- What is a Three-Phase Motor?

- Asynchronous 3 Phase Motor

- Advantages over Single-Phase Motors

- Typical Applications of Three-Phase Motor

- Star-Delta Motor Connection

- What is a Star Connection?

- Step-by-Step Procedure for Star Connection

- What is a Delta Connection?

- Step-by-Step Procedure for Delta Connection

- What are the differences between Star & Delta connections?

- When should utilize Star and Delta?

- What happens if a delta-connected motor is connected to a star connection?

- Which of the three-phase connections, star or delta, has the greater power handling capacity?

- Why is there no neutral wire in a delta connection?

- What is the formula for a three-phase motor’s star connection?

- How to choose between a Star and a Delta Motor Connection?

- Why are Star and Delta Connections used in three-phase circuits?

- What makes Star Connection preferable than Delta?

- Application of the Star and Delta Connection

- Codes and Standards

- Summary

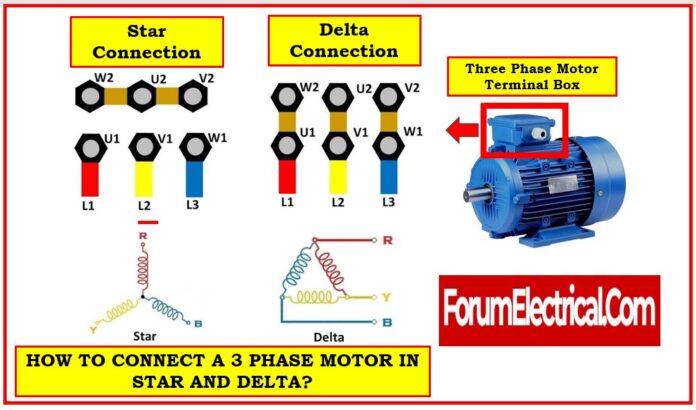

Depending on the supply voltage, the 3-phase induction motor can be connected in star or delta connections. There are six separate windings in a three-phase motor, two for each phase. During motor manufacture, the internal construction and connections of the coil within the motor are specified.

There are two types of three-phase motor connection arrangements:

- Star &

- Delta

It should be noted that the low voltage connection must draw twice as much current from the source as the high voltage connection. On their nameplates, most motors show two voltage and current values.

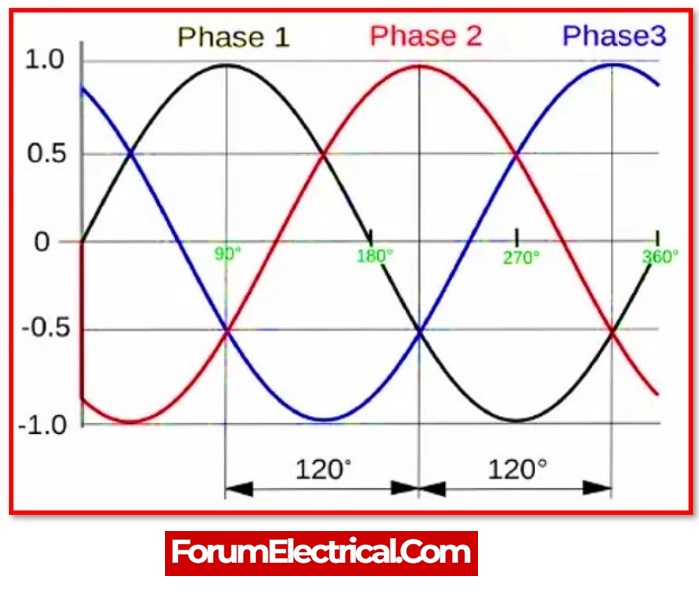

Three independent windings are used in three-phase motors. All three windings are held in the stator slots by the motor’s stator. These windings are electrically separated by 120 degrees. A three-phase alternating current (ac) system powers motor.

A star connection has four wires whereas a delta connection has three wires.

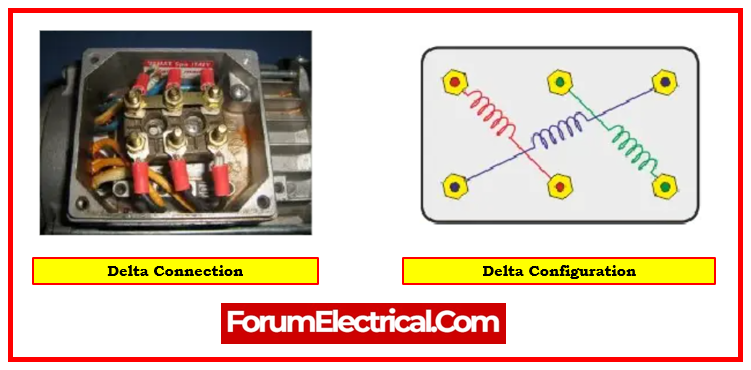

A method of starting mechanism for a three-phase alternating current induction motor is the star-delta connection. A starter is typically used to start a motor smoothly. The motor is started by reducing the starting current with a star-delta starter.

What is a Three-Phase Motor?

An electric motor that runs on three separate phases of electrical power is known as a three-phase motor. This kind of motor runs on alternating current (AC) and needs a three-phase electrical supply in order to function.

Any three-phase winding circuit can be connected in a star or delta configuration. The star connection connects all of the coil’s ends to a coon point and is powered by the other free ends.

In delta connection, connects each end of the coil to the start of the following phase, allowing the system to be transferred through the connection points.

The current flowing through each phase coincides with the line current in the star connection, while the voltage supplied to each phase is (1/√3) less than the line voltage.

In the delta connection, however, the intensity that goes through each phase is (√3) less than the line intensity. Whereas the voltage applied to each phase coincides with the line voltage.

This section will go over both the configuration of Star and Delta as well as how to connect a 3-phase motor in Star and Delta.

Asynchronous 3 Phase Motor

There are two types of asynchronous 3-phase motors.

- Those with wound rotors fall within the first category.

- The second class is one with a shorted rotor, commonly known as a squirrel cage rotor. This is because of its cage-like shape.

Advantages over Single-Phase Motors

Efficiency and Power: More power output when compared to motors operating in single phase and less vibration and smoother operation as a result of the steady power supply.

Stability and Balance: Stability is improved by distributing power evenly among the three phases and reduced electrical system stress as a result of evenly distributed loads.

Acceptability of High Loads: Excellent for heavy-duty industrial applications because of its reliable power source and ability to manage large torque loads with greater proficiency.

Typical Applications of Three-Phase Motor

- Pumps, conveyor belts, compressors, & powerful machinery are all powered by electricity.

- Essential for factory and industrial plant production lines.

- In HVAC systems, elevators, & large-scale air conditioning units are applied.

- Used in commercial structures because of its dependability and efficiency.

- Grain handling equipment, irrigation systems & agricultural machinery are all powered by three phase electric power.

- Because of their strength and power, they are essential for a variety of farming operations.

- For propulsion systems in trains, ships, & some types of vehicles.

- Power delivery for the transportation machines is efficient.

- Certain wind turbines & hydropower generators are used to generate electricity.

- Because of their dependability and power output, they are used in renewable energy systems.

Star-Delta Motor Connection

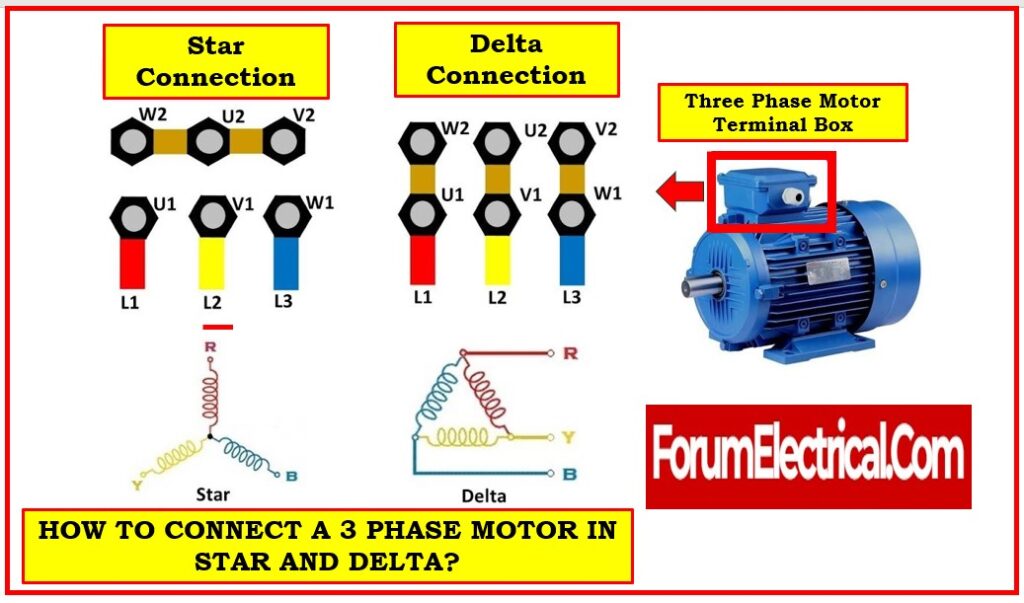

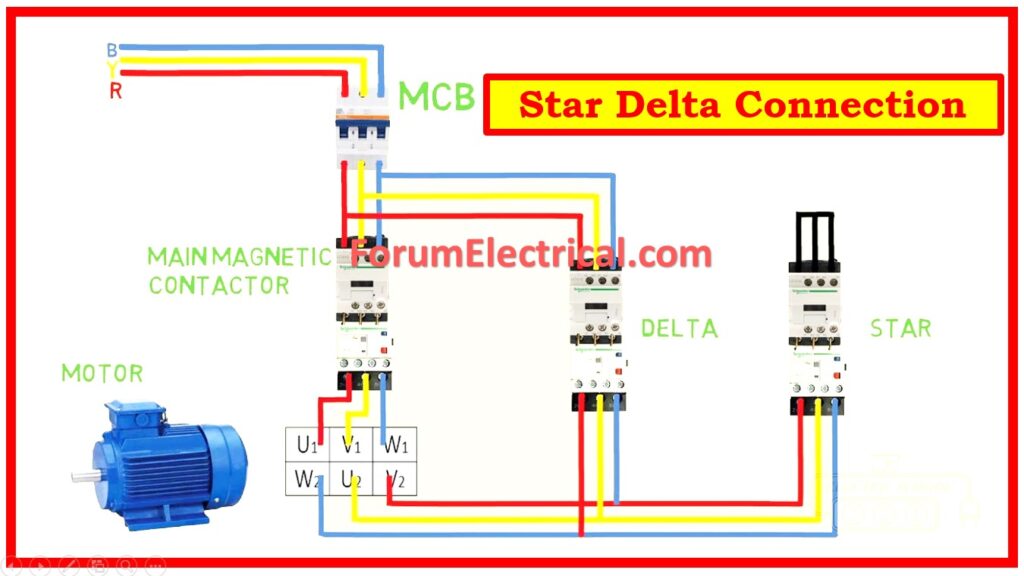

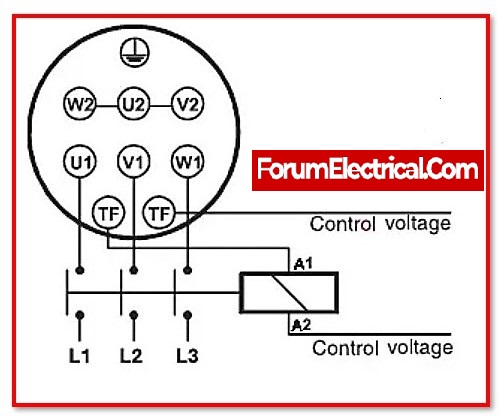

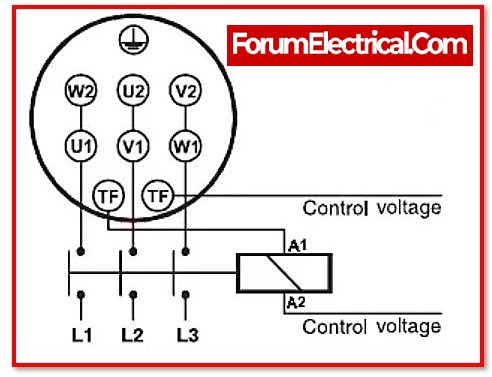

An electric motor’s stator has three windings, each with two ends. U1 and U2 are the endpoints of the first winding. V1 and V2 are the second windings. W1 and W2 are the endpoints of the third winding.

What is a Star Connection?

A star connection, also referred to as a Y connection, is made by joining the three terminals of the three-phase motor in a triangle pattern that resembles the letter “Y.”

The core of the “Y” is formed by connecting each of the 3 motor terminals (U, V, and W) to a single point in a star connection.

Step-by-Step Procedure for Star Connection

Motor Terminal Identification (U, V, W)

To form a star connection, join the windings’ ends W2, U2, and V2 as seen in the below diagram, which corresponds to the terminals of an electric motor.

Terminal Connections for Star Arrangement

The lines L1, L2, and L3 of the three-phase power supply will be connected to each end of the windings U1, V1, and W1, as shown.

The following points should be noted in a balanced Star-connected network:

- Line voltages are √3 times of phase voltages.

- Line currents and phase currents are equal.

- Line voltages are separated by 120 degrees.

- Line voltages are always 30 degrees ahead of respective phase voltages.

Advantages of Star Connection

- Minimizes stress and improves motor performance by supplying the motor windings with a balanced voltage supply.

Applications of Star Connection

- Ideal for applications requiring a smooth start or those with varying loads.

- Utilized in motors that drive blowers, fans, pumps, and other machinery that needs to run steadily and effectively.

Safety Measures in a Star Connection

- Before making any connections, make sure the motor is turned off from the power source.

- To prevent erroneous wiring, double-check connections towards the motor’s markings or instructions.

- If unsure about the connections or have complicated wiring, think about engaging a certified technician or electrician.

What is a Delta Connection?

A delta connection, denoted by the Greek character Δ, involves connecting a three-phase motor’s three terminals in a triangle loop.

Step-by-Step Procedure for Delta Connection

Motor Terminal Identification (U, V, W)

When a motor has a delta connection, its U, V, and W terminals are linked to the terminal next to them to create a closed loop that resembles the Greek letter Δ.

Terminal Connections for Delta Arrangement

Connect the ends of coil U1 to the ends of coil W2, coil V1 to U2, and finally the ends of coil W1 to V2 to form a delta connection. The image below shows the delta connection arrangement in an electric motor.

Electrical motors are usually connected in a star or delta configuration depending on the input voltage, but it is also feasible to start the motor in a star-delta configuration. For this, the delta motor voltage rating must be identical to the engine’s supply voltage.

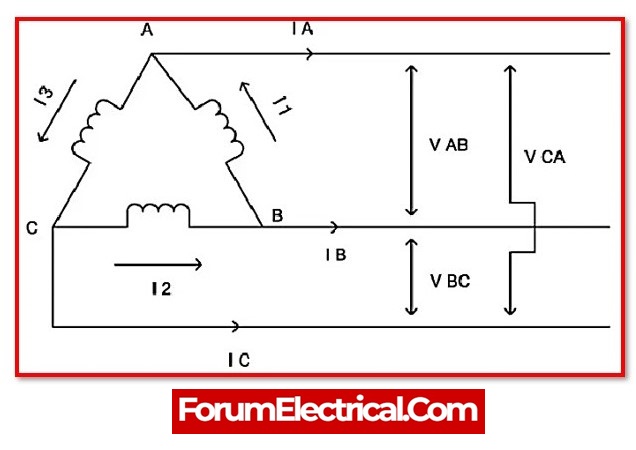

The different ends of the three-phase windings are linked together in a delta connection.

Because only one phase is included between any pair of line outers in delta, the potential difference between the line outers is referred to as the line voltage and is equal to the phase voltage.

VL=VP

Where,

VL – Line Voltage and

VP – Phase Voltage

The following points are noteworthy in the case of the delta connection system.

- Line voltages and phase voltages are equal.

- Line currents lag behind phase currents by 30 degrees.

- Line currents are separated by 120 degrees.

- Line currents are √3 times phase currents.

Advantages of a Delta Connection

- This connection type is more appropriate for applications that need fast acceleration since it has a higher starting torque than star connections.

- Because of its wiring arrangement, less copper is used, which frequently results in cost savings.

Applications of a Delta Connection

- Utilized in motors intended for high-torque applications, including elevators, conveyors, and some machines with a high starting torque requirement.

Safety Measures of a Delta Connection

- Before starting any wiring, make sure the motor is unplugged from the power source.

- To make sure the connections are proper, double-check the wiring using the motor’s handbook or labeling.

- In case uncertain about the wiring or have complex connections, it is advisable to consult a trained electrician or technician.

What are the differences between Star & Delta connections?

Star Vs Delta Connections

| Category | Star Connection | Delta Connection |

| Voltage | The phase voltage is lower when compared to the delta connection. | The phase voltage is higher when compared to a star connection. |

| Current | Because of the lower phase voltage, the line current is higher than in the delta connection. | The line current is lower than in a star connection. |

| Torque | When opposed to the delta connection, it provides less starting torque. | When compared to a star connection, it provides higher starting torque. |

| Torque Application | Suitable for applications that require constant torque & moderate starting torque. | Utilization requiring high starting torque, fast acceleration, or large loads are ideal. |

| Efficiency | Provides efficiency and stability when conditions require moderate starting torque. | More efficient in applications requiring high starting torque, yet may cause motor stress if operated continually at high torque. |

| Performance | Utilized in conditions when the motor windings require a balanced voltage source. | Ideal for conditions requiring quick acceleration or managing heavy loads. |

When should utilize Star and Delta?

- When more current and a neutral point are required, the star connection is utilized, but when high voltage is required, the delta connection is used.

- In general, the star connection with neutral is used for distribution and the delta connection for transmission.

What happens if a delta-connected motor is connected to a star connection?

Because line voltage is√3 times phase voltage and line and phase currents are equivalent, a star connection is typically utilized for higher voltage ratings and lower current ratings. Because line and phase voltages are identical and line current is √3 times phase current, the delta connection is utilized for lower voltage and higher current ratings. The preceding two statements assume a balanced three-phase power supply and equal power output for both the star and the delta.

Also, the line current will be √3 or 1.732 times higher, resulting in higher line loss and, in certain situations, insulation failure. Because the load’s power is the same as the torque, the speed becomes three times the rated value, which may cause severe damage to the load. Over-speeding may cause rotor damage.

As a result, under normal working conditions, the star or delta connection should not be modified.

Which of the three-phase connections, star or delta, has the greater power handling capacity?

The majority of motors are intended to run constantly in delta connection. In a delta connection, they deliver rated power. They are operated in start connection during start-up to reduce starting current. When the motor is nearing rated speed, the connection is changed to Delta since the delta connection has better power delivering capacity.

Motors with lesser power ratings are only designed to work in a star connection. These motors only have three connections.

Why is there no neutral wire in a delta connection?

The phasor sum of all line currents is the current in the neutral wire. When all currents and power factors are equal in a balanced system, the phasor sum of all line currents equals 0A. So, in a balanced system, there is no need for a neutral wire.

What is the formula for a three-phase motor’s star connection?

Three-phase power, voltage, and current values for the Star Connection (Y)

VL = √3 VPH (or) VL = √3 EPH

Line voltages (VL) are 30° leading ahead of their equivalent phase voltages.

How to choose between a Star and a Delta Motor Connection?

Because delta connection generates a higher power and initial torque, the delta connection is utilized to the motor.

However, the starting current is high. In normal operation mode, a star connection is employed when want to slow down the motor starts to speed up & connect to the delta.

Why are Star and Delta Connections used in three-phase circuits?

Star and Delta connections have distinct advantages. Usually, have a neutral point in star, and we can also see the line current & phase current more easily. The delta connection has a higher voltage tolerance than the star connection.

However, it can combine the benefits of both star & delta connections in a particular type of wiring known as zigzag wire.

What makes Star Connection preferable than Delta?

Star connections are mostly utilized in power transmission networks for longer distances, whilst Delta connections are mostly used in distribution networks for shorter distances. Each winding in the Star connection receives 230 volts, while each winding in the Delta connection receives 415 volts.

Application of the Star and Delta Connection

- In general, a star connection is utilized when a neutral and two different voltages are required, like in a distribution system.

- Delta connections are often preferable when a neutral conductor is not required, such as when transmitting high voltage power. In addition, delta connections are recommended when controlling 3rd harmonics.

- When it comes to three-phase systems, star & delta connections are quite widely employed.

- 3 phase transformers are commonly connected in various combinations of star & delta connections.

- As an auto transformer, a star-star connected transformer is commonly employed.

- In general, delta-delta linked transformers are utilized for the high voltage transmission.

- In most conditions, a delta-star connected transformer is utilized as a distribution transformer.

Codes and Standards

- IEC 60034-1 (Rotating Electrical Machines – Part 1: Rating and Performance)

- IEC 60204-1 (Safety of Machinery – Electrical Equipment of Machines – Part 1: General Requirements)

- NFPA 70 (National Electrical Code – NEC)

- IS 325 (Three-Phase Induction Motors – Specification)

- IEC 60947-4-1 (Low-voltage Switchgear and Controlgear – Part 4-1: Contactors and Motor-Starters)

Summary

There are two ways to connect a three-phase system: Star or Delta.

Line to line current in a star connection is equal to line to neutral current. However, the voltage between lines is equal to the root of three times the voltage between lines and neutral.

Each element’s voltage across a delta connection is equal to the line voltage. However, the current passing through each element is tripled by the root of the line current.

The equal amount of power is transmitted by both connections.