Power transformers are essential components of the electrical system. Their failure not only damages equipment, but also affects the entire networks, causes costly outages, & affects public safety.

Despite the high effects, research indicates that more than 70% of transformer failures are preventable.

Why does Power Transformer Failure Occur?

Many engineers fail to see early warning signs or act appropriately. Understanding the underlying causes, their impact, and the appropriate solutions is essential to designing dependable, long-lasting transformer systems.

Many of these faults, from overheating & insulation breakdown to inadequate maintenance procedures, are the result of ignored warning indications and delayed response.

In this post, we’ll look at the seven most prevalent causes of power transformer failures, explain how they influence your system, and offer practical, field-tested remedies to prevent them in early stages.

Here are 7 common causes of transformer failures & how you can repair them before they worsen.

1). Overheating

2). Insulation Breakdown

3). Oil Contamination & Degradation

4). Electrical Surges & Lightning Strikes

5). Short Circuits & Internal Faults

6). Mechanical Stresses & Vibrations

7). Poor Maintenance & Inadequate Monitoring

1). Overheating

Cause

Overheating typically occurs due to

- Overloading,

- Cooling system failure, (or)

- Inadequate ventilation.

When transformers operate beyond their rated capacity, excess heat builds up in the windings & insulation, degrading their performance.

Effect

Prolonged overheating leads to

- Insulation breakdown,

- Oil degradation, &

- Catastrophic failure.

Hotspots can develop, reducing the lifespan of the transformer significantly.

Solution

- Implement a load management strategy to prevent overloading.

- Use forced air/oil cooling systems or install radiator fans to improve heat dissipation.

- Continuously monitor oil and winding temperatures using sensors (or) SCADA systems to take timely action.

2). Insulation Breakdown

Cause

Insulation systems degrade over time due to

- Moisture ingress,

- Thermal aging, and

- Voltage surges.

Water contamination & mechanical wear further weaken insulation strength.

Effect

Compromised insulation can lead to

- Partial discharges,

- Arcing, (or)

- Electrical flashovers inside the transformer.

This might result in internal faults that are expensive & time-consuming to repair.

Solution

- Schedule dielectric strength testing (BDV tests) regularly.

- Install silica gel breathers & ensure conservators are sealed properly to prevent moisture intrusion.

- Replace aged insulation & use drying ovens (or) vacuum drying techniques for moisture removal during maintenance.

3). Oil Contamination & Degradation

Cause

Transformer oil deteriorates due to

- Moisture,

- Oxidation,

- Metallic particles, and

- Sludge formation.

External contamination (or) internal chemical reactions can reduce its insulating and cooling properties.

Effect

Contaminated oil loses dielectric strength and fails to dissipate heat effectively, leading to electrical breakdowns, & eventually internal arcing (or) insulation damage.

Solution

- Perform Dissolved Gas Analysis (DGA) & Furan testing periodically to detect early-stage degradation.

- Use oil filtration machines and vacuum dehydration units to restore oil quality.

- Replace oil when necessary and maintain strict oil handling procedures.

4). Electrical Surges & Lightning Strikes

Cause

- Lightning strikes,

- Switching operations,

- External faults

can create high-voltage transients.

These surges can travel through the grid and reach the transformer without adequate protection.

Effect

Such high-voltage impulses can cause

- Winding insulation damage,

- Flashovers, and

- Bushing explosions.

In severe cases, it can destroy the transformer in seconds.

Solution

- Install high-quality surge arresters at strategic locations, particularly at incoming lines.

- Enhance grounding systems & use shield wires (or) lightning masts to divert surges away.

- Coordinate protection relays to isolate surge-prone sections during events.

5). Short Circuits & Internal Faults

Cause

Internal short circuits often result from

- Insulation failure,

- Winding displacement,

- Loose connections.

External faults with high current can also stress internal components.

Effect

Internal faults lead to

- Arcing,

- Excessive heating, and

- Gas formation

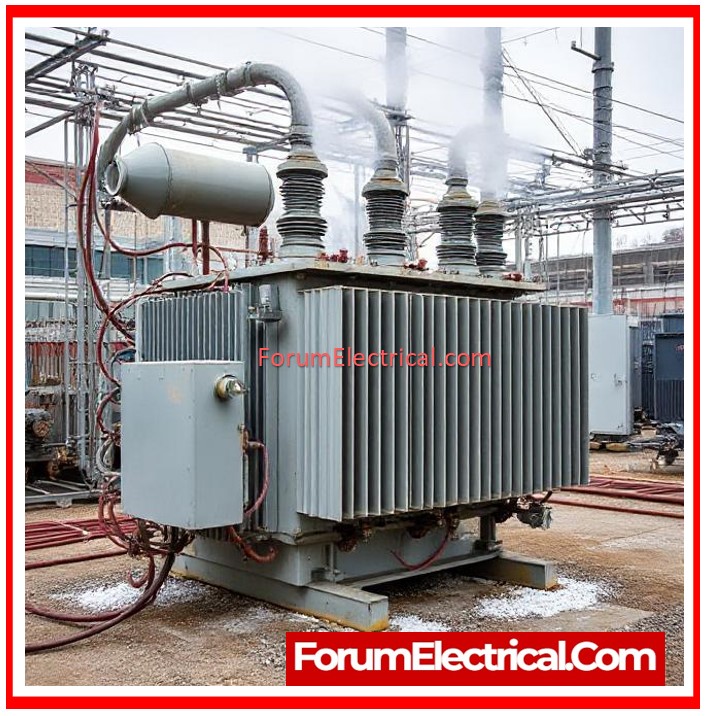

which could result in tank rupture (or) fire if not detected early.

Solution

- Conduct winding resistance tests, turns ratio tests, & insulation resistance measurements during preventive maintenance.

- Ensure all terminal connections are tightened and free from corrosion.

- Install differential & overcurrent protection relays for the quick fault isolation.

6). Mechanical Stresses & Vibrations

Cause

Mechanical stress can result from transportation damage, poor installation, or frequent switching operations.

Even minor misalignments can lead to significant long-term wear.

Effect

These stresses can cause core shifting, loosening of winding clamps, and even bushing damage, affecting the overall structural integrity of the transformer.

Solution

- Utilize vibration dampers, shock absorbers, and rigid mounting systems to reduce mechanical impact.

- After transport (or) installation, conduct vibration analysis and infrared thermography to check for looseness or hotspots.

7). Poor Maintenance & Inadequate Monitoring

Cause

Transformers often suffer from neglected maintenance, infrequent inspections, & outdated monitoring systems.

Budget cuts (or) lack of trained personnel can exacerbate the issue.

Effect

Without proper monitoring, early warning signs like

- Temperature spikes,

- Gas generation,

- Moisture ingress go unnoticed

can lead to failure when it’s too late to act.

Solution

- Adopt SCADA or IoT-based monitoring systems for real-time data on critical parameters.

- Schedule routine inspections based on risk and usage.

- Train maintenance teams to identify early failure indicators and use predictive analytics to plan interventions.

Power transformer breakdowns are typically the result of long-term faults that go unreported or untreated. Whether it’s overheating, insulation failure, oil contamination, or bad maintenance procedures, each cause produces warning signs before calamity occurs.

Most transformer failures can be avoided with the proper combination of testing, protection devices, routine maintenance, and experienced engineering analysis.

In modern increasingly demanding power requirements, simply reacting to a failure is insufficient. The future of power system reliability is based on proactive maintenance, predictive monitoring, & continual improvement.

Engineers can extend transformer life, prevent unplanned outages, and increase overall grid stability by recognizing the core causes and implementing targeted solutions.