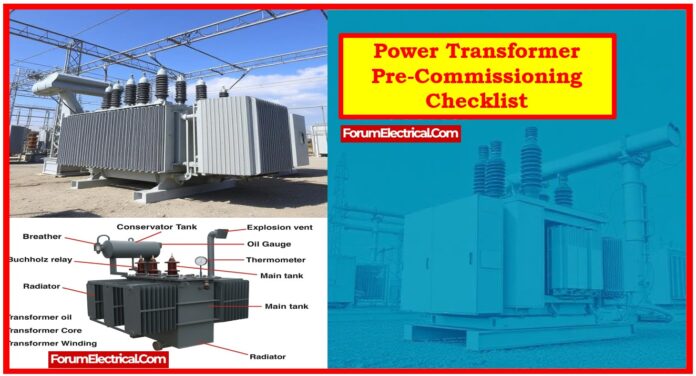

Power Transformer Pre-Commissioning

Pre-commissioning a power transformer ensures its safety, reliability, and readiness for use.

Before energizing the transformer, electrical, mechanical, protection, & control systems are comprehensively inspected and tested.

This comprehensive checklist verifies all essential criteria, from insulation resistance to oil quality & protective relay operation.

This checklist prevents early failures, improves operational safety, and meets industry standards.

Before commissioning the power transformer, it must undergo a thorough inspection.

- Note all details such as ratings, serial numbers, capacity, voltage ratio, and so on.

- Record the serial number, rating, and manufacture of all transformer components, including bushings, tap changer, cooling system, fans, oil and gas driven relays, and temperature indicators. These are essential in terms of maintenance.

- All valves will be tested. Radiator valves, Buchholz relay valves, and so on must be in the open position.

- Check the oil level in the main conservator tank & change the tap in the conservator tank.

- If you’re using sealed bushings, check the oil level.

- Check oil level in the silica gel-breathers oil seal.

- Check the cooling fans, the control connection, and so on.

- Check the connections to the marshalling kiosk, control panel, and control room.

- Verify all protective relay connections and relay settings.

- Check OTI, WTI, and Buchholz relay settings, as well as the operation of the Magnetic Oil Level Gauge, for ALARM and TRIP conditions.

- Inspect the earthing of the neutral, tank, bushing C.T. terminal, and earthing bond between the top and bottom tanks.

- Check the roller wheel stoppers.

- Verify the bushing arcing horn (AH) gap settings.

| Transformer Winding BIL | Arcing Horn Setting (mm) |

| 325 | 380 |

| 550 | 635 |

| 650 | 800 |

| 950 | 1250 |

| 1050 | 1400 |

- Inspect the transformer oil for BDV & water content (ppm) & check that they are within limits.

- Install bushing jumper connections & check for tightness.

To ensure safety, performance, & system reliability, a thorough pre-commissioning inspection and testing process must be completed before power transformers are turned on.

The checklist below includes

- Electrical testing,

- Mechanical checks,

- Protection verification, &

- Operational readiness

for all important transformer and associated equipment components.

Electrical Testing & Functional Verification

All basic electrical testing must yield satisfactory results. This includes the

- Voltage Ratio Test,

- OLTC Continuity Check &

- Exciting Current Measurement

to ensure core and winding health.

The Short Circuit Test & Magnetic Balance Test ensure internal integrity, whereas

- Tan Delta &

- Capacitance Measurements

on windings and bushings assess insulation quality.

- Vector Group Verification,

- Insulation Resistance (IR),

- Polarization Index (PI),

- Breakdown Voltage (BDV) &

- Moisture Content of oil

in both the main tank and the OLTC are all important tests for determining dielectric strength.

Validation of the protection system involves testing of 110kV CTs, HV/LV/Neutral CTs, and various protection relays such as overcurrent, earth fault, differential, REF, master trip relays, annunciation circuits, or supervisory circuits.

Mechanical Inspection & Oil System Readiness

Confirm that the transformer oil fulfills BDV requirements and that the oil levels in the

- Main Tank,

- OLTC Conservator, &

- Bushings

are sufficient.

Clean the bushing surfaces and evacuate air from all bushings & radiators.

All valves, including Buchholz, OSR, & radiator valves, must be correctly installed and functional.

The directional arrows on the Buchholz & OSR relays must point to the conservator.

Breathers must function properly, with silica gel blue & oil bowls filled.

Additional inspections include checking the tightness of test-tap bushings, that explosion vent diaphragms are intact, & that no oil leaks are present.

Critical earthing of the tank, rails, & neutral terminals must be checked.

All external connections must be tightened, & CT secondary terminals that are not already connected should be shorted and earthed.

OLTC & Auxiliary Function Checks

The On-Load Tap Changer (OLTC) should be tested manually & electrically in both local & remote modes.

This comprises raising and lowering instructions, limit interlocks, & emergency actions via the RTCC panel.

The tap position indication should match the real tap positions (usually 01 to 11).

Alarm & trip circuit tests should simulate actual fault events to ensure that

- Buchholz Relays,

- OSRs,

- WTI/OTI Sensors, and

- Other Auxiliary Relays

respond appropriately.

Functional testing must also check that fans operate in both manual & automatic modes, and that standby fans activate when a group fan fails.

Testing Circuit Breaker (CB) & Protection System

Test circuit breaker operations for local/remote closure & tripping, including protection-triggered trips via TC1 and TC2.

Trip circuit (TC) oversight must be confirmed before and after closure.

Anti-pumping relay functionality, lockout conditions, spring failure alarms, & a real CB trip during 86 relay actuation are all necessary inspections.

Open and close times, as well as contact resistance measurement, are part of time-based testing. The CB is then tested for HV.

Protection Checks

Protection coordination must be confirmed with simulated faults & current injections.

Ensure the appropriate operation of 86 relays, intertripping between HV & LV breakers, and the effectiveness of REF & differential protections.

All indication meters (A, V, MW, and MVAR) must be correct.

Check the functioning status of DC and AC fail annunciators, TOD meters, & semaphore indications for isolator & CB locations.

Defect Reporting

Any deviations or non-conformities discovered during pre-commissioning must be reported in the defect list section for further correction prior to final energization.

Standards

- IEEE C57.106: Acceptance & Maintenance of Insulating Oil: Defines BDV & moisture content limits.

- IEC 60076-7: Loading Guide: Provides thermal limits & permissible loading.

- IEC 60076-1: General Requirements: Defines the construction, rating & test requirements.

Checklist

Conclusion

The pre-commissioning checklist ensures the power transformer and systems are ready & reliable.

Validating electrical tests, mechanical conditions, protective schemes, & auxiliary equipment before commissioning helps find and resolve faults.

Prevention improves reliability & reduces downtime, protecting equipment & personnel.

Commissioning is observable & auditable when test results and observations are documented.