This post examines over how to choose an electric motor based on speed, power, and torque. One of the most difficult tasks is motor selection.

This post explains in detail about how to select the motor for different applications with these considerations.

Electric Motor

An electric motor is a device that transforms electrical energy to mechanical energy. A typical electric motor has two basic components: the stator & the rotor. The stator is the motor’s fixed component, while the rotor is its moving component.

An electric motor is used to power mechanical loads such as a

- Pump,

- Fan,

- Compressor, and so on.

Electric motors are grouped into the following primary categories based on their power supply and construction:

These motors are commonly utilized to drive mechanical loads in industrial & other applications. The selection of an electric motor for a certain application is dependent on

- Speed,

- Torque, and

- Power.

Let examine at how to choose an electric motor for a given application based on these three factors.

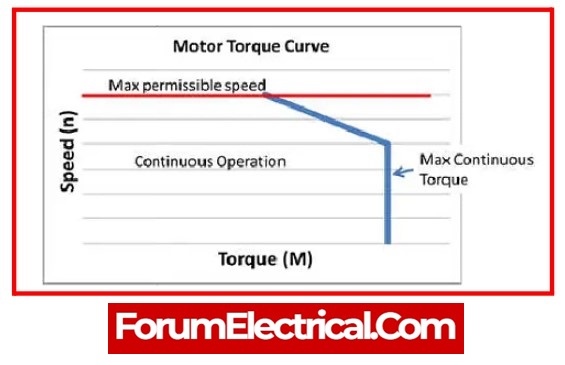

Speed-Based Motor Selection

The method must be followed when choosing an electric motor for a specific application where rotational speed is an essential measuring unit.

The rotational speed necessary for the specific application needs to be initially determined. For example, there may be a condition where a variable speed motor with a variable speed range (or) a constant speed motor is required.

The next stage is to establish the essential features of the load linked to the motor that may impact the motor’s performance, such as the

- Load’s inertia,

- Friction coefficient,

- Speed variation, and so on.

Following that, users must determine the minimum & maximum speed values for the application.

Finally, an electric motor must be selected based on all of the specifications established.

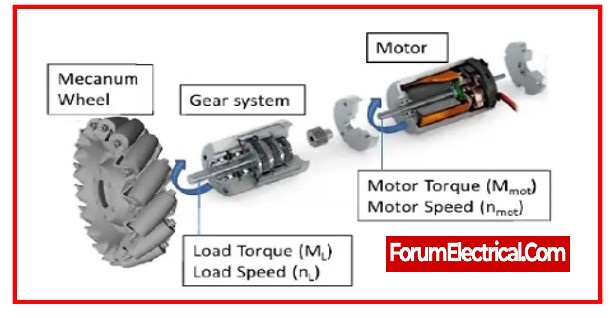

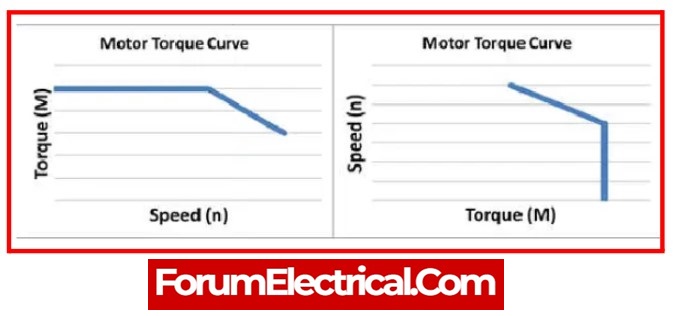

Torque-Based Motor Selection

Electric motors are sometimes chosen for a specific application depending on the torque characteristics of the connected load. Because of the high load inertia, an electric train, as example, needs a high starting torque.

The data provided below will assist in choosing an electric motor depending on torque needs.

Determine the torque characteristics of the load to be connected to the motor shaft first. Determine the minimum & maximum torque for the motor to run smoothly. It is also recommended that industry include a safety buffer of 10% to 20% to avoid overload conditions caused by load changes.

Power-Based Motor Selection

The power generated by the electric motor is an essential factor for generating the necessary output.

For selecting an electric motor based on power generated, the needed power must be determined based on the application & load. Along with power calculation, the motor’s efficiency must be determined in order to decrease energy consumption and running costs.

Then choose an electric motor that accomplishes the power and efficiency requirements.

Selecting the Right Electric Motor: Navigating Power, Speed, and Torque

| S.No | Electric Motor | Speed | Torque | Power |

|---|---|---|---|---|

| 1 | DC Motors | DC motors are characterized by efficient and accurate speed control. As a result, if the load needs necessitate changing speeds, industry should go with a DC motor. | DC motors, especially DC series motors, are ideal for applications requiring strong starting torque. They additionally provide effective torque control. As a result, if the application demands strong starting torque as well as torque variable conditions, DC motors may be the suitable alternative. | DC Motors give great power output control. As a result, if the application needs a variable power output from an electric motor, DC motors may be the ideal selection. |

| 2 | Induction Motors | Induction motors are constant-speed motors. As a result, they are appropriate for conditions in which speed fluctuation is not needed. However, induction motor speeds may be adjusted in a specific range by utilizing a Variable Frequency Drive (VFD) device. | Induction motors are appropriate for applications that need modest starting torque with continuous speed. As a result, if the application load needs are such that speed fluctuation is not crucial and the torque needed is not much greater, induction motors may be the appropriate selection. | Induction motors are usually intended to provide constant torque at constant speed, and hence continuous power output. Induction motors are hence the most appropriate alternative if the load demands steady operating power. |

| 3 | Synchronous Motors | Synchronous Motors always function as constant-speed motors. As a result, they are only appropriate for constant-speed applications. | Synchronous motors are well-known for their steady speed and high torque capabilities. As a result, they are appropriate for driving loads that demand high torque at steady speeds. | Synchronous motors are well-known for generating continuous power output. This is due to their ability to operate at constant speed & torque. As a result, their output power remains consistent. As a result, synchronous motors are appropriate for applications requiring continuous power. |

Conclusion

As a result, this post helps to learn about choosing an electric motor based on power, speed, & torque. One of the difficult challenges in the electric company operations is motor choosing. The companies can choose the best electric motor for their loads with the support of this post.