- Scope

- Setting Up a Test Lab

- Testing Lab Components

- Type Test

- Routine Test

- Software Testing

- Calibration Test

- Measurement Test

- Energy Measurement Test

- On-site Testing

- CT-Operated Meters Testing

- Ratio Test with Primary Injection Kit

- Burden Test

- Phase Angle Test

- Insulation Test

- Polarity Test

- Energy Meter Users Checklist

- In Summary

Distribution utilities depend on energy meters for revenue. Utility companies send consumers bills based on meter readings. Consumers and utilities might be affected by inaccurate recording. Thus, meters must function well and be reliable.

Meters are checked & calibrated to ensure appropriate operation and accuracy within IE Rules.

Scope

This document outlines a test procedure for an energy meter.

Setting Up a Test Lab

Setting up the proper testing lab for energy meters is essential. It facilitates accurate testing and calibration of these devices.

You can configure the bench for either single-phase (or) three-phase meters. It can operate automatically, semi-automatically, (or) manually.

Testing Lab Components

The main components of an energy meter laboratory are:

- Energy meter is under test.

- Standard reference meters for voltage, current, & power.

- Power supply (o) source for the required voltage and current.

- Load bank (or) resistive load to simulate real power use.

- Voltage & current transformers for CT-operated meters, as needed.

- Automated control and data systems for completely automated labs.

Type Test

Type testing determine the way the energy meter functions and whether it follows the guidelines.

They look at its accuracy, how it functions, and whether it meets the necessary criteria.

These tests are performed early in the manufacturing process to ensure that the meter is satisfactory.

Routine Test

Routine testing are performed on a regular basis to ensure that the energy meter remains accurate.

This is necessary to ensure that it continues to function properly.

Test Type: Energy Meter Test

Test Detail: Initial tests to ensure that the meter functions properly and adheres to the guidelines.

Test Type: Energy Meter Routine Test

Test Detail: Ongoing testing to ensure that the meters’ accuracy satisfies specified levels.

Software Testing

- Any transition on the relay software that is saved on the relay is impossible, and you also cannot send it to another relay.

- In order to change any change of the setting of relay, you have to generate new program & also this new program you can sent to any relay.

- To open the file you make, click on file then select open. But be careful that we work at Reactive Power.

- Reading from the relay works by selecting the ‘Diagnostic Read’ & ‘Short Diagnostic’ option.

- Note: there is one default program saved in the PC software named Sample A3R; you can work with it (BETTER TO WORK WITH IT).

- From this program, we are having settings change based on the station and other fixed settings.

a). Variable setting: this setting is used in determining the CT & VT ratio.

b). Constant setting

Metering Quantities: included KWH‐Del, KVARH‐Del, KWH‐Rec and KVARH‐ Rec.

Display Values in normal mode:

- Date

- Time

- Voltage across of each phase.

- They are made in the current referring to each phase.

- System KW.

- System KVAR.

- System P. F.

- System FREQUENCY.

- Current Billing Total KWH –Del and KWH –Rec, KVARH‐Del and KVARH‐Rec.

- Previous Billing Total KWH‐Del, KWH‐Rec, KVARH‐Del& KVARH‐Rec (OPTIONAL).

- Register Multiplier = 1000.

There are options to choose from regarding the relay configuration for output pulse contact.

NOTE (IMPORTANT):

You have 6 contacts (A, B, C, D, E & F), but we use only 4 contacts as following:

- External relay terminal block for connecting to: (32‐30).

- External Relay Terminal block to (32‐27) [B]

- Some of the frequently used control words are described below: (C) & (D) NOT USED (DISABLE).

- Connection will be established to the external relay terminal block to (32‐29).

- RRR(F) Relay terminal bloc<|reserved_special_token_251|> external to (21‐22).

To send your program to relay you must choose PROGRAM then GO.

You can make clear the data using software by choose CLEAR VALUES & STATUES.

Calibration Test

Min Operating Current

This is the amount of current minimum the relay is able to make pulse with it to be able to allow current to pass through it.

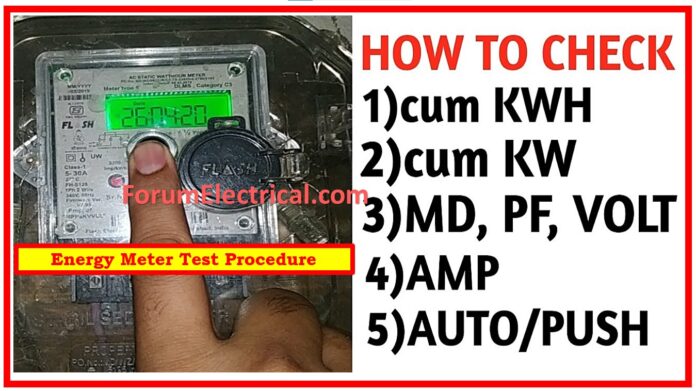

Measurement Test

This test made according to the secondary side and the relay display values also according to the secondary side.

Energy Measurement Test

In this test must calibration for Volt, Current and P. F Angle that READ out as error and this error may be effect to the energy measurement error of the relay, this calibration is done.

NOTE: 4 decimal after the point may affect the percentage error of the relay and thus you have to adjust the amount till you get the least error.

On-site Testing

There are two main methods for testing energy meters within their actual location.

- Actual Loading Method

- Phantom (or) Fictitious Loading Method

This includes the application of actual and simulated loads.

These approaches determine the way an energy meter works without requiring a specific test location.

1). Actual Loading Method

The actual loading approach entails employing the energy meter in real-world applications.

This allows us to determine whether the meter is working properly under regular situations.

It allows us to connect the meter to a standard electrical setup and measure the power consumption.

We subsequently compare this utilization to a standard to identify any incorrect measurements.

2). Phantom (or) Fictitious Loading Method

The phantom or fake loading approach simulates genuine electrical demands using a specialized test kit.

It is useful when real loads are insufficient or not available.

This kit provides a predetermined electrical load, enabling us to monitor the meter’s energy use.

We may then compare how the meter shows to this known load to determine whether it is correct.

This method is more user-friendly and versatile, particularly when real loads are too small or difficult to access.

CT-Operated Meters Testing

Energy meters interconnected to current transformers (CT) require additional tests to ensure system correctness.

Here’s the thing that we should do with CT-operated meters.

Ratio Test with Primary Injection Kit

- The ratio test is used to determine the accuracy of a CT-operated energy meter.

- A primary injection kit delivers a known current to the CT’s primary side.

- The system then examines whether the measured secondary current fits the expected value.

- This ensures that the CT ratio is within the limitations specified by the energy meter manufacturer (or) the industry standard.

Burden Test

- Measures the energy meter’s strain on the CT and ensures it is within the CT’s rated capacity.

Phase Angle Test

- Checks the phase angle displacement of the CT’s primary & secondary currents to ensure accurate power readings.

Insulation Test

- Checks the insulation between the primary & secondary windings, as well as between the windings and the ground, for safety.

Polarity Test

- Confirms the exact polarity of CT connections to energy meter, allowing for accurate power readings.

Energy Meter Users Checklist

When checking energy meters in your area, it’s important to consider the following factors:

- Verify that the meter’s seals are intact. If they are, it’s possible that someone attempted to alter something without authorization.

- Verify that the current readings on the meter correspond with the previous records. Significant variations could indicate that the meter is malfunctioning.

- Examine the meter carefully for any wear or cracks. These factors could reduce its accuracy.

- Verify that the wires are in good condition and have not been touched. The meter may not function correctly due to bad wiring.

- Additionally, look for indicators such as cracked seals or odd movements. These might indicate an attempt to tamper and manipulate the system.

- Finally, ensure that the meter is easily accessible for inspections. Difficult-to-reach areas may take longer to detect issues.

Users may ensure that their meters are accurate and reliable by carefully considering these factors. This indicates that energy prices are reasonable and transparent.

In Summary

It’s essential for companies and consumers across that energy meters function properly.

The key procedures for testing these meters have been covered in this post. It covers over the importance of energy meters, how to test them, & how to use CT-operated meters.

Everyone gets advantages from testing energy meters. It lowers waste and maintains integrity in the power system. India’s energy system is maintained efficiently and sustainably via routine inspections.