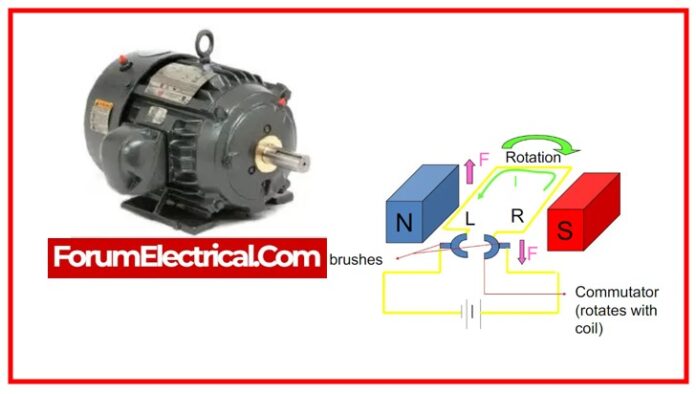

Electric Motor

A device that makes use of the concept of energy conversion which transforms electrical energy into mechanical energy is an electric motor. The

- Rotor,

- Stator,

- Windings,

- Air gap, and

- Commutator

are the primary components that make the process go further. An electric motor’s efficiency ranges between 70% and 85% (additional energy is used by the sound & heat it emits).

Electric motors are vital to daily life, whether they are used for labour-intensive projects .

Electric Motor Applications

Large and small electric motors may be employed in a variety of home and industrial applications.

They may be used as water pumps at home for a variety of purposes such as central heating, fish tanks, and so on. In addition, many of the electrical appliances found around the home, such as

- Food processors,

- DVD drives,

- Garage door openers,

- Power windows, and so on,

all make use of electric motors.

Electric motors are used in a variety of applications such as mills, lathes, forklift trucks, extruders, and so on. These machines are responsible for a substantial portion of work.

What are the steps involved in installing an electric motor?

In order to successfully install an electric motor, one must adhere to both the

- General Requirements and

- Specific (or) Specialised requirements

that are outlined below.

1). General Conditions or Requirements

- The type of motor that must be placed is influenced by the surroundings.

- Any Variable Frequency Drive (VFD)-controlled motors must be IEC or NEMA inverter duty rated.

- Article 430 of the NEC must be followed.

- If the motor’s nameplate is concealed (or) unclear (or) uncertain after installation, another one must be installed somewhere visible.

- If the motor is positioned at a height, special care must be made to the insulating restrictions.

- If the surface temperature surpasses 60°C, the motor must be guarded.

- Clear signs & arrows should be raised up so that reverse-rotation events do not occur, posing a health risk or causing equipment damage.

- RTDs & a temperature relay system are required for motors above 55 kW to shut down if extremely high temperatures are attained.

- Certain performance requirements must be met when using an S1 duty rating.

- In the motor, there should be a stranded copper wire that is ground insulated, and the control panel should have one end that contains the motor starter.

- A Power and Generation (P&G) qualified electric engineer must be contacted if any unusual use demands or motors need a different duty charge than those specified above.

- Except in specific cases, connecting the motor through wire-nuts is forbidden.

- Metal boxes containing the motor junction are expected to be used.

- Continuous motor lines with a ground wire going along are to be anticipated.

- If a motor is to run continuously (or) in a condition where the temperature reaches 40°C, it needs to have a service factor (or) maintenance factor of at least 1.15.

2). Specific(or) Specialised Requirements

There are 3 specific requirements to be analysed.

Global Tools

All AC motors must be designed for 50/60 Hz & 400 VAC, and they must have a Variable Frequency Drive.

U.S Based Tools

Such motors must be designed to operate at 60 Hz & 460 VAC. Furthermore, those which are not controlled by a VFD and have a power rating of 0.75 HP or greater need thermal overload protection. Overload protection is recommended for those with less than 0.75 HP.

E.U Based Tools

The motor specifications must be compatible with 50 Hz & 400 VAC. The remaining criteria are the same as those for US-Only Tools.