- What is the purpose of a Fuse?

- Why is a fuse required?

- Construction of a Fuse

- Working Principle of the Fuse

- Characteristics of the Fuses

- Time-Current Characteristics of Fuses

- Different Types of Fuses

- DC Fuses

- AC Fuses

- LV Fuses

- HV- High Voltage Types of Fuses

- Advantages of the Fuse

- Disadvantages of the Fuse

- Application of the Fuses

What is the purpose of a Fuse?

A fuse is the most important component in the field of electronics or electrical because it protects various electrical circuits from overcurrent conditions.

The component includes a metal strip that dissolves when a wide range of current values is applied.

Because of the metal dissolving, the circuit becomes an open circuit, cutting off the flow of power through the device.

It is also known as an ADS (automatic disconnection of supply). This is a low-cost device used to protect electrical circuits in the event of a circuit short or a high range of current magnitudes.

Why is a fuse required?

These are used to protect household appliances from damage caused by high current or overload.

When use a fuse in houses, electrical faults in the wiring are prevented, and the appliances are not damaged by the fire caused by the wire burning.

When a fuse is broken or damaged, an abrupt sparkle occurs, which can cause direct damage to your home appliances.

Various types of fuses are used to protecthome appliances from damage. Fuse types for circuit protection are numerous.

The most common measurement unit for fuse is amperes.

Despite the fact that their functionality is based on the self-production of heat in the presence of additional current via their own developed electrical resistance.

This is generally accomplished by keeping the fuse wire length as short as possible. Because wire length is independent of current rating values, the shortest length of wire imposes the shortest value of resistance.

Construction of a Fuse

A fuse is constructed with a metallic wire with a low resistance that is enclosed in non-combustible material that is not flammable.

It is used to connect and configure in series with a circuit and device that needs to be protected from short circuit and over current.

Electrical appliance may be damaged due to inability to handle excessive current according to their rating limits in case of absence of the fuse and circuit breaker.

A fuse in an electric circuit can be replaced by inserting a new fuse with comparable power rating levels.

It can be formed using elements such as

- Cu (copper),

- Zn (zinc),

- Al (aluminium), and

- Ag (silver).

They also function as a circuit breaker, breaking the circuit when a sudden and unexpected fault occurs in the circuit.

This acts as a safeguard or protector for humans against danger. The fuse is operational in this manner.

Fuse rating = [power (watts)/voltage (volts)] x 1.25

Calculating the fuse rating using the above formula can be used to select a fuse.

- Select the fuse.

- Make a note of the appliance’s voltage (volts) and power (watts).

- Determine the fuse rating.

Use the fuse with the highest rating possible after the result.

Working Principle of the Fuse

The fuse works on the principle of “heating consequence of the current”. It is made from a thin strip or thread of metallic wire. In an electrical circuit, the fuse is always connected in series.

When a high level of current electrical circuits is produced, the fuse softens and the circuit becomes open. The high current flow may cause the wire to collapse and cut off the supply.

This device’s operation is primarily determined by the current’s heating condition. The current will flow normally through the fuse in the normal operation of the current.

Heat will be generated in the fuse element as a result of the current flow, and this heat will be dissipated into the atmosphere.

As a result, the temperature of the heat is kept lower than the melting point values.

In the event of a fault, short-circuited current flow through the device. When compared to normal current magnitude levels, the magnitude of this current value is greater.

This results in the fuse developing a wide temperature range. As a result, the device begins to melt and break down. In this case, the fuse serves as a safeguard against overload or short circuit.

Characteristics of the Fuses

In the electric domain, fuses have a few characteristics that are explained below:

1). Current rating value

Current rating value refers to the frequency with which the maximum number of current passes through the device without melting it. The unit of measurement is amperes, and it has thermal properties.

2). Voltage rating value

The voltage is connected in series with the fuse, which does not increase the voltage rating value.

3). Temperature

The fuse’s functional temperature is increasing, causing the current rating to decrease. This causes the fuse to molten.

4). Voltage drop

When more current flows through the device, the fuse melts, resulting in an open circuit. As a result, the resistance will change and the voltage drop will be minimal.

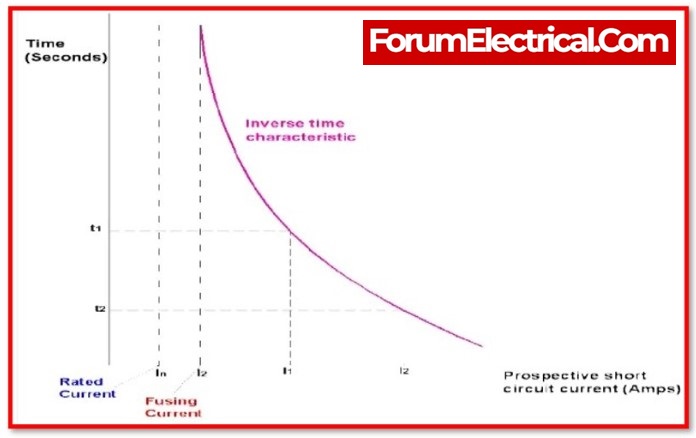

Time-Current Characteristics of Fuses

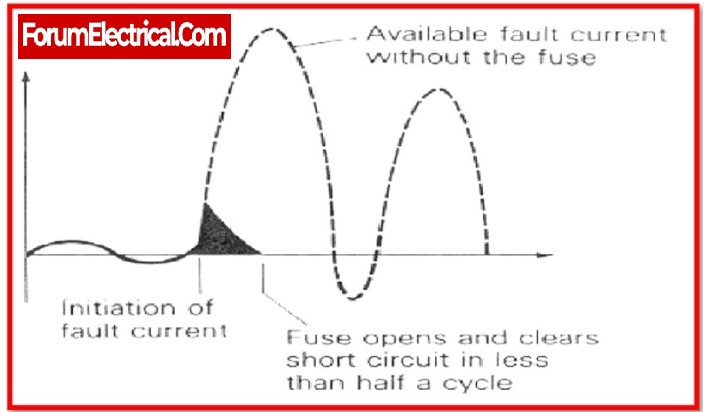

- To adequately protect a cable, the characteristics of the fuse must match the heating characteristic of the cable as closely as possible.

- The fuses have an inverse time characteristic, which means that the greater the over current, the faster the fuse blows.

- Fuse characteristics are drawn on a log/log scale so that a wide range of currents and time intervals can be charted.

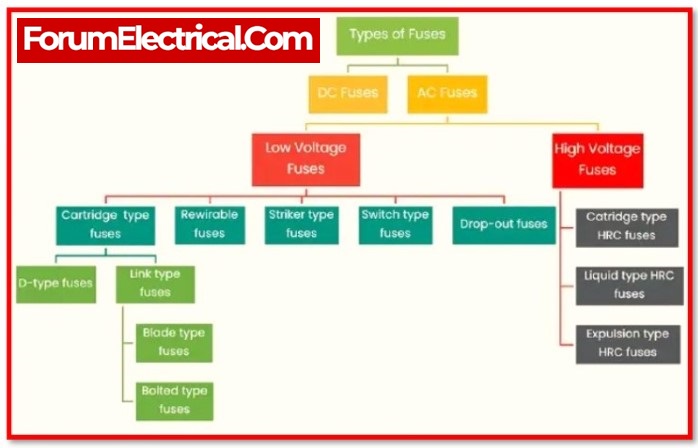

Different Types of Fuses

Fuses are primarily classified into two types based on their application:

- DC type fuseand

- AC type fuse

Fuses are further classified into different types based on voltage levels.

DC Fuses

DC fuses are available in larger sizes and have a constant value over ‘0’ volts, making it more difficult to remove and deactivate the circuit. There is also the possibility of an electric current developing between the molten wires.

To overcome this, a few electrodes are placed at greater distances, resulting in DC fuses of enormous size and complicated construction.

AC Fuses

When compared to DC fuses, AC fuses are smaller in size and have an oscillation rate of nearly 50 to 60 times per second from lowest to highest. As a result, there is no possibility of an electric arc forming between the molten wires.

As a result, they can be crammed into small spaces. Furthermore, AC fuses are divided into two types: HV fuses and LV fuses. The symbols LV& HV stand for low voltage and high voltage, respectively.

LV Fuses

Low voltage fuses are classified into 5 types:

- Re-wirable fuse,

- Cartridge fuse,

- Drop out fuse,

- Striker fuse, and

- Switch fuse.

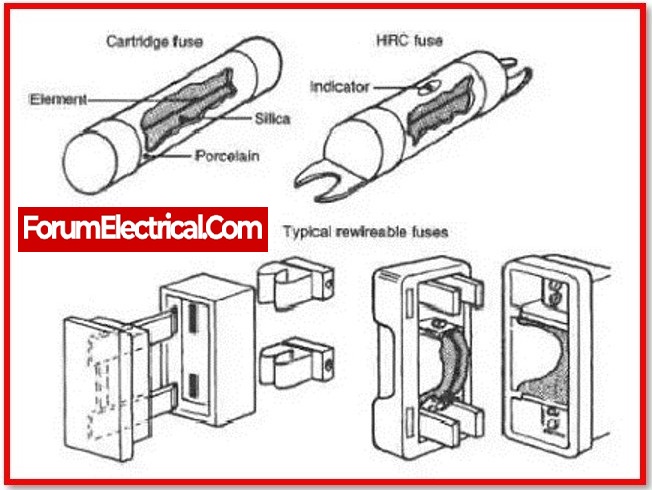

1). Re-wirable Type Fuse

Re-wirable fuses are classified as LV fuses, and they are almost exclusively used in small applications such as wiring in the home, small-scale industries, and other low-current applications.

These fuses have two essential parts: a fuse base with two terminals like in and out, and a fuse. This element is typically made of porcelain. A fuse carrier, which grips the fuse element, is another component of this fuse.

2). Cartridge Type Fuse

Cartridge fuses have completely closed containers and metal contacts. This fuse’s main applications are low voltage (LV), high voltage (HV), and small fuses.

Again, these fuses are divided into two types:

- D-type fuses and

- Link-type fuses.

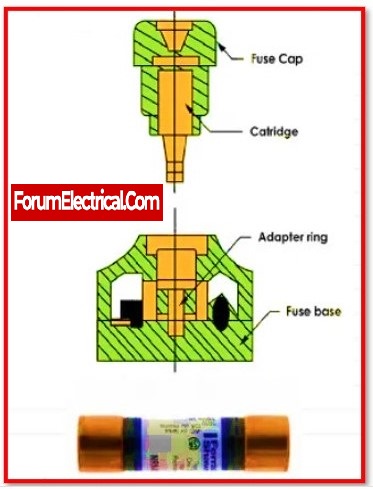

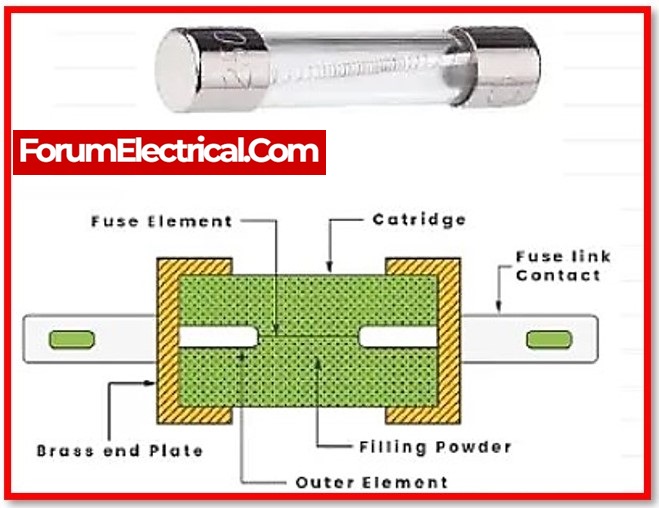

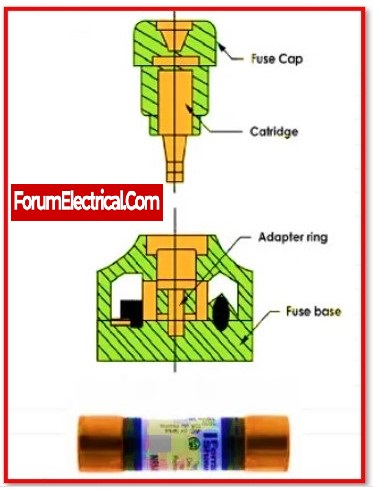

a). D-type Cartridge Fuse

This fuse is made up of the cartridge, fuse base, adapter ring, and cap. The fuse’s base is made up of a fuse cap that is packed with the fuse ingredient by cartridge via an adapter ring.

It’s made up of the cartridge, fuse base, cap, and adapter ring. The fuse base contains the fuse cap, which is fitted with the fuse element via the adapter ring. The circuit is completed when the tilt of the cartridge makes contact with the conductor.

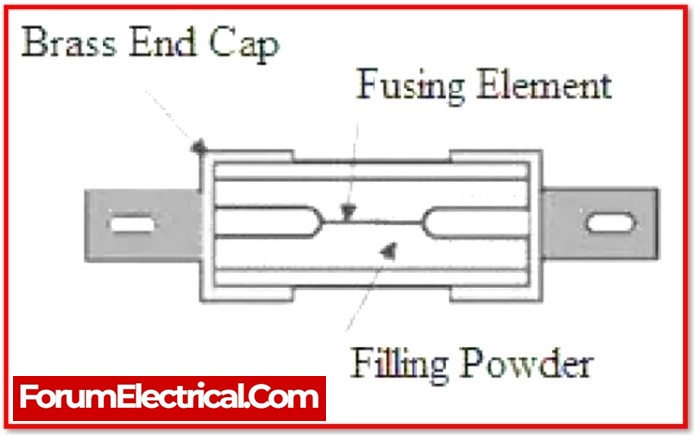

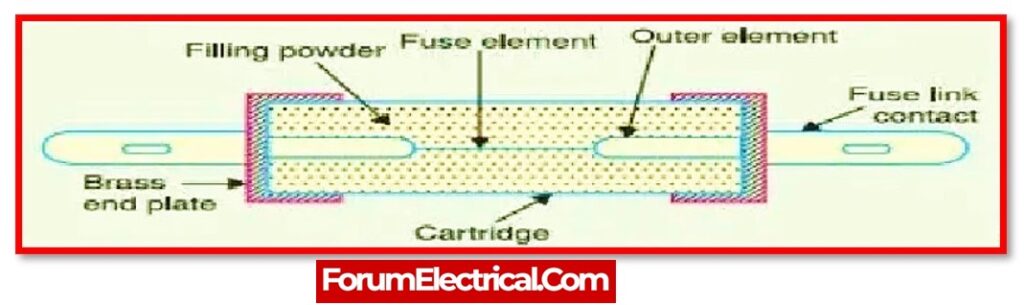

b). Link Type Fuse

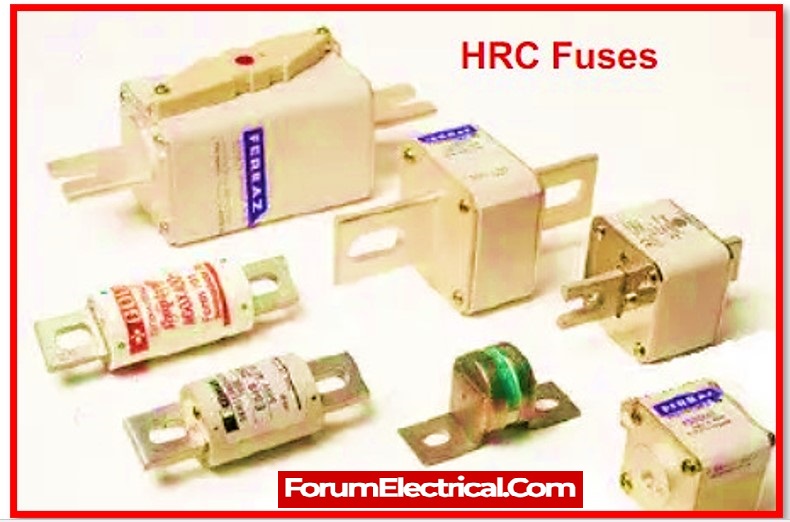

The link type fuse is also referred to as a high rupturing capacity (HRC) fuse or a BS type fuse. The current flow with the fuse element is specified under standard conditions in this type of fuse.

Under normal conditions, the flow of current by fuse element is given in this BS type fuse. The controlled arc generated by the blown fuse is made of porcelain, ceramic, and silver. The fuse element’s container is filled with silica sand. This type of fuse is divided into two parts: blade type and bolted type.

c). Blade and Bolted Types of Fuses

Plastic is used in the design of knife fuses and plug-in fuses. This type of fuse is easily replaceable in an electric circuit that is not loaded.

The conducting plates of a bolted type fuse are set to the fuse’s base.

3). Striker Types Fuse

The striker type of fuse is used to trip and close an electrical circuit. These fuses have a significant amount of force as well as displacement.

4). Switch Type Fuse

The switch type fuse is basically made up of a metal switch and a fuse. These fuses are mostly used at low and intermediate voltages.

5). Dropout Types of Fuses

Fuse melting in this fuse type causes the element to fall below gravity due to its minimal assistance. These types of fuses are used to protect external transformers.

HV- High Voltage Types of Fuses

HV fuses are commonly used to protect transformers such as instrument transformers, small power transformers, and power systems. Normally, these fuses are charged for voltages ranging from 1500V to 138000V.

In order to provide consistent and steady performance, the fused part in HV fuses is made of copper, silver, or in some cases, tin. These fuses are divided into three types, which are as follows.

1). Cartridge Type HRC Fuse

The fuse component of the HRC is cut in the helix form, which avoids the corona effect at higher voltages. It consists of two fused elements, low resistance and high resistance, which are located parallel to each other.

The low-resistance wires take the blown-out current and reduce the short-circuit current throughout the fault state.

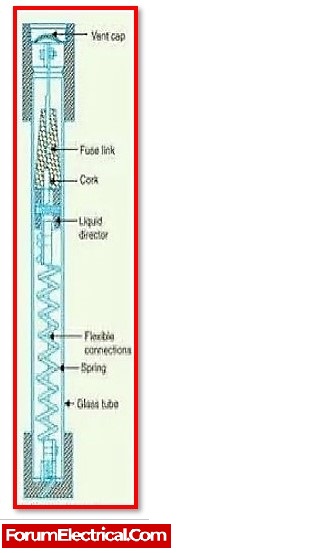

2). Liquid Type HRC Fuse

This fuse is packed with carbon tetrachloride, which is also preserved at the tops of both caps.

The error occurs when the flowing current exceeds the allowable limit, and the fuse element is blown out. For HRC fuse types, the fuse fluid acts as an arc extinguishing standard.

They can be used to protect the transformer as well as the breaker circuit’s support protection.

3). Expulsion HV Types of Fuses

Because they are inexpensive, these fuses are widely used to protect feeders and transformers.

It is rated for 11kV and has a cracking capacity of up to 250 MVA. This fuse has an unfilled open-finished cylinder made of synthetic resin-bonded paper.

The fuse elements are placed in the cylinder, and the tops of the tubes are connected to appropriate equipment at each end.

The arc is blown off in the cylinder’s inner covering, and the gases formed as a result destroy the arc.

Advantages of the Fuse

- It is inexpensive and requires no additional care or maintenance.

- The devices are entirely automotive fuses and require far less time than circuit breakers.

- Because fuses are available in smaller sizes, they have a current-restricting effect in abnormal conditions.

- The device’s reversible time-current features allow it to be used for overload protection.

Disadvantages of the Fuse

- It takes some time during the fuse replacement process.

- The time-current feature will not always be in sync with the safeguarding element.

Application of the Fuses

Electrical and electronic fuses of various types can be used in a wide range of electrical and electronic systems and applications, including:

- Transformers and motors

- Air-conditions

- Home distribution systems

- Electrical appliances and devices

- Laptops

- Mobile phones

- System of games

- Printers

- Cameras with digital sensors

- DVD recorders

- Electronics that can be carried around

- LCD displays

- Scanners

- Packs of batteries

- Hard disc drives (HDDs)

- Converters