What is meant by a PLC?

PLC is an acronym for Programmable Logic Controller.

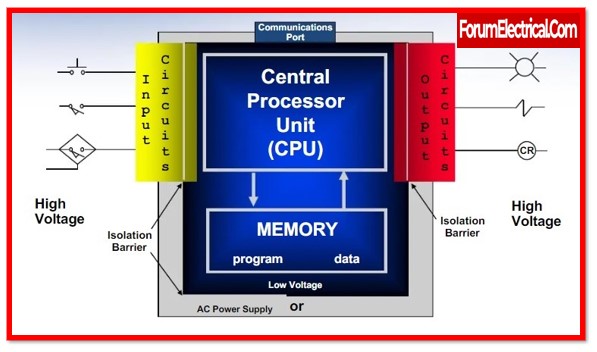

They are often used in industrial applications and lack a keyboard, mouse, and monitor since they are typically configured to operate a system or equipment.

The system (or) machine user rarely communicates directly with the PLC programme. A PC is generally linked to a PLC when it is necessary to generate or change the programme.

The PLC features a substantial amount of real-world I/O connection functionality. Most PLC variants have a large number of replaceable I/O modules, allowing for compatible connection with nearly any type of laboratory (or) industrial equipment.

What is PLC Ladder Logic?

PLCs are often programmed using Ladder Logic. Ladder Logic is primarily a Boolean logic-solving programme with a graphical user interface designed to resemble a simple wiring schematic, which is used by all electricians.

What is meant by HMI?

An HMI is also referred to as an MMI.

HMI is an abbreviation for Human to Machine Interface, whereas

MMI is an abbreviation for Man to Machine Interface.

Even if MMI is not politically acceptable, the term is getting less and less used.

HMI’s function is to interpret human signals and intents into electric signals that may be used by the machine’s information system.

As a result, the human operator is able to make interactive adjustments to the data & software processes.

HMIs typically include a display to help the operator to differentiate between relevant data and the action being performed.

The development of computers has had & continues to have a significant influence on business and society. With the present development of computers, software & hardware are always being enhanced.

Computers are becoming more powerful, and they will eventually provide a human-machine interaction.

While the other tool is PLC-based and hence supports interfacing. One kind of equipment is claimed to be based on Human Machine Interface technology and does not comply with network interface (or) computer. It contains a USB connector that may be used to download data.

Difference Between PLC and HMI

Industrial automation systems employ PLC and HMI for different objectives.

| SERIAL NO | PLC | HMI |

|---|---|---|

| 1 | PLCs can handle industrial field inputs & outputs & execute advanced control algorithms like PID and motion control. Ladder logic and function block diagrams, and structured text programming PLCs. | Operators manage industrial operations using HMIs. HMIs monitor and control industrial processes using PLCs and are user-friendly. HMI interfaces employ visuals, touch displays, and keypads. |

| 2 | There is no display of units. | In the HMI, there will be a unit display with function buttons. |

| 3 | The user cannot see what is occurring in the PLC execution. | It can keep control of what is going on during executions. |

| 4 | The PLC is only in auto mode. If an error occurs during the procedure, the user cannot progress until it is rectified or remedied. | HMI may function in both manual & automatic modes. |

| 5 | The set point in the PLC cannot be changed. If changes are required, the programme licence must be downloaded. | HMI has the ability to alter the set point. |

| 6 | PLCs are used in industrial settings to control specialised operations, such as machines on a manufacturing floor. | HMIs are utilised to establish a link between a human operator & the PLC-controlled process. |

| 7 | The PLC accepts sensor input, processes it using a programme, and then sends output to the actuators for controlling the process. | HMIs show process data and enable the operator to enter instructions, yet they do not manage the process directly. |

| 8 | The process is directly controlled by the PLC using normal industrial communication protocols. | HMIs are linked to PLCs and used to show process data, but they do not interact directly with the process under control. |

| 9 | PLCs are often more complicated than HMIs since they are in charge of regulating the process & making alternatives based on sensor data and operator inputs. | HMIs are less complicated since they merely show data and enable the operator to enter instructions. |

| 10 | PLCs are used in industrial automation and control. | HMI pertains to human-machine communication |

| 11 | For programming, PLCs employ ladder logic and function block diagrams, (or) structured text. | For user interface, HMI employs graphics, touch displays, and keypads. |

| 12 | PLCs are capable of handling high-speed inputs and outputs. | HMI is used to monitor and control process variables. |

| 13 | Complex control algorithms may be programmed into PLCs. | The HMI shows real-time process data as well as warnings and notifications. |

| 14 | Industrial protocols such as Modbus and Profibus, and Ethernet/IP are used by PLCs to communicate. | Through industrial protocols like OPC, HMI connects with PLCs and other devices. Allen-Bradley, Siemens, and Mitsubishi Electric are a few examples. |

| 15 | PLCs are utilised in a variety of sectors, such as manufacturing, process control, & building automation. | HMI and PLC work together to create a user-friendly interface for the monitoring & managing industrial operations. |

| 16 | PLCs are configured to carry out complicated control algorithms like PID control & motion control. | HMI is used to show real-time process data in order to make process modifications. |

| 17 | PLCs may be set up for remote access & monitoring. | HMI allows for historical data recording and reporting. |

| 18 | PLCs are linked to other industrial equipment such as sensors & actuators. | HMI supports several languages, enabling operators from various nations to easily use it. |

| 19 | PLCs are employed in safety applications including emergency stop and interlocking. | The HMI is used to obtain data from safety logic. |

| 20 | PLCs are employed in tough industrial settings with extensive temperature fluctuations, dust, and vibration. | HMI is often intended for indoor usage in a controlled environment, while PLC may be utilised in standalone or networked systems. For monitoring reasons, HMI may be linked with PLC and SCADA systems. |

| 21 | To prevent unauthorised access, the PLC programme may be password secured. | HMI may be set to enable user access levels as well as security controls to prevent unauthorised access or process modifications. |

| 22 | The PLC may be set up to control the process either automatically or manually. | HMI can control recipes, enabling operators to quickly switch between multiple process parameters. |

| 23 | PLCs may be utilised to connect to IT systems including ERP, MES, & cloud-based platforms. | HMI may be set up to provide real-time alerts through email, SMS, (or) other messaging systems. |

| 24 | Libraries, network configuration, hardware configuration, & other sophisticated tools may all be defined and used in PLC. | HMI allows you to create and manage audit trails, reports, patterns, printouts, and other sophisticated features. |

| 25 | The PLC controls the system. | The HMI acts as the visual interface. |

Conclusion

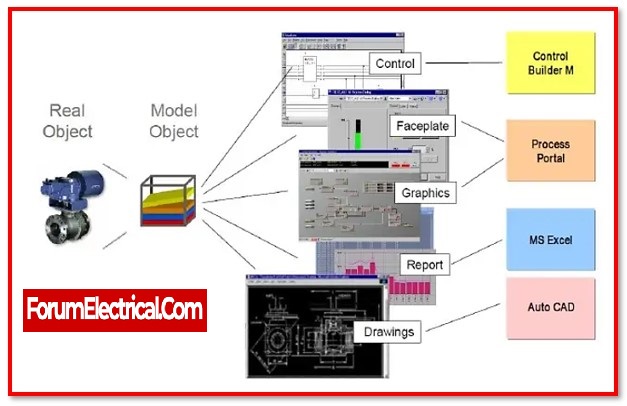

PLCs are insertion type ladder logic controllers with programmable parameter set-points for an automation control function. HMI often has a PC-based interface with regularly customizable software and more extensive capabilities.

An HMI is a device that displays the IOs, settings, and other operations in the PLC logic and thereby displays the completed system. So, HMI is essentially a graphics system. To operate with it correctly, one must be familiar with the symbols, colour schemes, icons, and graphical layout.

Industrial operations are controlled and automated using programmable logic controllers. A graphical user interface known as Human-Machine Interface connects PLCs and human operators.