What is Vacuum Circuit Breaker (VCB)?

In the high tension (HT) panel, this breaker is used to handle high voltage. It functions as a switching device, either manually or automatically.

- What is Vacuum Circuit Breaker (VCB)?

- Troubleshooting of Vacuum Circuit Breaker

- Identification of Problems in VCB

- Typical Faults in VCB

- 1). Spring charging motor moves continually

- 2). Breaker is in half-closed state

- 3). VCB slippage issue

- 4). VCB rack-in becomes extremely tight

- 5). Reduced vacuum bubble in VCB

- 6). VCB doesn’t open

- 7). Spring-operated energy storage circuit closure failure

- 8). Different opening & closing times – high bounce value

It is also employed to regulate and protect electrical systems from overloads and short circuits. Where the vacuum is employed for arc removal medium that breaker is known as a Vacuum Circuit Breaker.

It functions as air removal from contact-making & breaker chamber. Both fixed and movable contract is confined in a vacuum chamber.

The arc is extinguished using a high vacuum in chamber. The range of voltage comprises 11 KV to 33 KV.

Troubleshooting of Vacuum Circuit Breaker

Understanding how vacuum circuit breakers work is essential before starting any inspection or troubleshooting procedures.

In order to effectively extinguish electrical arcs, VCBs create a vacuum environment. Because of this special feature, VCBs can manage high-voltage applications without the need for intricate mechanisms or a lot of insulation.

Their key components are:

Vacuum Chamber: The area wherein the circuit is interrupted.

Insulating Materials: Insulating materials prevent electrical discharge beyond the circuit.

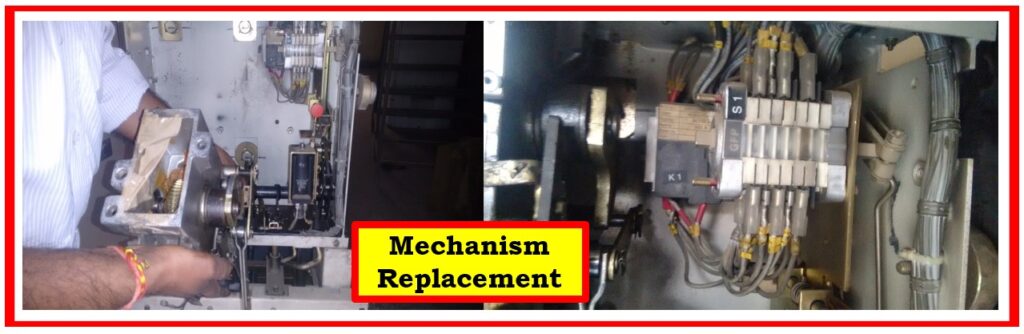

Operating Mechanism: The operating mechanism contains springs & levers that allow the breaker to open and close.

Given their important function, any malfunction can lead to major consequences, involving equipment damage & safety issues. Regular inspections are required to avoid such situations.

Certain high voltage (HV VCB) vacuum circuit breakers are of poor quality; the current carrying voltage is excessively high during operation, and some vacuum interrupters still leak air.

With the extensive application of vacuum circuit breaker (VCB), faults may occur from time to time.

In this post, we will explore the common faults of VCB breakers and their solution.

Identification of Problems in VCB

Circuit Breaker Not Closing; the following reasons may exist:

- Spring is not charged. Charge the spring physically or electrically.

- The closing coil can be faulty; replace the coil.

- Electrical shutting circuits are unhealthy; repair them.

- The auxiliary switch is not in good working order; examine and replace.

- The trip circuit is not healthy; solve the circuit problem.

- Breaker is not completely racked-in; ensure correct position.

- The master relay is in operation; reset it.

- The breaker is already in the ON position.

- Some mechanical issue.

- The emergency button has been pushed.

- The key was not turned properly.

Typical Faults in VCB

Because of their high reliability, long lifespan, and low maintenance requirements, vacuum circuit breakers (VCBs) are frequently used in medium-voltage applications.

However, like any electrical equipment, VCBs can malfunction while in use.

It is essential to identify and fix faults as soon as possible to ensure system reliability and prevent unscheduled outages. Some common faults:

- Spring charging motor moves continually.

- Breaker is in half-closed state.

- VCB handle is unable to insert

- VCB test (or) service position is not glowing.

- VCB slippage issue

- VCB rack-in becomes extremely tight.

- Door not closing

- VCB not tripping

- CB ON/OFF indication not lighting

- VCB arms moisturized

1). Spring charging motor moves continually

Causes:

- Damaged spring charging motor shaft pin

- Spring charging mechanism groove is damaged

- The charging mechanism’s misalignment

- VCB jammed in half closure position

Solution:

- Remove the ac fuse right away (or) trip the main AC MCB.

- Communicate to control room immediately

2). Breaker is in half-closed state

The interrupter may be damaged by sparking when the breaker jams in half closing, and there won’t be an LED to indicate whether it is ON or OFF.

Causes:

- The key was not correctly deleted, and a closure command was provided.

- The key was left inside the slot, and a closing command was sent.

- Closing spring mechanically misplaced due to loose fasteners.

Solution:

- Communicate to control room immediately

3). VCB slippage issue

Causes:

- The pole disparity exceeded the allowable limit of 2ms, causing the trip plunger to become stuck. 86 were picked up.

Solution:

- Communicate to control room immediately

4). VCB rack-in becomes extremely tight

Cause:

- Maybe the shutter action is tight.

- VCB can be misaligned.

- Tulip contact can be bent or scorched.

- Spindle groove is damaged.

Solution:

- Communicate to control room immediately.

5). Reduced vacuum bubble in VCB

Cause:

- Vacuum bubble material or manufacture is defective, and it leaks partially;

- The corrugated tube in vacuum bubble has material or manufacturing issues, causing leaks after repeated procedures;

- Due to the comparatively long distance of the operating link, split vacuum circuit breakers, such as those using electromagnetic operating mechanisms, directly affect the switch’s synchronization, bounce, over-travel, etc., accelerating vacuum reduction.

- Reducing the vacancy will severely reduce the vacuum circuit breaker’s capacity to break overcurrent and shorten its lifespan. Switches may explode in extreme instances.

Solution:

- The vacuum bubble must be qualitatively tested using a vacuum tester when the circuit breaker is frequently switched off for maintenance to guarantee a specified vacuum degree.

- Replace the vacuum bubble and perform stroke, synchronization, & bounce tests as vacuum lowers.

- Select vacuum circuit breakers from recognized manufacturers that are mature;

- Choose an integrated vacuum circuit breaker with the main body and operating mechanism.

- During inspection, operators should watch for discharge outside the circuit breaker vacuum bubble. If a discharge occurs, the vacuum bubble’s vacuum degree test result is unqualified, & the power must be replaced on time.

- To verify the circuit breaker is operating properly, power outage repair professionals must undertake typical tests such synchronization, bounce, travel, & over travel.

6). VCB doesn’t open

Cause:

- Remotely opening the circuit breaker is impossible.

- Not manually openable.

- Accidents activate relay protection, but circuit breaker can’t be detached.

- Broken opening coil.

- Reduced working power supply voltage.

- Opening coil resistance rises and force falls.

- Deformed opening ejector rod causes clogging and lower opening force;

- When opening, the ejector rod is significantly distorted and jammed.

- An accident will leapfrog and grow if the opening fails.

Solution:

- Check for opening circuit failure.

- Ensure the opening coil is disengaged.

- Check the opening coil resistance.

- Check the opening ejector rod for deformation.

- Ensure appropriate operational voltage.

- Replace copper opening mandrel with steel to prevent distortion.

7). Spring-operated energy storage circuit closure failure

Opening operation is not possible after closure; energy storage motor continues to work, causing coil overheating and damage.

Cause:

- The trip switch is placed lower, so the closing spring is not stored, the contact is converted, the motor power is switched off, and the spring energy is insufficient for opening operation.

- Travel switch installation is on the top side, so when the closure spring is charged, the travel switch contact (TSC) has not been converted, keeping the energy storage motor functioning.

- The energy storage motor cannot stop due to the broken travel switch.

- If the energy storage is not installed, if the line experiences an accident & the circuit breaker refuses to open, the accident will continue & develop.

- If the energy storage motor is broken, the vacuum switch may not be opened & closed.

Solution:

- Position the travel switch for precise motor power off.

- Travel switches should be replaced promptly if broken.

- To verify the circuit breaker’s good condition, the operator should monitor the closing energy storage indicator light during switching.

- The maintenance personnel should perform two opening and closing operations on the spot.

8). Different opening & closing times – high bounce value

Cause:

- Poor mechanical performance of circuit breaker body. Mechanical factors can cause large bounce values in different periods after multiple operations in split type circuit breakers.

- The distance across the operating rods causes deviations in the transmission of the opening force to the contacts, resulting in different periods and high bounce values.

- Changing the period or bounce will adversely impact the vacuum circuit breaker’s capacity to break the overcurrent, shorten its lifespan, and possibly cause it to explode. Hidden faults are more damaging.

Solution:

- To ensure stroke and overtravel, adjust the three-phase insulation rod length to achieve qualified synchronization & bounce test data. If adjustment fails, replace and readjust the vacuum bubble of the unqualified phase to the qualified data.

- Split VCB have many hidden failures, so when replacing one, use the integrated one and use the characteristic tester during regular maintenance to find and fix problems.

- To guarantee the vacuum circuit breaker’s safe and dependable performance, the equipment’s operating environment must be considered.