- Overview

- Preparation for the Repair & Maintenance of Power Distribution Lines

- Maintenance Tools for Power Distribution Lines

- What are the most efficient techniques for Maintaining Power Distribution Lines?

- Distribution Lines Inspection

- Breakdown Maintenance

- Preventive Maintenance

- Checklist for inspecting Overhead Power Distribution Lines Maintenance

- Importance of Distribution Line Maintenance

- Power Distribution Line Maintenance Challenges

- Distribution Line Maintenance Best Practices

- Different Distribution Line Faults and Repairs

- Repair Techniques in Distribution Lines

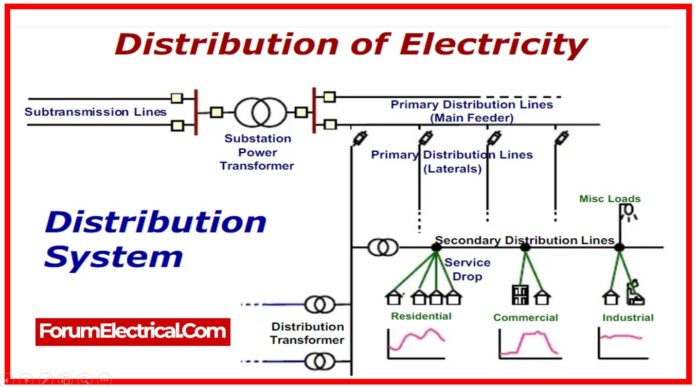

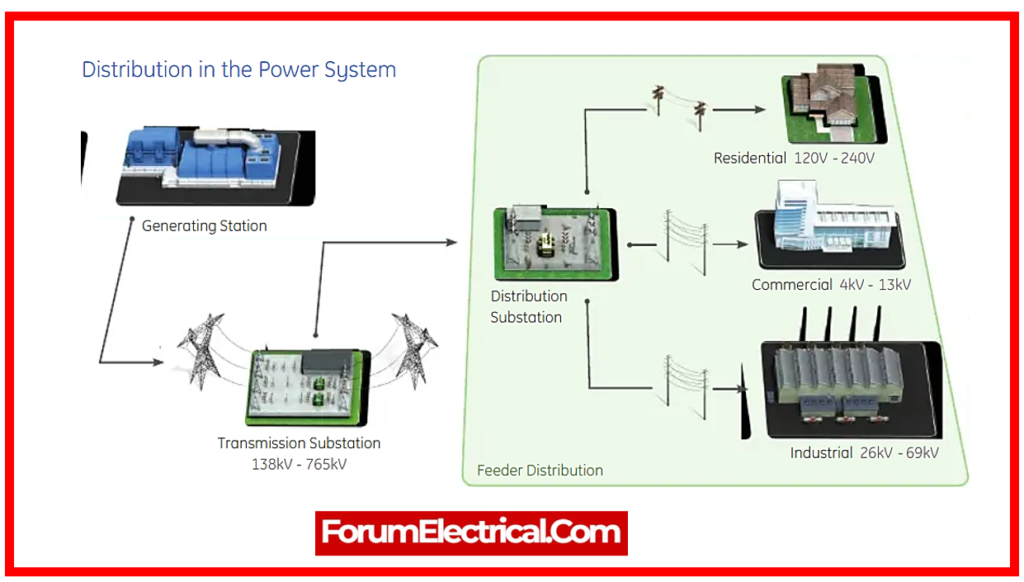

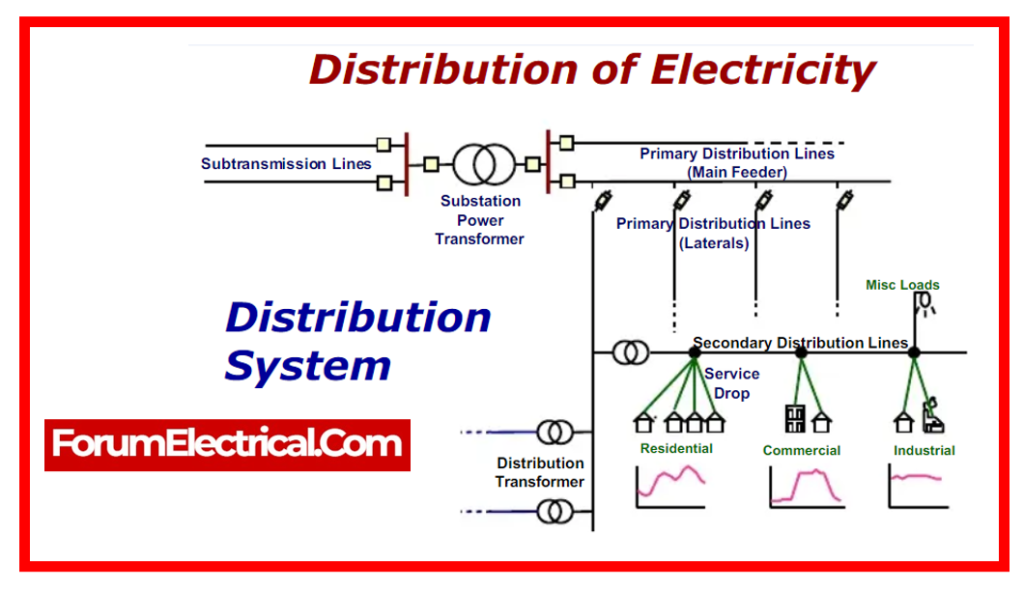

Overview

Line repair and maintenance are essential for ensuring an uninterrupted supply of power. Maintenance is primarily performed every year, once before monsoon & again after monsoon, to determine whether any breakdowns have happened in the line.

Some of the operations performed during maintenance include

- Line patrolling,

- Maintaining ground clearance,

- Replacing insulators,

- Restringing lines,

- Replacing burnt jumpers,

- Replacing broken conductors,

- Replacing damaged poles, and so on.

Proper line maintenance extends its life significantly.

Preparation for the Repair & Maintenance of Power Distribution Lines

Power Distribution Materials and Accessories are

- Poles (Supports)

- Conductors

- Insulators

- Pins for Insulators

- Guy Assembly

- G.I. Wire

- GO Switches

- 11kV Cross-arms

- L.T. Line Spacers

1). Poles (Supports)

Regardless of the material used (steel, cement, wood, etc.), the poles & supports must be securely placed and adhere to all applicable codes & standard like NESC Rule 230C and ANSI/IEEE 516-2009. When inspecting distribution line poles for routine (or) unexpected repairs, it is important to observe for:

- Conductor type & size,

- pole strength

- Wind speed

- Maximum of linear tension

- Potential dangers like trees, farms, windmills, traffic signs.

- Junctions when a distribution line crosses a body of water, a roadway, a railroad, etc.

2). Conductors

During routine & emergency distribution line maintenance, aluminum conductors are inspected.

- AAC (All Aluminum Conductors),

- ACSR (Aluminum Conductor Steel Reinforced), &

- AAAC (All Aluminum Alloy Conductors) are examples.

Based on tensile strength, all of these conductors have a predetermined minimum factor for safety.

3). Insulators

Insulators, which include

- Pin Type Insulators – Secured to the distribution pole cross arm

- Shackle Type Insulators – Used to isolate live conductors and are mounted on every electrical line, are also inspected during distribution line maintenance

- Disc Type Insulators – Employed in higher voltage circumstances and require more labor and time to operate with and maintain, are also available

- Guy Strain Insulators – Only work in mechanical tension (or) strain and are exclusively used for guy wires.

4). Pins for Insulators

All pin insulator pins are forged in a single piece, &all ferrous parts need to be galvanized.

They are available in two standard sizes:

- Large Steel Head &

- Small Steel Head.

5). Guy Assembly

Guy wires prevent dead-end wires & angular distribution lines from the collapsing due to line tension, making guy assembly an especially important element of distribution line maintenance.

6). GI Wire

GI Wires serve as reinforcement for distribution lines where they cross something, including a road, a railroad track, (or) another power line. To ensure that they do not fail, these must be inspected on a regular basis as part of the power line maintenance.

7). GO Switches

GO Switches (Gang Operated Switches) work as a gang of three switches. These, also known as air break switches, are inspected as part of appropriate distribution line maintenance.

8). 11KV Cross-Arms

For 11kV lines, there are numerous types of cross arms available, including

- V cross arms,

- Double-channel cross arms, and

- L.T. cross arms.

9). L.T. Line Spacers

Finally, the L.T. Spacer, which is available in Spiral or Composite, is an important component of effective distribution line maintenance. These are located in the middle of the lines & prevent sag caused by wind or heavy snow.

Maintenance Tools for Power Distribution Lines

| Tool | Purpose | Pictorial Representation |

| Spanner | Used to create grip when applying tension to things such as a nut (or) a bolt. A spanner with a changeable diameter for tightening various sized nuts and bolts | |

| Wrenches | Utilized to tighten nuts of varied sizes by allowing rotating motion in just one direction & prohibiting motion in the opposite direction. | |

| Screwdrivers | Used to turn, tighten, or remove screws. |

What are the most efficient techniques for Maintaining Power Distribution Lines?

1). Inspection and Monitoring

Inspection and monitoring are essential aspects of power distribution line maintenance. This includes evaluating the condition and performance of line components including conductors, insulators, towers, & fittings using a wide range of procedures and equipment. Inspection and monitoring can assist in detecting and diagnosing any defects, damages, (or) anomalies that may affect the integrity and functionality of the line.

- Visual Inspection,

- Infrared Thermography,

- Corona Detection,

- Vibration Analysis, &

- Partial Discharge Measurement

are some popular inspection and monitoring procedures.

2). Cleaning and Washing

Cleaning and washing are two other efficient methods for maintaining power distribution cables. This includes eliminating any dirt, dust, pollutants, or toxins that may have accumulated on the exterior of the line components, particularly the insulators. Cleaning and washing can help you increase electrical insulation and reduce the chance of flashovers, arcing, (or) corona discharges, which may lead to power outages, fires, or equipment damage.

- Manual Cleaning,

- Water Jetting,

- Chemical Cleaning, and

- Dry Ice Blasting

are some of the most prevalent cleanings and washing processes.

3). Repair and Replacement

Inspection & monitoring might indicate that some of line components are damaged, worn out, (or) defective without repair. In these cases, maintenance and replacement are the most effective methods of maintaining electricity distribution lines. This involves repairing (or) replacing any faulty (or) degraded parts with new (or) reconditioned ones that match the relevant standards and specifications. Repair & replacement can help to restore the line’s functionality and reliability while preventing further deterioration (or) failure.

- Splicing,

- Clamping,

- Wrapping, &

- Tensioning

are some popular ways of repair and replacement.

4). Upgrading and Retrofitting

Upgrading and retrofitting power distribution lines is another means of keeping them in good condition.

This entails improving or changing current line components or introducing new ones in order to increase the line’s performance, efficiency, or capacity. Upgrading & retrofitting can assist manage rising electricity demand, minimize transmission losses, boost voltage levels, and integrate renewable energy sources.

Some popular ways for updating and retrofitting include reconductoring, re-insulating, inserting shunt reactors (or) capacitors, (or) adding optical ground wires (or) fiber optic sensors.

5) Testing and Commissioning

The final step for maintaining lines for power distribution is testing & commissioning. This involves testing and certifying the functioning, performance, and safety of the line components following any maintenance activity, that includes inspection, cleaning, repair, or upgrading. Testing and commissioning can assist you confirm that the line satisfies the design & operational requirements, as well as the relevant codes & standards. Some popular procedures for testing & commissioning include

- Continuity testing,

- Insulation resistance testing,

- Impedance testing,

- Voltage testing, and

- Current testing.

Distribution Lines Inspection

All distribution lines and each structure should be inspected, and the following components should be checked:

- Conductor condition.

- Conductor sag & clearance to the ground, trees, & structures.

- Insulator conditions.

- Line hardware for the roughness & tightness. Excess inhibitor must be taken off conductors to avoid corona discharges.

- Structure vibration & alignment.

- Guys for anchors that are peeling out, guy wire conditions, & missing guy guards.

- Ground-wire connections & conditions.

- Ground resistance at every structure.

- Structure foundations for washouts (or) damage.

Breakdown Maintenance

When an overhead line trips due to a sustained fault, it should be checked to determine the nature of the fault, which could be slack sag, conductor snapping, tree branches touching the lines, or conductor falling on the cross arms.

An improvement should be planned and implemented as soon as possible in order to avoid the recurrence of such faults in the future. Complaints about no power/failure of power supply, voltage fluctuation, load shedding, and scheduled outages must be addressed by the senior lineman in accordance with the regulations.

Current problems, which include no current (or) a failure of the power supply in the premises, can occur for a variety of causes, including:

- Fuse blown out/tripping of MCB

- Burnt meter

- Broken service line

- Service line snapped from pole

- Fault in distribution mains

- Distribution transformer failure

- Fault in HT system

- Problem in grid (33 KV, 110 KV) substation

- Planned/scheduled/emergency maintenance work

- Load shedding

- Street light complaint

Preventive Maintenance

The following actions are included in the distribution network preventive maintenance:

- Determine the load on each phase at regular intervals & balance the load in all three phases by moving the load from severely loaded to lightly loaded.

- Examine the voltage regulation at the consumer’s location. If the voltage drop exceeds the allowable value, more distribution transformers (s) should be installed to lessen the voltage drop.

- Provide LT-less service to a narrow range of consumers whenever practicable by establishing 3 to 5 KVA,11/440 KVA transformers positioned on HT (11 KV) line supports.

- Wherever possible, replace conventional overhead whether proof household / commercial service connection wires with underground cables with the same conductor material as LT distribution line conductors.

- Determine the vertical position of line supports & accompanying structures.

- Check the tightness of the stay wires and the soundness of the stay insulators.

- Line insulators that are damaged or broken should be replaced.

- Keep line conductors & other live parts clear of the ground, structure, and building.

- Remove any bird nests, darts, or chemicals from the cross arms and insulators.

- Clean creepers that develop along the stays and supports

- Verify the earth’s resistance.

- Check the mechanical integrity of conductors, C.I. blocks, earth wires, bolts, nuts, clamps, supports, cross arms, and so on.

- Use anti-corrosive paint on any metallic parts.

- Examine the alignment & soundness of the AB switches.

- Inspect the horn gaps & lighting arresters for good operation.

- Check the distribution transformer oil for appropriate dielectric strength (BDV).

- Inspect the HT & LT fuse carriers and replace them if they turn out to be defective.

Checklist for inspecting Overhead Power Distribution Lines Maintenance

Overhead powerline maintenance is essential to reduce interruptions and increase power supply efficiency. Overhead lines must be inspected on a regular basis to identify any faults that could lead to a power outage.

Whenever an overhead line trips, the cause of its failure should be determined. Low Tension (LT) Line Maintenance includes the following:

1. Pole alignment and leaning poles should be corrected.

2. Repair of a damaged service wire

3. Bird nest removal

4. Tree clearing and cutting must be done correctly.

5. Inspected pole fittings & street light brackets

6. Thorough evaluation of L T conductor damage, such as black patches on the conductor

7. Line sagging should be minimized.

8. Lines should be correctly aligned by tightening them with the appropriate bolts and nuts.

9. The earthing system should be tested.

10. Torn or flash over insulators must be replaced.

11. Jumpers at the cut points must be evaluated.

12. Stay wires must be properly positioned.

Importance of Distribution Line Maintenance

For different reasons, effective distribution line maintenance is essential

1). Reliability

Well-maintained distribution lines reduce power interruptions and ensure that consumers have continuous access to electricity. Power reliability is important for both companies and houses to avoid productivity losses and complications.

2). Safety

Faulty distribution lines may cause electrical accidents, putting public safety at risk. Regular maintenance assists in the identification of potential hazards and the mitigation of risks, resulting in a safer environment.

3). Efficiency

Maintaining distribution lines increases power flow and lowers energy losses, improving the electrical grid’s efficiency. As a result, carbon emissions are reduced and sustainability is promoted.

Power Distribution Line Maintenance Challenges

Maintaining distribution lines is filled with difficulties:

1). Climate Conditions

Distribution lines are continually subjected to adverse weather conditions like as storms, high winds, and freezing temperatures. These conditions can lead to line damage, demanding regular inspections & repairs.

2). Vegetation Management

Overgrown trees & branches near electricity lines may lead to power outages and even fires. Effective vegetation management is necessary for ensuring continuous power supply and minimizing dangers.

3). Aging Infrastructure

Numerous distribution lines were laid decades ago and have now reached or exceeded their expected lifespan. To extend its lifespan and improve operational effectiveness, aging infrastructure needs proactive maintenance & periodic improvements.

Distribution Line Maintenance Best Practices

According to best practices is essential for addressing the problems listed above and ensuring optimal performance:

1). Regular Inspections

2). Vegetation Management

3). Asset Management

By using asset management procedures, utilities may monitor the condition & performance of the distribution line assets. This method based on information improves in the scheduling of maintenance activities, the optimization of resource allocation, and the reduction of downtime.

4). Smart Technology Integration

- Smart technology including

- Sensors,

- Real-time monitoring systems, &

- Predictive analytics

can transform distribution line maintenance.

These technologies enable in

- Detection of problems in real time,

- Prediction of failures, and

- Provision of preventative maintenance before large disruptions occur.

Different Distribution Line Faults and Repairs

Elements to inspect in order to identify and repair a malfunction in the distribution lines:

| S.No | Description of Faults | Repairs |

| 1 | Trees, bamboos, sugarcane, banana etc. near lines | Trimming of trees. |

| 2 | Building structure/over bridge/railway line/others near line. | Report to XEN for n/a. |

| 3 | Any crack around foundation of tower/pole. | Repair. |

| 4 | Tree cutting or burning of crops by local people near the line. | Report to authority for n/a |

| 5 | inclined pole/tower | Straitening |

| 6 | Damaged pole/tower | Repair/Replacement. |

| 7 | Corroded/Rusted Pole Cleaning/Painting | Cleaning/Painting |

| 8 | Missing of tower member Re-install | Re-install |

| 9 | Missing of bands/washers, nuts & bolts. | Re-install |

| 10 | Loosening of bolts | Tightening |

| 11 | Crack or damage on concrete foundation | Repair |

| 12 | Missing of tower/pole earthing | Earthing done. |

| 13 | Damaged cross-arm/fittings. | Repair/Replacement. |

| 14 | Corroded/rusted/x-arm/fittings | Cleaning and painting |

| 15 | Bent/inclined x-arm/fittings | Straightening |

| 16 | Broken/damaged/cracked insulator | Replace |

| 17 | Dirt/nest of birds on insulator | Cleaning |

| 18 | Loose nut/tension clamp/suspension clamp | Tightening |

| 19 | Loose binding of Conductor with insulator | Tightening |

| 20 | Broken strand | Sleeve fitting |

| 21 | Too much sag | Sag adjusting |

| 22 | Conductor joint not ok | Joint repairs |

| 23 | Damaged insulated conductor | Installation/repair |

| 24 | Under size conductor | Replace |

| 25 | Defective/damaged preformed armor rod | Replace |

| 26 | Obstructs on conductor such as kite, dead bird etc. | Remove |

| 27 | Damaged/corroded Earth wire | Replace |

| 28 | Loose Jumper/PG Clamp/Connector | Tightening |

| 29 | Loose Guy Wire/Stay line | Tightening |

| 30 | Missing guy wire | Install |

| 31 | Corroded guy wire/anchor rod | Replacing/Repairing |

| 32 | Damaged insulator of Isolator | Replacing |

| 33 | Unsmooth operation of Isolator | Replacing/Repairing |

| 34 | Unsmooth operation of blade of Isolator | Replacing/Repairing |

| 35 | Corroded Isolator | Cleaning/Painting |

| 36 | Loosening of nuts of Isolator | Tightening |

Repair Techniques in Distribution Lines

1). Recloser

Recloser is a device utilized in electric power distribution.

Reclosers are used to identify and interrupt transitory flaws in overhead distribution systems. Because many overhead lines short-circuit clear spontaneously, a recloser improves service continuity by immediately restoring power to the line following a transient problem.

2). Auto-reclosers

A circuit breaker with an auto recloser mechanism can shut off the breaker once it has been blown due to a problem.

Residential customers in distribution end exposed by affected overhead electrical wires may experience auto-reclosers.

If the fault affects the customer’s distribution circuit, they may experience one or more quick, complete outages accompanied by both normal operation (as the auto-recloser restores power after a transient fault) or a complete outage of service.

If the problem is on an adjacent circuit, the customer may see many brief voltage “dips” when the heavy fault current passes into and interrupts the adjacent circuit. An electrical storm may cause residential lighting to dim or go out. Auto-recloser action may cause electronic equipment to lose time settings, volatile memory data, halt, restart, or be damaged by power interruption. Such equipment owners may need to protect devices from power outages.

3). Sectionalizer

Reclosers may work with downstream protective devices known as sectionalizers, which are disconnectors or cutouts with a tripping mechanism activated by a counter or a timer.

The fault current is not interrupted by a sectionalizer. The auto-recloser monitors fault current & circuit disruption. If the auto-recloser cycles & the fault continues, the sectionalizer will open its branch circuit during the auto-recloser’s open time, isolating the problematic segment of the circuit.