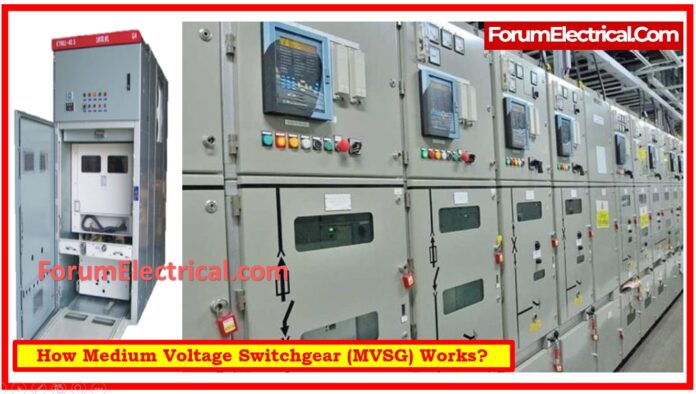

What is a Medium Voltage Switchgear?

For the purpose of switching, protection, and control in alternating current systems ranging from 1 kV to 52 kV, MV Switchgears are developed, manufactured, and tested in accordance with the IEC 62271-200 standard.

In addition, switchgears that operate at medium voltage allow for the control and utilization of said energy.

In the case that there is a sudden increase in the current or a short circuit, the MV switchgears are the ones that are responsible for reducing the current of the system.

Medium voltage switchgear is an essential component of electrical power networks, controlling and protecting electrical equipment & circuits in the voltage range of 1kV to 36kV.

There are numerous types of switchgear, each of which is comprised of medium voltage equipment. These switchgear types include

- Circuit Breakers,

- Disconnector switches,

- Current and Voltage transformers, and

- Transformer supply transformers.

These switchgear types are utilized to meet the requirements of facilities (or) distribution firms’ measurement needs.

Medium Voltage Switchgears are utilized in all industries that demand medium voltage electricity, including

- Power generation,

- Distribution centers,

- Industrial facilities,

- Renewable energy plants,

- Buildings, and

- Railways, among others.

According to the IEC 62271-200 standard, switchgears that operate at medium voltage are differentiated as follows:

- Material that is insulated: gas, air, or liquid type

- Material that serves as a partition among the compartments: PM and PI

- IAC classification for an internal arc fault is as follows: AFL / AFLR

- Complications with the continuity of service: LSC-1, LSC 2-A, and LSC 2-B

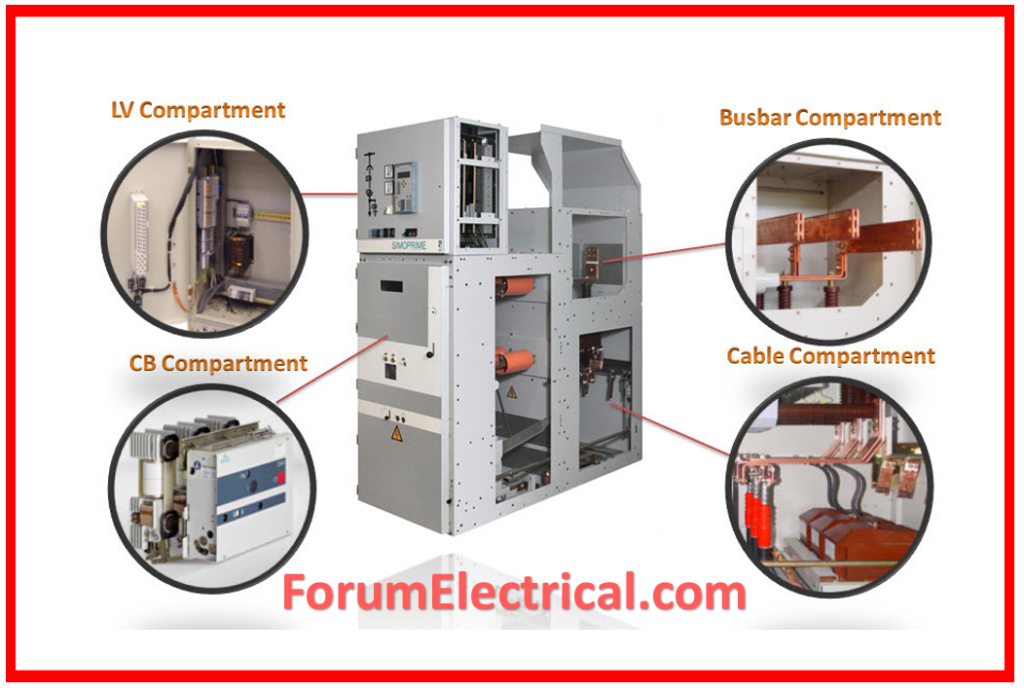

Components of Medium Voltage Switchgear

The components of medium voltage switchgear are:

- Circuit Breakers

- Disconnectors

- Fuses

- Relays

Circuit Breakers

Circuit breakers are devices that stop the passage of electric current in a circuit. They are intended to safeguard electrical equipment against damage caused by

- Over currents,

- Short circuits, and

- Other electrical defects.

Disconnectors

These are utilized to isolate elements of the electrical system during maintenance or repair.

They are frequently utilized in conjunction with circuit breakers & other safety devices.

Fuses

Fuses are devices which protect electrical equipment by blocking the passage of current when it reaches a specific threshold.

They are intended to prevent against overloads and short circuits.

Relays

Relays are devices that monitor the electrical system & trigger protective devices as needed.

They detect errors and ensure the system runs safely and reliably.

Medium Voltage Switchgear Function

Medium voltage switchgear is electrical equipment designed to switch, control, protect, and isolate electrical circuits with voltages ranging from 1 kV to 36 kV.

It is essential for distributing electrical power in industrial facilities, commercial buildings, and utility substations.

Here is a summary of how medium voltage switchgear operates:

Switching Operations

Medium voltage switchgear enables operators to manually or automatically turn electrical circuits on and off.

This is necessary for managing the flow of electricity via the various components of the power distribution system.

Protection Functions

Switchgear includes a variety of protective devices that include circuit breakers, fuses, relays, & protective relays to protect electrical equipment and personnel from failures and abnormal operating conditions.

These protective devices detect defects such as short circuits, overloads, & ground faults and isolate the problematic component of the system to avoid further damage and maintain safety.

Isolation and Disconnection

Switchgear allows you to isolate electrical circuits & equipment for maintenance, repair, (or) inspection purposes.

Isolation switches, also known as disconnectors, physically isolate the circuit from the power supply, allowing staff to work safely on the equipment.

Control Functions

Remote Monitoring and Control

Advanced medium voltage switchgear may include remote monitoring & control capabilities, allowing operators to monitor the status of electrical equipment & perform control actions via a centralized control room or a computerized supervisory control and data acquisition (SCADA) system.

Interlocking Systems

Interlocking systems are commonly used in switchgear to prevent harmful operating scenarios, such as closing a circuit breaker while the accompanying disconnect switch is open (or) vice versa.

Interlocks aid in the appropriate sequencing of processes and avoid unintentional equipment damage (or) personnel injury.

Arc Flash Mitigation

Switchgear may have elements that reduce the dangers of arc flashes, such as arc-resistant designs, arc detecting systems, and arc-flash-relief vents.

These safeguards aim to protect workers & equipment from the thermal & mechanical effects of an arc flash incident.

Types of Medium-Voltage Switchgear

There are various varieties of medium voltage switchgear accessible, each with its own set of advantages & disadvantages. These types include:

- Air-Insulated Switchgear (AIS)

- Gas-Insulated Switchgear (GIS)

- Hybrid Switchgear

- Compact Switchgear

- Metal-Clad Switchgear

- Metal-Enclosed Switchgear

- Pad-Mounted Switchgear

- Vault (or) Subsurface Switchgear

Air-Insulated Switchgear (AIS)

Air-insulated switchgear (AIS) is the most prevalent type of medium voltage switchgear, & it employs air to provide insulation between the live sections.

Although AIS is reasonably simple and reliable, its size necessitates a huge installation space.

Gas-Insulated Switchgear (GIS)

In this switchgear, the live portions are insulated with sulfur hexafluoride (SF6) gas, a highly effective insulator.

GIS uses less space than AIS, however it is more expensive & requires additional maintenance.

Hybrid Switchgear

Hybrid switchgear combines the positive characteristics of both AIS and GIS.

It utilizes a combination of air & SF6 gas for insulation, making it smaller than AIS but more dependable than GIS.

Compact Switchgear

Compact switchgear is a MV metal-enclosed switchgear device that includes sealed circuit breakers and disconnects.

It is ideal for installations in small locations or regions with limited accessibility.

The circuit breakers can be configured with three phases in a single tank (or) in an isolated phase configuration.

Compact switchgear is designed, manufactured, and tested to meet IEEE C37.20.9 and the IEC 62271.

Metal-Clad Switchgear

IEEE C37.20.2 defines metal-clad switchgear as medium-voltage electrical switchgear in which all electrical components, including the

- Incoming bus,

- Outgoing bus,

- Instrumentation, &

- Main circuit breaker (or) switch,

are protected in separate metal compartments for added safety, ruggedness, and ease of maintenance.

The rated voltage levels for range from 5kV to 38 kV.

Industrial and power generation and transmission facilities use metal-clad switchgear with draw-out circuit breakers for simpler maintenance.

Metal-Enclosed Switchgear

The IEEE C37.20.3 standard defines metal-enclosed switchgear.

Metal-enclosed switchgear houses circuit protection devices such as

- Circuit breakers,

- Power fuses, and

- Fusible switches, and also

- Control & metering equipment.

These devices are capable of being mounted in common compartments & do not require separate barriers or compartmentalization like metal-clad switchgear.

Metal-enclosed switchgear is used in commercial and industrial establishments where the incoming electrical supply exceeds 480/600 volts.

Pad-Mounted Switchgear

Pad-mounted switchgear can be described in IEEE C37.74.

Pad-mounted switchgear is intended for subsurface distribution systems with ratings ranging from 5 to 38 kV that must be functional above ground.

Pad-mounted switchgear’s outdoor rating, low profile, and tamper-resistant design make it ideal for

- Utility distribution,

- Feeder sectionalization, and

- Circuit protection.

Switches, fuses, & vacuum interrupters are utilized to protect loads, isolate faults, and reduce downtimes.

Pad-mounted switchgear is offered with up to six ways in a single insulated sealed tank. Insulation methods include air, fluid, SF6 gas, solid-dielectric-in-air technologies, and solid materials.

Vault (or) Subsurface Switchgear

The IEEE C37.74 standard defines vault or subterranean switchgear.

Vault or subsurface switchgear is intended for the electrical distribution systems ranging from 15 to 38 kV, and the switch and its accessories must be operational from within a vault or below-grade location.

These places may be dry or prone to water incursion.

Vault (or) subsurface switchgear may also be operated manually from above ground or with relays, and vacuum interrupters are used to protect loads and isolate problems.

Insulation techniques include SF6 gas, solid-dielectric-in-air technology, and solid materials.

Medium-Voltage Switchgear Installation

Medium voltage switchgear installation should be performed by a qualified professional.

This is typically a group of skilled electricians. Because of the greater voltages involved, several manufacturers also provide medium voltage switchgear training.

The training serves to ensure that their devices are properly fitted.

The first stage in installing MV switchgear is determining the power supply’s voltage and amperage.

This information is needed to determine the proper switchgear ratings for the application.

Once the MV switchgear has been chosen, the electricians must follow these regulations during the installation procedure.

- That the installation location is flat and well ventilated.

- The designs and technical information are correct, and all necessary supplies for MV switchgear installation are accessible.

- Every electrical connections are completed by qualified workers.

- Once the MV switchgear installation procedure is finished, the equipment must be tested.

This is accomplished utilizing a wide range of techniques and technologies.

These tests’ findings should fall within the manufacturer’s specified data range based on the medium voltage switchgear standards.

Medium Voltage Switchgear Maintenance

MV switchgear needs periodic maintenance.

This usually includes inspecting the components for signs of wear (or) damage.

The frequency of these inspections will vary according to the kind of MV switchgear & the application.

In general, MV switchgear preventive maintenance includes the following:

- Inspect components for the corrosion (or) filth.

- Checking the switchgear’s interlock operations.

- Checking for overheating indicators.

- Test the various components.

- Testing switchgear insulation for resistance.

In some condition, switchgear might require to be replaced because of aging or damage.

MV switchgear manufacturers typically give the relevant instructions for the devices.

However, any electrician who supervises an MV installation will normally retain a maintenance checklist.