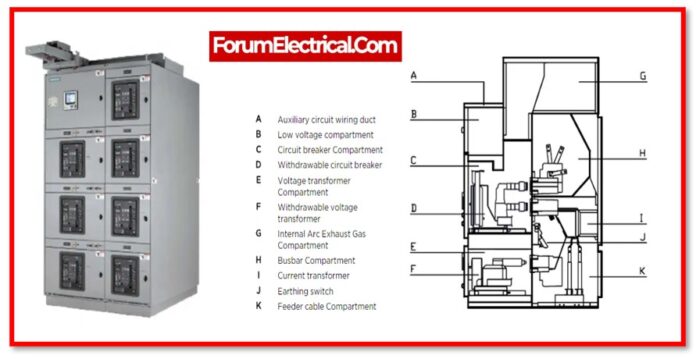

A cubicle switchboard is a specialised equipment unit used to receive and distribute power.

- Connecting devices,

- Connecting buses,

- Collecting buses,

- Measurement devices,

- Relay protection, and

- Automation devices

are all part of it.

Cubicle switchboards can be used both indoors & outdoors.

For the electrical distribution system to be safe, dependable, and functioning, low voltage cubicle switchboards must be tested and inspected. Nearly all of the time, these inspections and tests are done throughout the production process, during installation, & as part of routine maintenance.

The subsequent post provided the stipulations for the inspection & testing procedures that were necessary for LVSB installation.

Visual Inspection

Visual inspection shall be performed to ensure that the LVSB Installation is properly installed in compliance with the specification. The following elements must be included:

- Type-tested assembly construction

- Main busbars and droppers/risers

- Air circuit breakers/fuse switches

- Power factor (P.F) correction capacitor bank

- Harmonic filter

- Automatic Changeover Switch

- Instrumentation and protection devices

- incoming/outgoing busbars and cables

- Portable earthing equipment

- Operating handles/keys

Site Inspection before Incoming Supply Connection

Following the completion of the LVSB installation and prior to the connection of incoming supply cable, the following tests are required to be carried out on site:

1). Dielectric Test

In order to validate the LVSB’s dielectric qualities, an appropriate dielectric test needs to be carried out. IEC 60439-1 is the standard that must be followed for the test requirements.

2). Insulation Test

This is to be performed using an insulation tester capable of measuring 1000V or another device with comparable capabilities.

3). Secondary Injection Test

This is to be done with alternating current, and it is to check (roughly) that the protective relays or devices function in line with their performance curves by doing a test at the lowest setting, followed by two additional tests of current and timing. This is to be done three times.

4). Primary Injection Test

This is a concept that needs to be done in order to demonstrate that protective devices or systems function properly when set to the agreed-upon setting.

5). Polarity Check for Current Transformer (C.T.)

This needs to be done to make sure that all components of C.T. are connected in the appropriate manner.

6). Functional Test of All Devices

This must be done to make sure that all of the devices can function appropriately and as they were designed to.

- All circuit breakers,

- Isolating switches,

- Changeover switches,

- Contactors,

- Interlocking facilities,

- Protection relays,

- Earth leakage tripping devices,

- Metering facilities, and

- Instruments

are required to be tested as part of the equipment that is to be inspected.

7). Contact Resistance Test

This is to be done with a “Ductor” tester or a similar instrument to verify that the contacts & joints for switchgears, cables, and busbars, in addition to the contacts and joints for outgoing cables and busbars, are kept in good condition. This is to be carried out to ensure that the contacts and joints for outgoing cables and busbars are maintained in good condition.

8). Temperature Rise Limits Test

This should be done in accordance with the standards outlined in IEC 60439-1.

Due to the limitations created by the site, the primary injection test & the temperature rise limits test may both be executed in the plant if they receive prior approval from the PBSE.

Site Inspection after Incoming Supply Connection

After connecting the incoming supply cables and successfully commissioning the “Switchboard” on no load, the following tests must be performed.

- Voltage test from phase to phase

- Voltage test from phase to neutral

- Voltage test from phase to earth

- Voltage test from neutral to earth

- Phase sequence test on every incoming circuit.

Preparatory Procedures for Power Energization

Prior to power energization, the following must be inspected:

| Preparatory Procedure | Inspection Report | |

| The tightness of the bolts and nuts in the main & sub-main switch connections for the busbar chambers | OK | NOT OK |

| Earthing connections at all switches, compartments, and earth electrodes | OK | NOT OK |

| Removing erroneous (damaged) bare conductors from switches, air circuit breakers (ACB), and switch cubicles where they may come into direct touch with live parts or be in any way susceptible to such contact | REMOVED | NOT REMOVED |

| The phase order of all switches, their polarity, and any applicable fuse ratings | OK | NOT OK |

| The operation of the shunt trip mechanism and the stand-by battery supply | OPERATIONAL | NOT OPERATIONAL |

| Settings for the current transformer (C.T.) polarity, earth fault relays, and overcurrent protection | FUNTIONAL | FAULT |

| Switches and ACBs can be clean with a vacuum. | OK | NOT OK |

| Presence of hazard and Caution indicators. | OK | NOT OK |

| A certified certificate of completion of the work in accordance with COP Code 19. | CERTIFIED | NOT CERTIFIED |

Power Initialization Procedure

Retesting of the insulating resistance is necessary whenever there is an interruption in the switch-on process, such as the following day. The switch-on process must adhere to the following procedures:

- Turn on the main switch/ACB while turning off all other sub-main switches

- If everything is normal, turn on each sub-main switch individually while leaving the other outgoing switches off

- If everything is normal, turn on each individual outgoing switch one at a time

- Check whether there are any fault indications by monitoring the disc of the overcurrent (o/c) and earth fault protection relays for any change in position for IDMT relays (or) for digital protection relays

- Keep watch for around 30 minutes to listen for any strange noises or smells.

Review of the Documentation

Conduct a thorough review and check to ensure that all of the documentation, such as manuals, drawings, and wiring diagrams, is accurate & up to date.

Verifications of Safety

Make sure that all of the safety measures, such as the emergency stops and the interlocks, are operating as they intended.

Check to see that the relevant cautionary labels and signage have been affixed.

When performing these tests and inspections, it is absolutely necessary to adhere to the norms and rules that are prevalent in the sector. In addition, low voltage switchboards need to be maintained and tested on a regular basis to ensure that they continue to operate in a manner that is both safe and reliable.

Always undertake these tests and inspections under the supervision of certified electrical engineers and technicians, and be sure to take into consideration any local electrical codes and laws that may be applicable.