Current is often measured directly using a data acquisition (DAQ) device.

DAQ devices that measure voltage, on the other end, are frequently more easily accessible to the user.

This method necessitates converting the current to voltage in order for the voltage DAQ device to read the signal.

This can be accomplished with an electrical shunt, but it needs a system having a high input impedance. Calculations using established formulas are also required to determine the optimal shunt to use.

Input Impedance

Electrical impedance is a measurement of a circuit’s resistance to current if a voltage is connected to it.

A source network’s input impedance network, which includes both

- Static &

- Dynamic opposition.

Electrical opposition is more often recognized as reactance than static opposition.

A load network is the component of an electrical network which utilizes electricity, whereas a transmission network is the section that transmits power.

The output impedance of the source network and the input impedance of the load network govern how power is transported from the source to load network.

Impedance is frequently used to assess a network’s electrical efficiency, which is normally the ratio of useable power output to typically requires segmenting the network and determining both the input and the output impedance between the segments.

Efficiency is defined as the ratio of input impedance to total impedance, that is, the sum of input and output impedance.

For AC circuits, the reactance component of impedance frequently causes large power losses. Because of these losses, the circuit’s current may be out of phase with its voltage.

Because, power is a combination of both voltage and current, the power delivered across the circuit is less than if the voltage were in phase.

DC circuits do not have reactance and so do not suffer from it.

Data Acquisition Systems

DAQ refers to the method of sampling electrical signals, which are often used to measure physical conditions.

- Sensors,

- Signal conditioning circuitry, and

- An analog-to-convert physical characteristics into an analog signal

are among the three components.

The signal-conditioning circuitry turns signals into digital values that can be transformed. The digital values are subsequently converted via an analog-to-digital converter. Data loggers are the most common name for standalone DAQ systems.

Low input impedance data recorders normally have an input impedance of around 22kΩ. With a high input impedance, it must have an input impedance of a minimum of 100 M, unit cost.

This type of data logger also has an analog-to-digital (successive approximation) converter. It should also include eight single-ended channels with independent A/D on voltage inputs of 1V, 2V, 5V, and 10V.

Electrical Shunt

An electrical shunt is an instrument that uses a low-resistance path to carry electricity around a circuit’s point.

An ammeter may determine current that is too big for it to accurately measure directly by using one of the numerous conceivable ammeter shunts.

This type of accurately known resistance is relatively minimal in comparison to the load circuit current. To pass through it, the shunt is connected in series with it.

The voltage drop (VD) across the shunt may then be measured by connecting a voltmeter to either end of the shunt. the resistance of the shunt and this voltage drop may then be computed.

The voltage drops at the shunt’s maximum current, which must be derated after the device has been in operation for a predetermined period of time, is the value that distinguishes a shunt and is commonly 50 mV, 75 mV, or 100 mV.

Shunts frequently have a de-rating for minutes of continuous usage. The resistance of a shunt might deviate from its specifications as well as from its temperature and thermal drift. At 80 °C (176 °F), shunts often start to undergo thermal drift and suffer irreparable damage.

Calculations

The standard formula for determining current in a circuit is

I = V/R

Where,

V – Voltage (V)

I – Current (Amps) and

R – Resistance (Ω)

In a shunt, the resistance is equal to the rated resistance of the device, and the voltage is equal to the voltage difference between the Vin+ and Vin- input terminals of the voltmeter.

Ensure that the voltage drop stays within a certain range is the most important step in this process. An adequate signal-to-noise ratio often requires a minimum loss of several volts.

If the current source is separate from the ground terminal, noise can be reduced by connecting a 1kΩ resistor between the Vin-& ground terminals.

The current source’s maximum rated output voltage cannot be exceeded by the drop, yet it cannot be that much larger overall.

The voltage drop needs to be minimal enough to prevent the resistor from overheating and experiencing a considerable change in resistance.

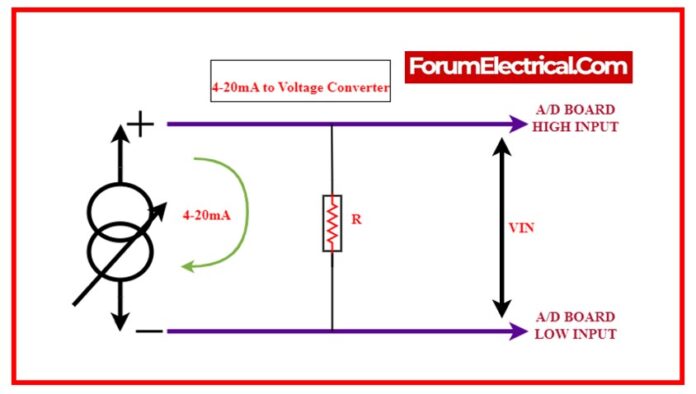

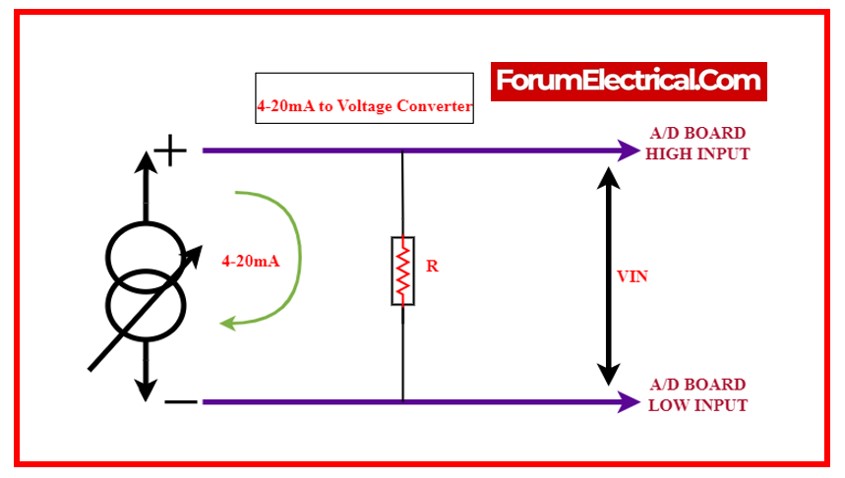

Measurement of 4–20 mA Input using Voltage Input Device

With a voltage-only instrument, measuring 4 to 20 mA is easy and cheap.

Many A/D boards cannot directly take 4 to 20 mA signals. This problem can be solved in minutes. determine the resistor value to convert 4–20 mA to voltage.

For data acquisition systems & analog measuring equipment, the most often used resistor value is 250Ω, which generates a 1 to 5 VDC signal with 4 to 20 mA flow.

The following example shows how to choose the right resistor for any type of voltage input beyond 0 to 5 VDC.

Example-1: Suppose that 4 to 20 mA will be measured from an input of 0 to 2 VDC.

From Ohm’s Law,

R=2V/0.020A = 100Ω

- A 100 resistor can drop 2 volts when 20 mA is applied to it.

- A 100 resistor will drop by 0.4 volts when 4 mA is applied.

Thus, 4 to 20 mA across a 100 resistor will result in a 0.4 drop.

Another important consideration is that the tolerance of the resistor should be 1% or less, preferably 0.1%, as inaccuracies in the voltage drop.

A resister that changes significantly with time (or) temperature is not that want since it could affect accuracy.

To compensate for any differences in resistor value, must validate readings and make necessary fine-tuning changes in software.

Example-2: A 100 resistance may actually be 99.5Ω, therefore the voltage output will be 0.398 to 1.99V.

Simply connect the resistor across the voltage input terminals of the data acquisition system, & then connect two terminals.

This will cause a voltage drop that will be measured by the data acquisition as the current flows through the resistor.

If using the power supply to run a transmitter or a 2-wire sensor, it is also also need to ground the power supply.