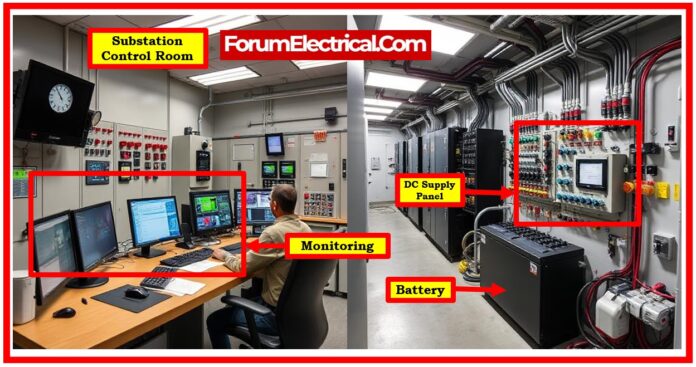

In any substation, the DC distribution system serves as the foundation for

- DC Power Supply System in Electrical Substation

- 7 Causes of DC System Failures

- 1). Battery Bank Failure

- 2). Charger Malfunction

- 3). Ground Faults in DC Circuits

- 4). Overloaded DC Circuits

- 5). Breaker (or) Fuse Failures in DC Panels

- 6). Loose (or) Corroded DC Connections

- 7). Communication Failures in DC Supervisory Systems

- Why is DC supply used in Substations?

- Which Protective System is needed for 110V DC supply constant monitoring?

- Conclusion

- Protection,

- Control, and

- Signaling.

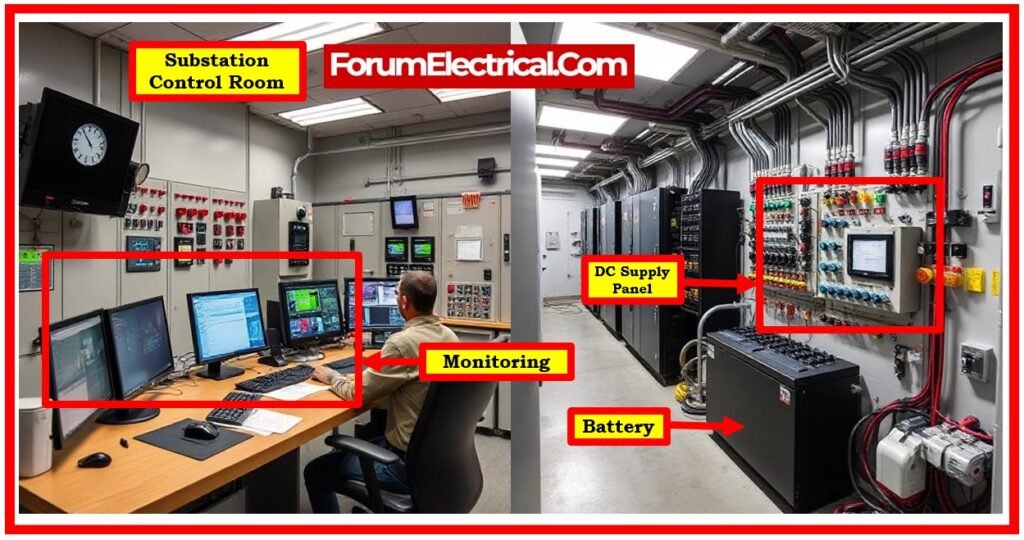

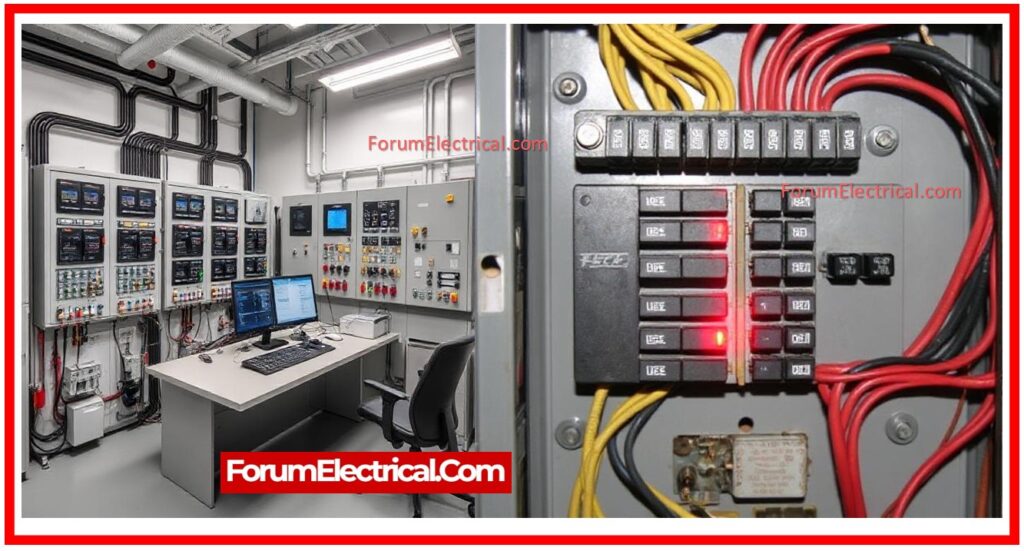

DC Power Supply System in Electrical Substation

An electrical substation’s DC supply system is essential to maintain its fundamental functioning.

In other words, DC powers all modern numerical

- Protection relays,

- Shutting tripping coils,

- Alarms,

- Hooters,

- Indications, and

- Communications devices.

Additionally, some energy meters run on DC power.

Thus, the substation’s protection, communication, control, & measurement devices are all kept operational by the DC supply system.

To ensure the safe and orderly usage of electrical power, we distribute power using switch gears and circuit breakers.

Turning on and off the electrical supply is the primary function of the breaker. Additionally, the circuit breaker performs protective duties.

The circuit breaker is tripped by the protection system in the case of an electrical malfunction, cutting off the power to the affected area.

Therefore, in an electrical network, a breaker is employed for

- Closing

- Cut off

- Breaker tripping in the case of malfunction

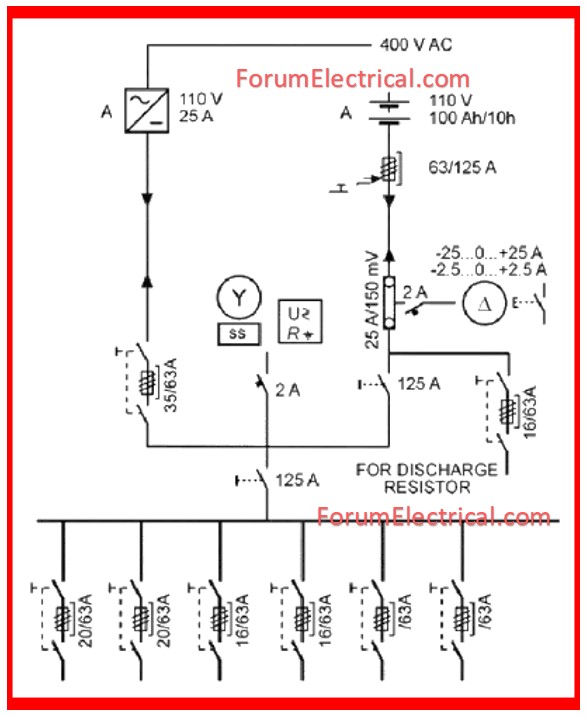

When we power the closing & tripping coil with 110 VDC, the circuit breaker turns on and off and trips.

Ex: In the case of a fault, the protective relay instructs the breaker to trip. The breaker’s tripping coil is rated for 110 volts.

Heavy current runs via the electrical network if the 110 V supply fails because the breaker cannot trigger.

In this case, without a DC source, the upstream breaker won’t trip.

If the breaker doesn’t trip, the fault won’t be fixed, and the high current in the electrical network could seriously harm equipment and switch gears. The risk of a fire in this situation cannot be eliminated.

Therefore, the 110 V DC supply system is essential for protecting a substation’s electrical network.

If it fails, the consequences can be disastrous when

- Misoperation of circuit breakers,

- Failure of protection relays, or

- Complete shutdown of the substation.

Identifying these failures is important for all substation engineers, technicians, and maintenance personnel.

Let’s look at the 7 most prevalent causes of DC distribution failures & how to prevent them.

7 Causes of DC System Failures

1). Battery Bank Failure

Causes:

- Natural aging of the batteries

- Sulfation from inappropriate charging

- Failure to perform preventive maintenance

Solutions:

- Conduct frequent capacity and discharge testing.

- Ensure enough ventilation in battery rooms.

- Replace batteries that are nearing their end of life.

Recommendation:

- Utilize battery monitoring systems & track performance patterns to identify deterioration early.

2). Charger Malfunction

Causes:

- Voltage fluctuations

- Component Damage

- Incorrect charging settings

Solution:

- Use high-quality industrial chargers.

- Enable redundant charging systems.

- Periodically verify and calibrate charger settings.

Recommendation:

- Regularly check charger output voltage and current to prevent battery damage.

3). Ground Faults in DC Circuits

Causes:

- Moisture infiltration

- Insulation was damaged.

- Loose or broken wiring.

Solution:

- Regularly test insulation resistance (IR).

- Protect the cables from environmental exposure.

- Improve grounding using earth leakage detecting systems.

Recommendation:

- Install insulation monitoring devices (IMDs) to detect issues early in ungrounded DC systems.

4). Overloaded DC Circuits

Causes:

- Causes of overloaded DC circuits include adding loads without improving the DC infrastructure.

- Insufficient load planning.

Solution:

- Perform annual load assessments.

- Extend the system with additional DC panels (or) the distribution boards.

Recommendation:

- Keep DC bus loads below 80% of the rated capacity to accommodate transient conditions and future expansion.

5). Breaker (or) Fuse Failures in DC Panels

Causes:

- Causes of breaker (or) fuse failures in the DC panels include aged or mis-coordinated fuses.

- Incorrect selection of breakers (or) fuse ratings.

Solution:

- Test fuses/breakers regularly.

- Follow the correct coordination curves.

- Use redundant pathways for crucial DC loads.

Recommendation:

- Instead of just replacing blown fuses, examine the root cause & match ratings to load characteristics.

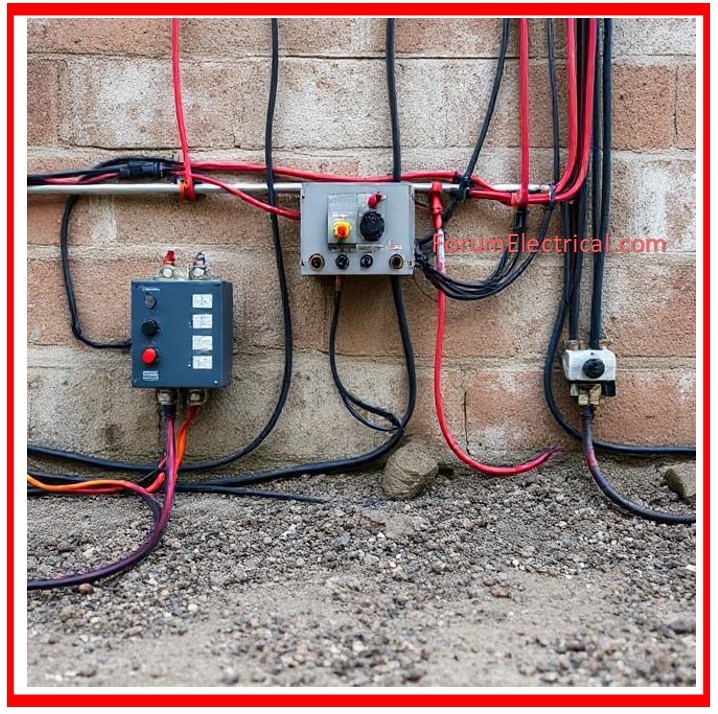

6). Loose (or) Corroded DC Connections

Causes:

- Vibrations of surrounding equipment

- Humid or corrosive conditions.

- Poor terminal torqueing during installation.

Solution:

- Retighten terminals using torque wrenches.

- Apply anti-corrosion pastes or coatings.

- Utilize vibration-resistant connectors in important places.

Recommendation:

- Thermographic scanning throughout live operation can identify hot regions and loose joints.

7). Communication Failures in DC Supervisory Systems

Causes:

- Faulty relays (or) interface modules.

- Broken wires (or) signal noise

Solution:

- Use fiber optic cabling for better noise immunity.

- Implement two communication lines to provide redundancy.

- Schedule SCADA/RTU health checks & firmware upgrades.

Recommendation:

Why is DC supply used in Substations?

The utilization of a direct current (DC) supply in substations is primarily driven by the purpose of ensuring a constant supply of power via the control circuit.

Direct current (DC) power is dependable, can be easily controlled from the battery source & makes it possible to solve faults with portable substations.

Which Protective System is needed for 110V DC supply constant monitoring?

The trip circuit supervision relay keeps a check on the condition of the DC power supply during breaker shutting and tripping because of the importance it is to substations.

If the 110V DC circuit is unhealthy, the breaker won’t go off.

When 110V DC supply system is operating normally, the trip circuit supervisory relay sends out an alert signal to help with early supply system troubleshooting.

Two trip circuits can be added to the 110V DC supply to increase its dependability. Other trip circuit will operate in case that the first one fails.

To protect an electrical network, it is therefore essential to constantly check the tripping circuit’s health.

Conclusion

A well-maintained DC system is the foundation of substation reliability. Most failures can be avoided with:

- Preventive maintenance.

- Smart component selection.

- Load & insulation monitoring.

- Communication redundancy.

If you want to ensure minimal downtime and optimum protection, DC system health must be at the top of your maintenance routine.