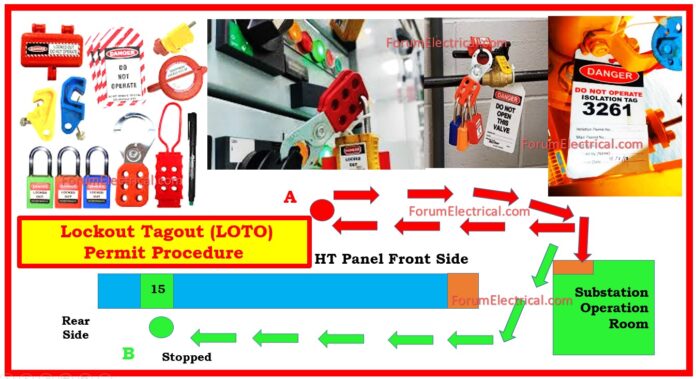

Lockout Tagout (LOTO) Permit Procedure

Lockout Tagout (LOTO) Permit Procedure goes over electrical safety precautions for working on the equipment, particularly lockout tagout (LOTO) permit requirements.

It specifies when LOTO permits are needed, which is when an unexpected starting, movement, or energy release may endanger personnel during maintenance.

It covers the four components of the LOTO permission system:

- Request,

- Isolation,

- Completion declaration, and

- Restoration.

Prior to starting work, it is essential to identify all energy sources, isolate and shut out energy isolation devices, & verify the zero energy state.

The guideline emphasizes that 100% compliance with LOTO procedures is essential for their safety.

When is a LOTO permit required?

When working on any electrically powered equipment, it is required to disconnect the electrical power to the equipment or system. In these cases, the Lockout Permit Procedure must be followed. If multiple organizations are using the same equipment, each must obtain its own ELP.

The primary reasons for Lockout Tagout Permit (Safety Work Permit) systems are:

- To prevent injury to users

- To prevent accidents, fires, and explosions that cause property damage.

- Isolate problematic equipment from the system.

Which Energy is Hazardous?

Under the correct conditions, any energy may be hazardous. This includes:

- Electrical: Electrical energy storage using capacitors and inductors.

- Pneumatic: Residual Pneumatic Pressure- Air Accumulator Tank

- Hydraulic: stored mechanical energy through spring tension or compression.

- Thermal: consisting of steam, hot water/liquid, and hot air

- Chemical: Heated liquid through a pipe line.

- Gravity: Stored gravitational energy with a large counterweight.

Energy can be released through several methods, including

- Cross-circuiting

- Reversed wiring.

- Unblocking

- Component failure

- Repositioning

- Separation

- Other people’s actions

- Leakage

- Turning off machines and equipment

does not ensure safety.

To operate safely on a machine or piece of equipment, bring it to a zero energy state. We employ Energy Isolating Devices that are appropriate for the specific energy type.

Which are EIDs?

- Switches, fuses, and circuit breakers are used for electrical power supply. Isolation valves are used for steam.

- Water and other liquids for valves.

- Machines can be powered by electricity or compressed air.

- Compressed air requires an isolation valve.

Each year, thousands of people are wounded or killed on work sites due to unanticipated energy releases.

- People often fail to isolate overall power while working with multiple sources.

- Even with the breaker turned off, some parts of the switchgear panel may still be live.

- This could be due to a lack of expertise or a rush to work.

- Employees who work on OH lines are victims of such incidents.

- Some individuals forget to discharge capacitors after turning them off.

- The unexpected release of charged energy might be quite harmful.

- Spring energy from a charged spring might crush the finger.

Electrical energy can be isolated by:

- Turning off every electrical energy source.

- Isolating the equipment’s electricity from external energy sources. (EID)

- Locking out the EIDs.

- Release stored energy from capacitors, breaker springs, and long cables.

- Test to ensure you have entered the Zero Energy State.

Sections in LOTO Permit System

The LOTO system consists of four sections, and the format for the Electrical Lockout Permit (ELP) may differ significantly between organizations.

Part A

If a contractor will be performing the work, their name should be included.

Fill out all necessary information, including equipment tag number, date and time, and cause for shutdown, carefully.

The operator-in-charge signs & agrees to discharge the equipment. He distributes the ELP form (in duplicate) together with Part A.

The permit is now transmitted to the substation to isolate power.

Part B

Part B requires the Electrical Shift-in-charge/technician to isolate electricity to the equipment listed in Part A of the permit.

Prior to obtaining the permit, the Operation Group must turn off the equipment.

The substation operator must fill out several forms.

Several companies use a padlock to secure modules, power switches, and ON-OFF control switches. Isolate power and remove fuses after powering off.

A lockout tag (‘DO NOT SWITCH ON’) is attached to the LT switch handle or operating switch (on door) of breaker panel. If there are interlocks, they will be checked to determine whether they should be isolated.

The date and hour of isolation are also noted in Part B. Finally, the electrical supervisor signs it.

Part C

Part C comprises a declaration of job completion.

The organization completing the job must certify that the work zone has been cleaned and that the equipment is safe to use.

This section requires the name & signature of the person who is returning the permission, as well as the area in charge.

Part D

The permission has now been forwarded to the substation for power distribution.

The electrical group is able to lift the lockout, but if another lockout permit is pending for this equipment, the power will not be turned on.

The field tag (returned by the organization with ELP) and the one attached to the switch, breakers, or LT switchgear will be compared.

Caution boards are removed after all points have been checked and cleared.

The equipment cannot be activated because another permission is pending for the identical equipment. If all permissions are approved, power is restored to the relevant equipment.

Where might LOTO errors occur?

- Incorrectly typed equipment tag number

- Unfilled (or) incomplete form boxes.

- The production group did not turn off equipment before transmitting the ELP to the substation.

- Isolation is not completed or the wrong component is isolated.

- The HT panel (or) MCC module door is not properly closed.

- Tags provided are not appropriately associated with the location/hardware required.

- Equipment is powered temporarily by lifting the LOTO permit.’

- Organizations working on the identical equipment do not require separate LOTO permits.

- After the LOTO permit is returned, several fuses are placed into the module.

Everyone should follow the LOTO method to ensure the plant’s safety. Many mishaps have happened owing to incomplete (or) non-compliance with LOTO procedures.

This system’s observance is also assessed during a safety audit.

Case Study: Accident on 11 KV Panel

Case Study

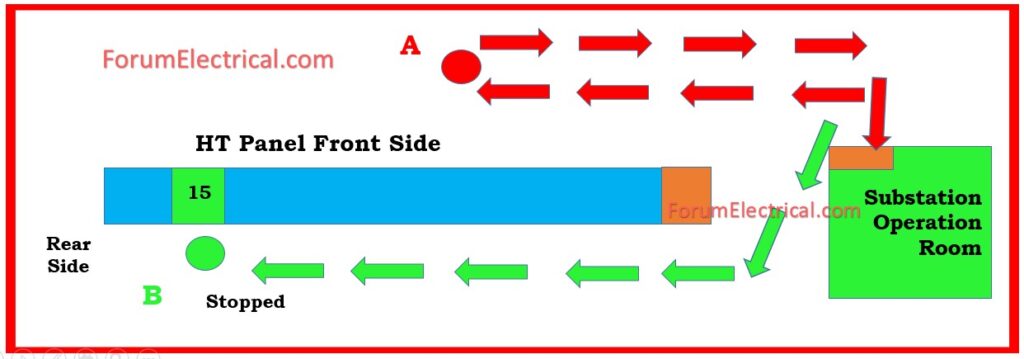

There were 11 KV panels in the substation. In a particular area, there was a shift operating room. Panel-15, which feeds Transformer Tr 02 (11KV/425 V), needed to be shut down.

After receiving the permit, A and B both left the room. (A was an operations technician, while B was a maintenance technician. B was working on rear side of Panel-15.

B gave A the LOTO form; to turn off the breaker for Panel-15, A exited the room and started moving towards it.

At the same moment, B commenced and moved to the back side of HT panels. He carried a tool kit with him.

B took out a ratchet spanner and began loosening the nuts on the rear cover of Panel-15.

Approximately four minutes passed. B removed twenty-two bolts (out of 26). He removed all 22 bolts.

He checked his danger watch: five minutes had elapsed.

He took an earth rod and connected one end of wire to the top of the rod.

He secured the other end with an earth strip that ran along the wall.

B believed that by now, A would have turned off the breaker. He opened the back cover.

He connected the rod’s active end to one HT wire lug. There was a significant flashover.

The HT breaker for Panel-15 tripped. B suffered severe burn injuries to his hands and forearm.

Case Analysis

During the investigation, A stated that he returned to the room after hearing the telephone ring. It was official communication.

Investigators checked & found the truth.

The investigator noted that A did not provide a signed LOTO permit following isolation.

Case Cause

- Quickly start of doing the work.

- Assumption

- Poor communication

- Safety concerns

- The LOP procedure was not completely followed prior to starting the work.

Action

Positive action in this accident is utilizing an earthing rod when working on 11 KV terminations.