Selection of Circuit Breaker

The procedure of selecting a circuit breaker is an important aspect of assuring electrical safety & efficient system performance. It includes a thorough study of various parameters to find the best circuit breaker for a certain application.

Circuit breakers should be selected based on specific usage requirements, such as the category of use, rated current, rated working voltage, & trip unit set current, among others.

When choosing a circuit breaker, several factors must be considered, including

- Voltage,

- Frequency,

- Interrupting capacity,

- Continuous current rating,

- Specific working conditions and

- Quality testing.

This article will guide you through the process of selecting a suitable circuit breaker based on your unique application.

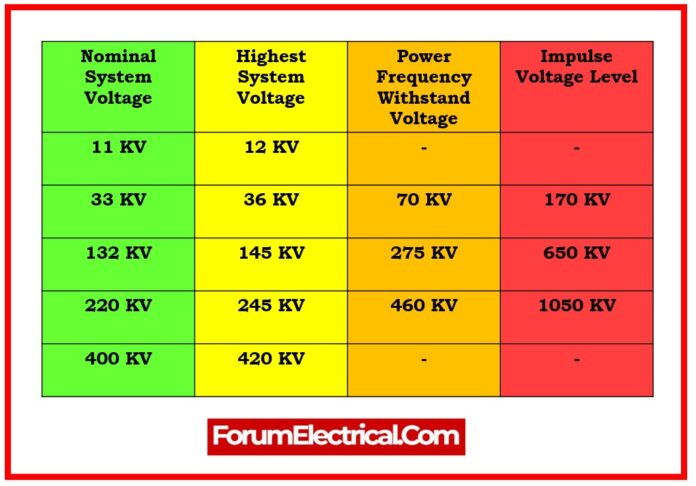

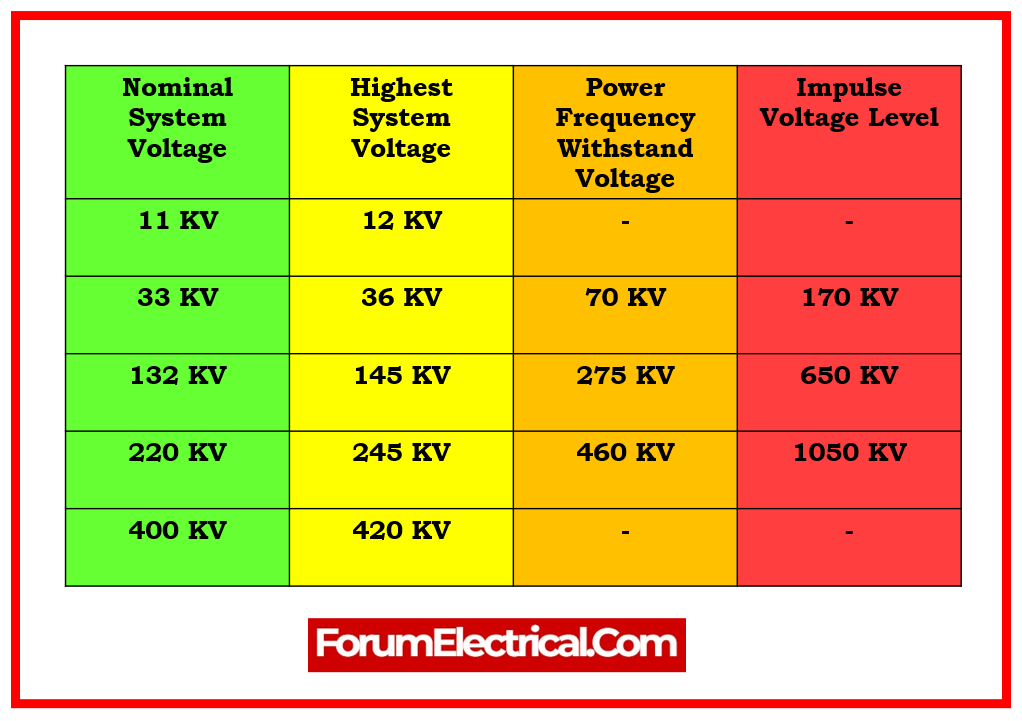

Guideline-1: Voltage Rating

Circuit breakers are available in a variety of sizes and configurations.

The highest voltage that may be applied over all end ports, the distribution type, and how the circuit breaker is completely integrated into the system all contribute to the overall voltage rating.

It is essential to choose a circuit breaker with sufficient voltage capacity that corresponds to the end application.

Guideline-2: Frequency

Circuit breakers with capacities of up to 600 A are capable of being used at frequencies ranging from 50 to 120 hertz.

Greater than 120 Hz frequencies can trigger the breaker to degrade. Eddy currents and iron losses generate more heating within the thermal trip components during higher frequency applications, necessitating the breaker to be derated (or) specifically calibrated.

The overall amount of deration is determined by the

- Ampere Rating,

- Frame Size, and

- Current Frequency.

As a general rule, the bigger the ampere rating in a certain frame size, the greater the derating required.

All breakers with ratings greater than 600 amps feature a transformer-heated bimetal & are only appropriate for 60 Hz AC.

Special calibration for 50 Hz AC minimal applications is commonly provided. Solid-state trip breakers are factory-calibrated for 50 or 60 Hz applications. The frequency of a diesel generator operation will be either 50 Hz or 60 Hz.

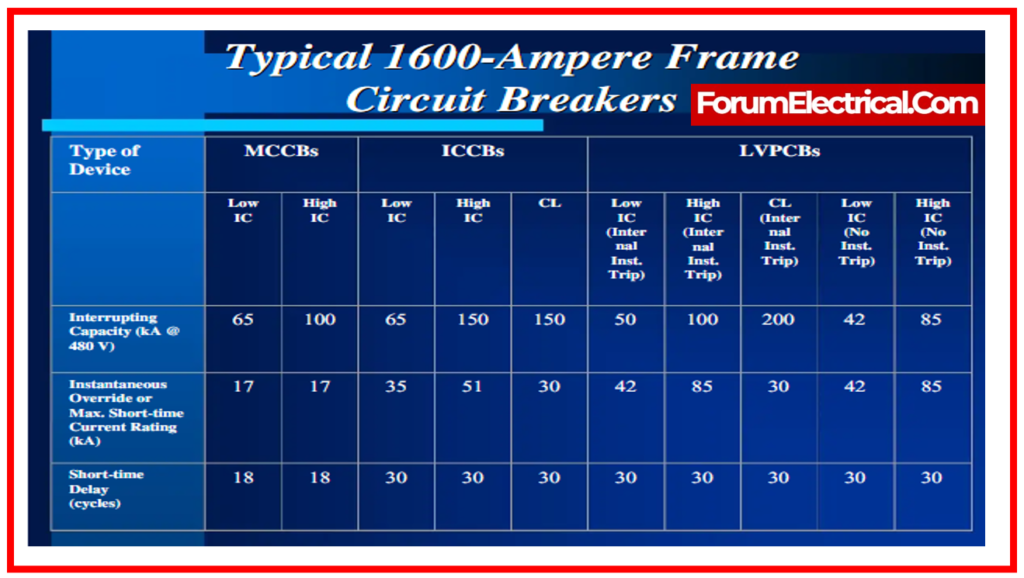

Guideline-3: Maximum Interrupting Capacity

It is commonly acknowledged that the breaker control panel can handle a fault current no higher than the interrupting rating. Interrupting a circuit breaker does not automatically cause the system to fail. At any given moment, it is possible to compute the maximum fault current that a system can supply.

When installing a circuit breaker, there is one hard and fast rule:

- The breaker’s interrupting capacity must be at least double the fault current that will be provided at the location of the breaker.

- If the amount of interrupting capacity is not applied correctly, the breaker could be damaged.

Guideline-4: Current Rating

At a certain temperature, molded-case circuit breakers have a continuous current rating in amperes. At the temperature at which it was measured, this ampere rating represents the continuous current that the breaker is capable of carrying. Manufacturers of standard circuit breakers typically calibrate their products at 104° F.

In a typical application, the ampere rating is totally dependent on the load type and duty cycle.

The main source for information regarding load cycles in electrical contracting sector is the National Electrical Code (NEC), which governs ampere rating.

A circuit breaker rated according to the conductor current carrying capacity is typically required for lighting and feeder circuits, for instance. Refer to NEC table 210.24 for a list of the permitted loads and standard circuit breaker current ratings for the conductors of varying sizes.

Guideline-5: Typical Operational Condition

Choose a circuit breaker based on end user location. Some breakers are better for serious conditions. When picking a circuit breaker, consider the following conditions:

At temperatures above 104° F, standard thermal magnetic breakers need to be derated (or) recalibrated. All breakers have been calibrated at 77° F for years, therefore those over it were derated. A special breaker was used since enclosures were usually 104° F. The mid-1960s industry standard required every standard breaker be checked and calibrated at 104° F.

Continuously moist breaker requires special treatment. This therapy prevents unit-eroding mold and fungus. Enclosed space heaters work in high humidity. Possible: remove the breakers from the corrosive areas. If this is unattainable, corrosion-resistant breakers exist.

Whenever mechanical shock is probable, a circuit breaker arrangement should have an anti-shock device. The trip bar is secured by inertia counterweights above the central pole under normal stress. This weight should allow thermal (or) magnetic trip units to work on overload or short circuits.

Above 6,000 feet, circuit breakers must meet current, voltage, & interrupting capacity requirements. Altitude air is thinner and transfers heat away from the current-carrying components less than denser air. In additional to overheating, thinner air slows dielectric charge development to withstand atmospheric pressure voltage. Altitude affects most generators & power producing equipment.

Breakers can be positioned horizontally (or) vertically without affecting tripping or interrupting capacity. Most breaker units are housed & on a swaying surface for severe winds. High winds could shatter a circuit breaker on inflexible surface.

Guideline-6: Tripping Unit

For circuit breakers, the “brain” is the trip unit, which takes readings of electrical current and other physical characteristics and determines when to “trip” the breaker, opening its mechanical contacts quickly.

In the case of a

- Ground fault,

- Thermal overload, or

- Short circuit,

the trip unit of a circuit breaker opens the contacts of the breaker automatically.

- Thermal-magnetic trip unit and

- Electronic trip unit

are the two different types of trip units.

Thermal-Magnetic Trip Unit

The bimetallic thermal device which opens the circuit breaker (CB) with a delay that depends on the size of the overcurrent is a part of a thermal-magnetic trip unit, which comprises moving parts. It also has a mechanism for activating the breaker by means of magnetic forces that are directly proportionate to the current passing through it. A strong magnetic field and high current flow from a short circuit, to put it simply. To activate the trip mechanism, this magnetic field is utilized.

Electronic Trip Unit

A circuit breaker’s electronic trip unit can be programmed to detect when the current is too high or too low and then trigger a trip signal.

Guideline-7: Maintenance & Testing

Maintenance

Enclosures prevent dirt, moisture, mold, dust, containments, and tampering. Terminal connections & trip units should be tightened to factory torque for proper maintenance.

These connections will weaken and need tightening.

Breakers need

- Regular cleaning.

- Loose terminations,

- Incorrect terminal conductors, and

- Improper cleaning can overheat & weaken the breaker.

Manual breakers only need clean contacts & free connections. Restarting rarely utilized circuit breakers refreshes systems.

Always contact a licensed electrician for generator circuit breaker selection.

Circuit breaker safety depends on site conditions, so only qualified professionals with licenses may recommend equipment.

Testing

UL Testing: All UL standard molded case circuit breakers are product and calibration tested to UL Standard 489. UL-certified breakers are factory-calibrated. The unbroken seal keeps the breaker calibrated, unchanged.

Field Testing: Field data usually differs from reported. Factory testing differed from field testing, influencing data. Tests at the factory ensure consistency. Temperature, altitude, climate control, and product-specific test equipment affect findings. NEMA AB4-1996 is a good infield test guide. The guide better represents infield testing results. Breakers may have testing instructions. If instructions are lacking, use an accredited circuit breaker service.