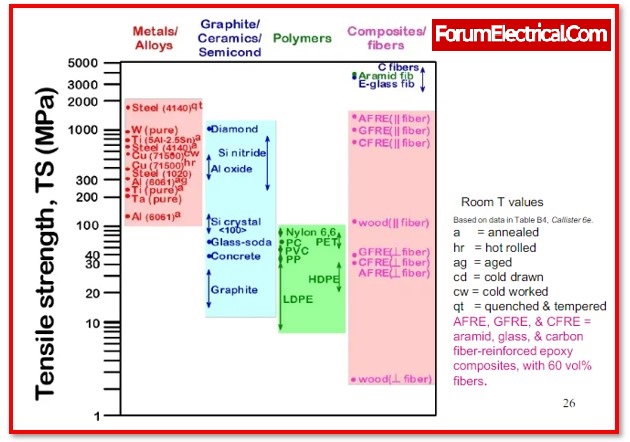

- 1). Strength

- 2). Toughness

- 3). Hardness

- 4). Hardenability

- 5). Brittleness

- 6). Malleability

- 7). Ductility

- 8). Creep and Slip

- 9). Resilience

- 10). Fatigue

- 11). Elasticity

- 12). Proportional limit

- 13). Elastic limit

- 14). Yield point

- 15). Stiffness

- 16). Plasticity

- 17). Formability

- 18). Castability

- 19). Weldability

- 20). Thermal conductivity

- 21). Electrical resistivity

- 22). Electrical conductivity

- Frequently Asked Questions (FAQ)

It is essential to have a thorough understanding of the mechanical characteristics of the material before converting the material into its final form for use in an engineering products or application. The mechanical properties of the material are those characteristics that influence the material’s capacity for mechanical strength as well as its capacity to be moulded into an appropriate form. The following is a list of some of the usual mechanical characteristics of a material:

1). Strength

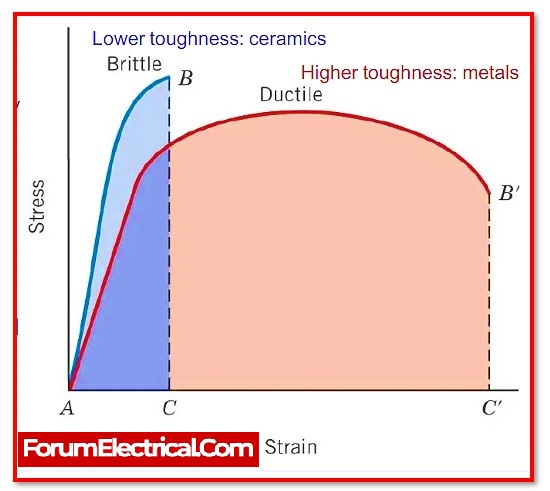

2). Toughness

3). Hardness

4). Hardenability

5). Brittleness

6). Malleability

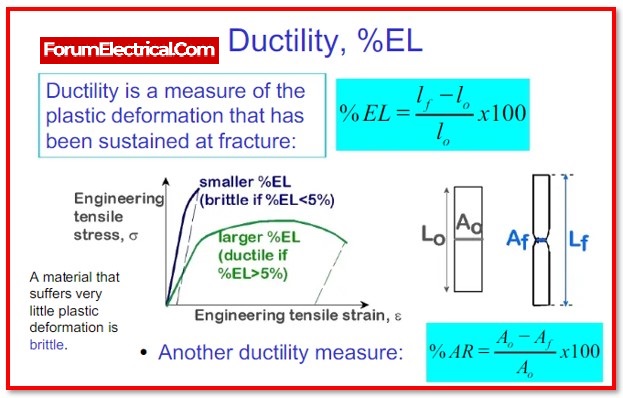

7). Ductility

8). Creep and Slip

9). Resilience

10). Fatigue

11). Elasticity

12). Proportional limit

13). Elastic limit

14). Yield point

15). Stiffness

16). Plasticity

17). Formability

18). Castability

19). Weldability

20). Thermal conductivity

21). Electrical resistivity

22). Electrical conductivity

1). Strength

Strength is the quality of a material that prevents the substance from deforming or breaking down when subjected to external pressures or stress. The materials that use in the completion of engineering supplies need to have sufficient mechanical strength in order to be able to function normally under a variety of mechanical loads and stresses.

2). Toughness

Toughness refers to a material’s capacity to take in energy and change shape plastically without breaking apart. Tough materials can withstand high levels of stress without becoming brittle. The quantity of energy contained inside a certain volume serves as the basis for its numerical value. Its unit is the Joule/m3. Characteristics of a material’s response to stress and strain may be used to estimate the value of the material’s toughness. The combination of a high strength rating and a high degree of ductility that gives materials their toughness.

3). Hardness

The capacity of a substance to withstand external stress without permanently altering its form is referred to as its hardness.

- Scratch Hardness,

- Indentation Hardness, and

- Rebound Hardness

are some of the different methods that hardness may be measured.

a). Scratch Hardness

The capacity of a material to resist the scratching of its outer surface layer by a force from the outside is referred to as its scratch hardness.

b). Indentation Hardness

It is the capacity of materials to resist the denting that occurs as a result of the punch of external hard & sharp objects.

c). Rebound Hardness

The method known as rebound hardness may also be referred to as dynamic hardness. The height of the “bounce” of a diamond-tipped hammer after it has been dropped from a certain height on the material is used to determine it.

4). Hardenability

5). Brittleness

When a material is exposed to a force (or) load, brittleness refers to the way quickly the material fractures under the influence of the stress. When a brittle material is exposed to a stress, the material will experience relatively little energy and will shatter without experiencing considerable strain. On the other end of the material spectrum from ductility is brittleness. The brittleness of a material changes depending on the temperature. When cooled to temperatures lower their ductile operating range, many metals experience brittle.

6). Malleability

The capacity of a solid material to be readily deformed under the compressive stress is referred to as its malleability. This characteristic of solid materials indicates that easily a material may be deformed. The capacity of a material to be flattened down into a thin sheet via the use of hammering or rolling is one of the most common criteria used to classify malleability. This flexibility of material has this mechanical feature as one of its characteristics. The pliability of a substance is directly proportional to its temperature. The degree to which a material may be bent or shaped improves as the temperature rises.

7). Ductility

A solid substance is said to have dctility if it can be readily deformed when subjected to tensile stress. This property provides that easily a material can be distorted. When evaluating a material’s ductility, it is often referred to in terms of its capacity to be drawn or pulled into a wire.

This mechanical characteristic is also an element of the material’s flexibility, and its way of functioning changes depending on the temperature. The ductility of the material tends to increase in proportion to the temperature.

8). Creep and Slip

Creep is a feature of a material that describes its tendency to move slowly & change shape forever when subjected to mechanical force from the outside. It happens when the body is exposed to big mechanical stresses from the outside for a long time. When an element is heated for a long time, it causes more serious creep. Slip-in material is a flat surface with a lot of atoms in it.

9). Resilience

When a material is stressed and elastically deformed, it has the capacity to absorb energy and release it when the tension is removed. The highest amount of energy that may be absorbed without causing irreversible deformation is referred to as resilience. The highest amount of energy that may be absorbed per unit volume without permanently deforming anything is known as the modulus of resilience. By integrating stress-strain curve from zero to the elastic limit, it may be calculated. It measures in joule/m3.

10). Fatigue

Fatigue is the weakening of a material caused due to repetitive stress. At grain boundaries and interfaces, tiny fractures start to develop when a material is exposed to cyclic loading and loading that is over a threshold value but significantly below the material’s strength . Subsequently, the fracture expands to a catastrophic size. The structure becomes shattered because the crack spreads quickly. The structure’s form has a significant impact on fatigue. Where the fatigue fracture initially appears, square holes and pointed corners provide higher strains.

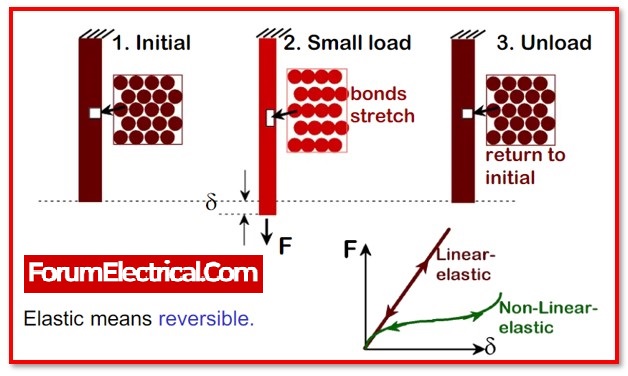

11). Elasticity

Elasticity is the ability of a material to return to its original shape after being deformed by the application of external forces and then to retain that shape when those forces are removed.

It is also referred to as the ability of the material to return the original position after being deformed when the load or stress is removed from it. The tensile property of material is another name for this component of the material.

12). Proportional limit

A material is said to have reached its proportional limit when it was subjected to the highest possible stress and yet managed to keep its rate of strain to the stress completely uniform.

Despite considering that it is difficult to determine its significance, it has a number of essential uses, including the construction of specific instruments, springs, and other things.

13). Elastic limit

It is possible to stress many metals to a degree that is slightly greater than their proportionate limit without causing them to permanently set.

The elastic limit of a material is defined as the maximum stress that it can withstand before it begins to exhibit some kind of permanent set. When this limit is exceeded, the metal will no longer return to its former shape, & the permanent set will effect.

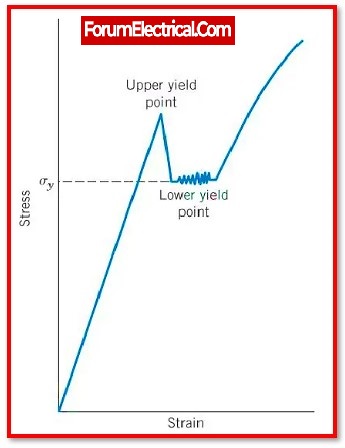

14). Yield point

When subjected to a given stress, ductile metals fail to provide any resistance to the tensile forces acting on them. This indicates that the metals flow, and a rather considerable permanent set takes place, even if the load has not much increased. This particular moment is referred to as the yield point.

A specific yield point may be seen in some metals, such as mild steel; in this instance, the yield stress simply refers to the stress at this point.

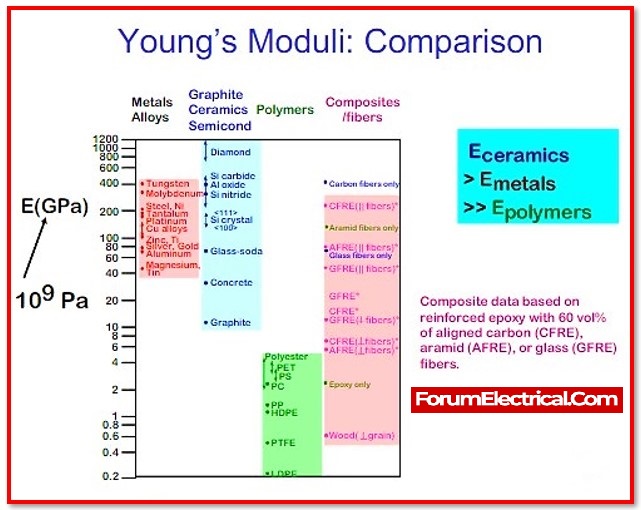

15). Stiffness

The capacity of material to resist the deformation when subjected to stress is the meaning of Stiffness. Stiffness or rigidity refers to the resistance of a material to elastic deformation or deflection, and the term may be used interchangeably.

The level of rigidity may be determined by calculating the modulus of elasticity.

A high degree of stiffness (or) rigidity is possessed by a substance that, when subjected to stress, exhibits very little or no discernible deformation at all. For example, suspended beams made of steel and aluminium may both be capable of carrying the necessary weight, but the aluminium beam will “sag” or deflect more than the steel beam.

That determines that the steel beam has a greater degree of stiffness or rigidity than an aluminium beam. If the material exhibits an elastic behaviour with a linear stress-strain connection in accordance with Hooks law, the Young’s modulus of elasticity (E) is used to quantify the material’s level of stiffness.

The value of Young’s modulus indicates the stiffness that a material is, hence a larger number indicates a stiffer material. In tensile & compressive stress, it is referred to as the modulus of stiffness or “modulus of elasticity.” In stress, it is termed the modulus of rigidity, and for frequently used materials, this is typically 40% of the value of Young’s modulus.

16). Plasticity

The mechanical property of the material known as plasticity is defined as the ability of the material to permanently maintain the deformation that was generated under stress. In order to effectively forge, stamp pictures into coins, and create decorative work, the material must possess this quality.

It is the capacity or propensity of the material to go through some degree of persistent deformation without rupturing or failing in the process. Only when the elastic range of the material has been surpassed does the material start exhibiting plastic deformation.

This feature of a material is crucial in forming, shaping, extruding, & many other types of other procedures that involve either hot or cold working. At room temperature, materials like clay and lead, among others, have a plastic consistency, and steel has a plastic consistency when it is forged. This characteristic tends to become stronger as the temperature of the substance in question increases.

17). Formability

The ability with which metals may be shaped and moulded into a wide variety of configurations and dimensions is a characteristic of the material. The crystal structure of metal, the grain size of the metal after hot and cold working, and the presence of alloying elements in the parent metal are the several aspects that contribute to the formability of the metal.

Metals with tiny grain sizes are appropriate for shallow forming, while metals with larger grain sizes are appropriate for heavy forming. The use of heat improves formability. The capacity to be formed into various shapes is possessed by low-carbon steel.

18). Castability

Castability is a feature of metal that illustrates the ease with which it may be cast into a variety of shapes and sizes. Castability is also known as castability. Cast iron, aluminium, and brass all have an excellent castability due to their properties.

19). Weldability

Weldability is the quality of a metal that shows that two comparable or different metals may be united by fusion, either with (or) without the application of pressure, and either with or without the use of filler metal (welding).

Iron, steel, cast steels, and stainless steels are the decreasingly weldable types of metals. Stainless steels are the least weldable.

20). Thermal conductivity

Thermal conductivity refers to the capacity of the substance to carry heat energy from one point to another.

21). Electrical resistivity

The resistance of the material to transfer of electricity through it is a quality that may be linked to that material.

22). Electrical conductivity

It is the quality of a material that determines whether it permits the flow of the electricity through it.

Frequently Asked Questions (FAQ)

a). What is material creep failure?

Creep is a material property that describes a material’s propensity to move slowly and irreversibly distort when exposed to external mechanical pressures. It occurs as a result of extended exposure to considerable external mechanical stress within the yielding limits. Creep is severe in materials that have been exposed to the heat for lengthy period of time. Although it may occur at normal temperature, this deformation is more common at high temperatures.

b). When loads are applied, what factors that affect the mechanical characteristics of engineering materials?

- The quantity of alloy,

- Form,

- Grain size,

- Imperfection and

- Flaws,

and other elements all have an impact on the mechanical characteristics of engineering materials. The composition of an alloy can increase (or) decrease the hardness and strength of a material. Smaller grain sizes improve material strength. Imperfections and flaws reduce the material’s strength. However, form has no or very little effect on the material.

c). How does temperature impact the mechanical characteristics of engineering materials?

The temperature has an effect on the strength of a material. The elasticity of the material varies with temperature. At higher temperatures, the material turns ductile, whereas at lower temperatures, the material turns brittle. As a result, the strength varies with temperature.