- STAR – DELTA Starter

- Star Delta Starter Components

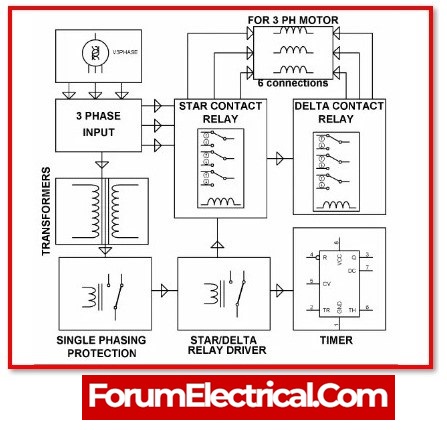

- Star-Delta Starter Circuit Diagram and Working Principle

- Acronyms (Abbreviations) of Star Delta Starter Connections

- Transient States of Star Delta Starter

- Star-Delta starter Types

- Star-Delta starter (motor starting) Characteristics

- Features of the Star-Delta starter

- Advantages of a Star-Delta starter

- Disadvantages of a Star delta starter

- Application of a Star delta starter

- What are the reasons for not utilizing a star delta starter with HT motors?

- When it comes to a star-delta starter, what is the intended function of the delay?

- Difference Between Star-Delta Starter and Soft Starter

- Star Delta Starter vs Soft Starter

- Relevant Codes and Standards

- Some Useful Questions

STAR – DELTA Starter

The Star Delta starter is the most basic starting method for minimizing the inrush starting current of an induction motor. For typical operation, the starter can be utilized with all squirrel-cage induction motors that are delta connected.

The decrease of the high motor current reduces the motor’s starting torque. Star-delta starting is thus particularly ideal for drives that are not loaded until after starting. The starting time is longer than with direct starting, which is noticeable when driving higher inertial loads.

To limit starting current, a reduced voltage starter is required to start a large motor. The star delta starter is a lower voltage starter that applies 1/√3 voltage during the starting process.

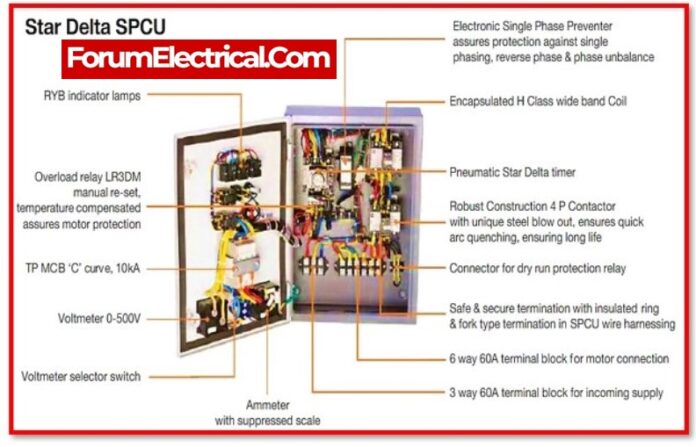

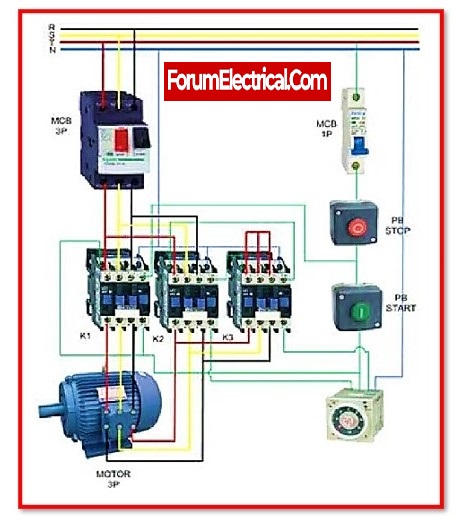

Star Delta Starter Components

The following are the primary components of a wye-delta starter:

1. Contactors

2. Overload Relay

3. Timer

4. The fuse unit

5. MCB

1. Contactors

A contactor is a high-current-rated heavy-duty relay used to power the induction motor. Contactors have current ratings ranging from 10A to several hundred amps.

Usually, most often use three contactors in wye-delta starters, which are as follows:

- The primary contactor

- Delta contactor

- Star contactor

The main contactor & delta contactor are AC3 type and rated at 58% of the motor’s current rating. During the operation of the induction motor, these contactors are closed.

A star contactor, on the other side, only carries star current when the motor is turned on. Because the starting current is 1/3 the rated current, the star contactor can be of the AC3 type and 33% of the full load current rating.

Because these contactors only control winding current, which is 33% of the full load current in the star delta starter, the three contractors used in the star delta starter are smaller than the single contactor used in the DOL starter.

2. Overload Relay

As with induction motors, the majority of winding failures are caused by overloading, operating on an unbalanced voltage supply, and single phasing owing to phase loss, which can lead to excessive heating and motor winding insulation degradation.

To prevent windings against overloading and short circuiting in the internal winding, overload protection is required. As a result, the 3-pole thermal overload relay prevents all of these circumstances.

3. Timer

The timer in the wye-delta starter’s fundamental function is to switch the contactor from star to delta when the motor reaches almost 80% of full load speed.

4. The fuse unit

Three fuses are connected in series with the motor circuit to protect it against external overcurrent and short circuit faults. In addition, one fuse is used to protect the wye-delta starter’s control circuit.

5. MCB

A circuit breaker is an electrical switch that operates automatically to protect an electrical circuit from harm caused by excess current from an overload/short circuit. Its primary function is to interrupt current flow when a problem is identified. In addition a fuse, which can only be used once before needing to be replaced, a circuit breaker can be reset to resume regular operation.

In the star delta starter motor circuit, an MCB is utilised to protect the motor from short circuit circumstances and to prevent motor winding damage.

6. Push-button Start (NO)

7. Push button Stop (NC)

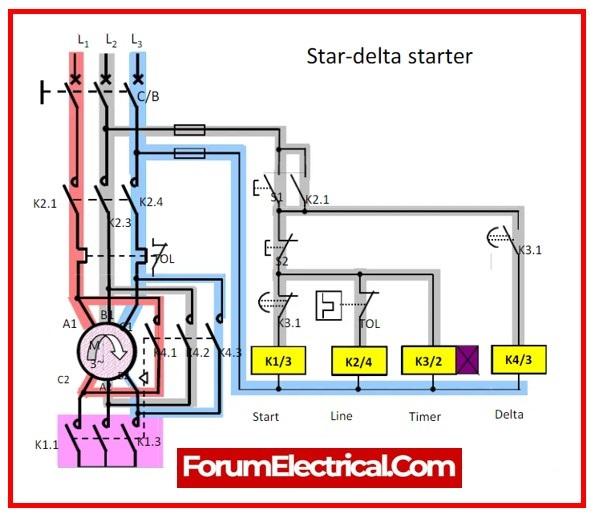

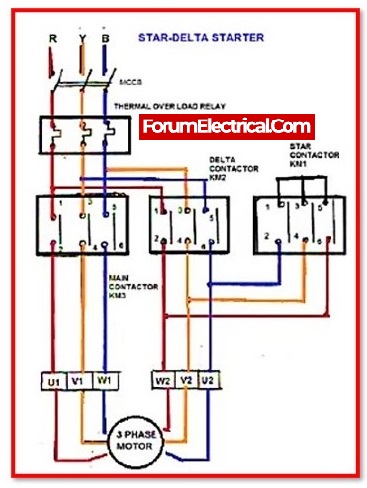

Star-Delta Starter Circuit Diagram and Working Principle

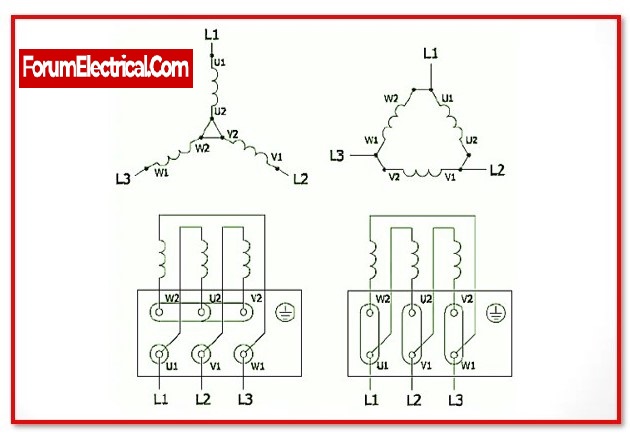

The diagram illustrates the connection of a three-phase induction motor with a star-delta starter. The star-delta starter is a common type of starter that is widely used to start squirrel cage induction motors. It is used to start a squirrel cage induction motor that is meant to function normally on a stator winding that is delta linked.

The stator windings are connected in star when the switch S is in the START position. When the motor reaches 80% of its rated speed, the changeover switch S is thrown to the RUN position, connecting the stator windings in delta.

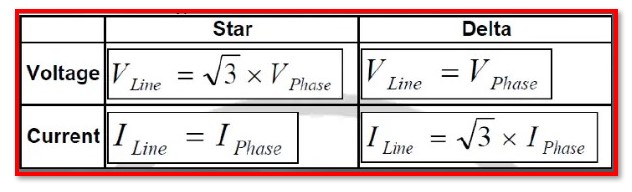

The line current generated by the motor at starting is decreased to one-third of the starting current with the windings linked in delta by connecting the stator windings first in star and then in delta. When the stator windings are connected in a star at the start, each phase receives a voltage equal to 𝑉𝐿/√3, where VL is the line voltage.

Because an induction motor’s torque is exactly proportional to the square of the applied voltage, the star-delta starter reduces the starting torque by one-third when compared to direct-delta starting.

Stator windings are connected in a star connection, and when speed hits 80%, it flips from star to delta using a triple pole double throw (TPDT) switch.

This toggle switches the stator winding from the star to delta. During the starting condition, the stator windings are connected in the shape of a star. Now we’ll look at how a star delta starter can assist a 3-phase induction motor to minimize its starting current.

Consider the following:

VL – Supply Line Voltage.

ILS – Supply Line Current.

IPS -Winding Current per Phase, &

Z – Impedance per phase winding (At stationary).

The winding current per phase (IPS) equals supply line current (ILS) since the winding is star-connected.

IPS=ILS

Due to the star connection, the voltage across the winding’s individual phases is

VL/√3

Thus, each phase winding current equals

IPS =VL/√3Z

Since the supply line current (ILS) and the winding current per phase (IPS) are equal in this case, we may generate,

IPS = VL/√3Z↔ILS = VL/√3Z

Let’s now examine the condition in which the motor is started using the same three-phase supply terminals and a delta-connected stator winding.

Consider the following:

ILD – Supply Line Current.

IPD – Winding Current per Phase, &

Z – Impedance per phase winding (At stationary).

Due to the delta-connected winding, the supply line current (ILD) is equal to 3 times winding current per phase (IPD).

ILD= √3IPD

The voltage across the winding’s individual phases is because the winding is delta connected.

VL

Consequently, each phase winding current is

IPD= VL/Z

Now that can be expressed as,

ILD= √3IPD= √3VL/Z

By comparing the currents drawn from the supply line by an induction motor with the star & delta-connected winding, we are able to obtain the following:

ILD/ILS= √3VL/Z/VL/√3Z=3

ILS= (1/3)ILD

Thus, in the case of a star delta, the starting current from the primary is one-third that of direct switching in delta.

Again, we know that an induction motor’s starting torque is directly proportional to the square of the voltage applied to the winding per phase.

(Starting torque in a stator winding motor with a star connection) /(Starting torque in a stator winding motor with a delta connection)

=(VL/√3)2/VL2=1/3

According to the equation, the starting torque generated by the DOL starter is reduced to one-third by the star delta starter. The star-delta starter can be considered as a 57.7% tapping autotransformer.

Thus, when starting, the current in the motor’s winding is decreased to one-third of its rated value, and the starting torque is reduced to 33%.

Acronyms (Abbreviations) of Star Delta Starter Connections

- L1 – brown, L2 – black, and L3 – blue (3 phase lines).

- CB / MCB / MCCB – General Circuit Breaker

- Main – Main Supply

- Y – Star

- Δ – Delta

- T – Timer

- K1, K2, K3, K4 – Contactors

- O/L – Thermal Overload Relay

- NO – Normally Open

- NC – Normally Closed

- K1/NO – Contactor Holding Coil (Normally Open)

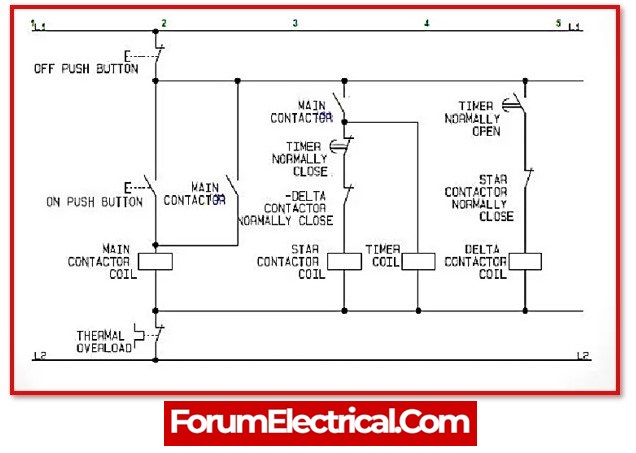

Transient States of Star Delta Starter

The operation of a star delta starter can be simply understood using three different states:

1. Star connected state

During the start-up process, the main contactor and star contactor will be near together to complete the power circuit.

In this state, the induction motor stator winding will be connected in star, reducing the voltage across the motor winding to 1/3 of the line voltage.

When the motor reaches 80% of its full load speed, the timer circuit disconnects the star contactor first and then connects the delta contactor to the circuit.

2. Open transition state

The contactor circuits open during the transfer from star to delta, and the motor remains neither in star nor in delta mode. As a result, this is referred to as an open transition state.

3. Delta connected state

The motor shifted from star to delta when the timer was activated. The phase voltage of a delta-connected state stator is equivalent to the line voltage. As a result, line voltage appears across the stator winding, and the motor operates normally at its rated full-load speed.

Star-Delta starter Types

- Manual Star-Delta Starter

- Semi-Automatic Star-Delta Starter and

- Automatic Star-Delta Starter

1. Manual Star-Delta Starter

The Manual Star Delta Starter is an ideal choice for oil mills, flour mills, and agricultural industries. Superior design by a contractor, with a transient Star Position, assures a smooth transition.

This is the most cost-effective alternative to conventional starters while maintaining the same reliability and protection. Because of the wide band operation coil, it is suited for field circumstances with significantly changing supply voltage.

2. Semi- Automatic Star-Delta Starter

Semi-Automatic Starter (SASD) is a time-tested and extremely reliable starter that is ideal for a wide range of agricultural and industrial applications. It protects the motor from overload, single phasing, phase reversal, and severe unbalanced voltage circumstances.

3. Automatic Star-Delta Starter

Automatic Star Delta Starters have three contactors, an overload relay or circuit breaker, and a timer for setting the Star position (starting position). The Star Delta Starter requires a motor to be in delta connection during normal operation. When the motor is idle, all the rotor bars create a closed route, like a short-circuited transformer. This will increase rotor current flow. Start-up draws 8-10 times the rated current from the stator. Reduce the motor’s voltage before starting it. In a Star connection, the line voltage is three times the phase voltage. So, starting a motor in star reduces voltage and current. In delta connection, the voltage is the same as phase voltage, so the motor receives full voltage. The Star/Delta Starter is comprised of three contactors, a pneumatic timer, and a thermal overload relay or circuit breaker for 440-volt, 50-Hz 3 phase motors.

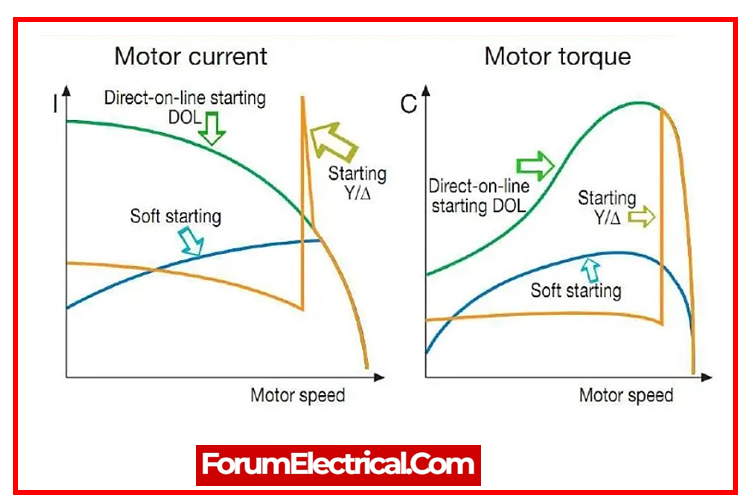

Star-Delta starter (motor starting) Characteristics

- 33% of maximum load current is available as starting current.

- Peak starting current ranges from 1.3 to 2.6 times full load current.

- Peak starting torque is 33% of maximum torque.

- Star-delta starting is recommended for motors that start on no load or have a low load torque with a progressive build-up.

- In a star connection, the starting torque is reduced to one-third of the direct starting torque, or approximately 50% of the rated torque.

Features of the Star-Delta starter

- Star delta starters can only be used for low to high power ratings3-phase squirrel cage induction motor

- The induction motor terminal box requires six connection cables.

- Reduced starting torque.

- Reduced starting current.

- Current peak on the change-over from Star to Delta.

- Mechanical load during the Star-to-Delta changeover.

Advantages of a Star-Delta starter

- It is less expensive than other low-voltage induction motor starting methods.

- The torque and current characteristics of the star delta starter perform better than any other starting methods.

- The starting current is one-third that of the direct online (DOL) starting current.

- There is no need for a tap changing device to be used.

- It generates a lot of torque per ampere of line current.

- The star delta starter’s design and operation are simple and efficient.

Disadvantages of a Star delta starter

- Star delta starters are only useful for motors with six motor terminals.

- For Delta connections, the supply voltage should be the same as the rated motor voltage.

- Because the starting current is lowered to approximately 1/3 of the nominal current, the starting torque is also reduced to 1/3.

- From the starter to the motor, two sets of cables are required.

- If the motor is overloaded, there will not be adequate torque to accelerate the motor to the appropriate speed before switching to the delta position.

Application of a Star delta starter

- For low to medium voltage and low torque squirrel cage induction motors, the star delta staring method is commonly preferred (SCIM).

- Centrifugal compressors also use star-delta starters.

- It is suitable for application where the starting current is low and the line current drown is low.

- It can be utilised in industries such as textiles, food and beverage, sugar plants, paper and printing, cold storage etc.

What are the reasons for not utilizing a star delta starter with HT motors?

For heavy-duty machinery, HT motors are typically recommended. To do that, a soft start and a high starting torque are required. Wound type induction motors with external resistance are often preference in these conditions.

Although high stator voltage squirrel cage motors are still usable, the corresponding Star-delta system would need to be extremely expensive and complex because it involves high voltage switching inside the circuit.

When it comes to a star-delta starter, what is the intended function of the delay?

A star-delta starter’s delay is designed to make it easier for high-torque induction motors to move from the star connection which permits lower voltage and, consequently, lower starting current to the delta connection which provides full voltage for the normal operation.

In order to control starting current, minimize torque, and protect against unexpected mechanical strain on the motor and any attached equipment, the motor is first connected in the star configuration during the starting phase. In the starting, there is less voltage and current, enabling it to avoid overheating and damage.

The star-delta starter’s delay gives the motor time to attain a specific speed by allowing it to accelerate progressively while in the star connection. The starter converts the motor from star to delta configuration following the delay period. The motor can function well and deliver the necessary torque for its intended use by switching to full voltage & full power in a delta connection.

A star-delta starter’s delay essentially provides a smooth and regulated transition from low voltage starting to high voltage operation, enhancing motor performance and shielding it from unexpectedly high currents during starting.

Difference Between Star-Delta Starter and Soft Starter

Star Delta Starter vs Soft Starter

| Category | Star-Delta Starters | Soft Starters |

|---|---|---|

| Number of States | The only two states that a star delta starter can be in are low voltage and full voltage, and the starter can switch between these two states. | On the other end, soft starters increase their rate of start-up gradually. |

| Handling variable loads | It is not possible for star-delta starters to contend with various load conditions. | There are a wide range of load conditions that soft starters are able to manage, including loaded and unloaded starts. |

| Starting time | Star-delta starters, on the other end, do not enable to manage the starting time; star-delta starters have a starting time of three to seven seconds. | Soft starters enable to manage the starting time; they feature a variable starting time ranging from one to about 60 seconds. |

| Torque control | The starting torque of star-delta starters cannot be adjusted. | Soft starters also provide dynamic torque control, allowing to modify the torque to account for differences in motor & load characteristics. |

| Soft stop | Star-delta starters do not have the capability of soft stopping. | Certain soft starters that also have the capability of soft stopping. |

| Current reduction with the extremely light loads | Star-delta starters can be able to reduce starting current to a smaller value. | Soft starters cannot be able to reduce starting current to a smaller value. |

| Simplicity | The design of star delta starters is more complex than that of soft starters. | Soft starters are also simpler to install than standard starters. |

| Power Loss and Open Transition | There is an open transition between the star & delta connections in star-delta starters, which may result in the current transients & excessive torque. During this changeover, the power supply is additionally lost. | There is no corresponding open transition & no power loss with soft starters. |

| Cost | Star- Delta cost less when compare to soft starters | Although they are more efficient, soft starts are more expensive than star-delta starters. |

| Applications | Star delta starters are appropriate for starting low-power machines with load, medium-power machines without load, low-power fans, and low-power centrifugal pumps. | Soft starters can be utilized with significant motors, both loaded and unloaded, such as those used in fans, compressors, pumps, mixers, agitators, mills, and other applications. |

Relevant Codes and Standards

Star-delta starters lower the starting current of the induction motors. Star-delta starting standards typically include requirements for design, testing, performance, & safety. Some major standards are:

- IEC 60947-4-1: Low-voltage switchgear and control gear, Part 4-1: Contactors and motor starters. This standard establishes the specifications for low-voltage motor starters, including star-delta starters.

- IEEE C37.20.1: Standard for Metal-Enclosed, Low-Voltage Power Circuit Breaker Switchgear. This contains rules for the design and operation of motor control centers (MCCs), which frequently contain star-delta starters.

- NEMA ICS 2: Industrial Control & Systems: Controllers, Contactors, & Overload Relays (NEMA ICS 2) Rated 600 volts. This National Electrical Manufacturers Association standard specifies the design & performance of motor starters, including star-delta combinations.

These standards make sure that star-delta starters are safe, dependable, and work properly under a variety of operating circumstances. They address electrical & mechanical endurance, thermal performance, & electrical fault protection.

Some Useful Questions

1. What is the purpose of the star-delta starter?

The Star/Delta starter is probably the reduced voltage starter that is used the most frequently. They are employed as a technique of reducing the disturbances & interference on the electrical supply in an attempt to reduce the start current that is applied to the motor during the starting process.

2. How many HP employ star-delta starter?

A Star Delta starter is utilized so that the starting current drawn by the motor can be reduced. In most cases, it is utilized in associated with induction motors that have more than 5 horsepower (HP).

3. Where is the star-delta starter employed?

The most frequent method for starting a three-phase induction motor is with a star delta starter. During the starting period of star delta starting, an induction motor is connected in via a star connection. Once the motor has reached the desired speed, it is linked in through a delta connection.

4. What are the advantages of using a star-delta starter with an induction motor?

The main advantage of employing a star delta starter is that it reduces current during motor starting.

- The beginning current is reduced to 3-4 times that of direct online starting.

- As a result, the starting current is reduced, and the voltage drops during motor starting in systems are reduced.

5.Which is higher, the Star or the Delta connection?

Due to a 1/√3 of the voltage, the motor speed is slow with a star connection. Because each phase receives the total of the line voltage in a delta-connection, motor speed is high. The phase voltage can be as low as one-third of the line voltage in star connection. The phase voltage equals the line voltage in delta connection.