not particularly low.

- This motor has a high starting inrush current, which results in a voltage drop at the start of time.

- This is an invariable speed motor, and therefore is not suitable for applications requiring irregular speed.

- This motor speed control is difficult.

Applications of Induction Motor

The applications of induction motors are

- Hoists

- Large capacity exhaust fans

- Driving lathe machines

- Lifts

- Cranes

- Crushers

- Oil extracting mills

- Textileetc.

These are the function of the induction motors and their types and their applications in different sectors.