Purpose

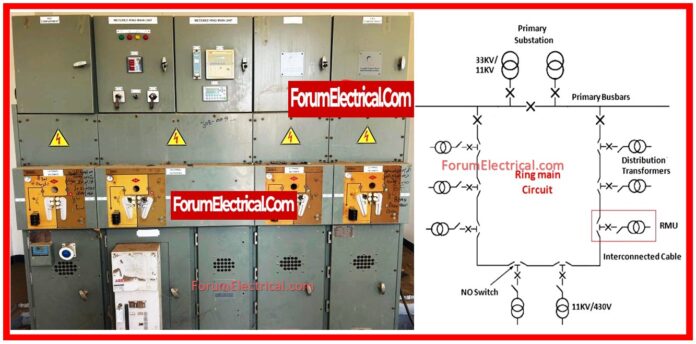

The objective of this procedure statement is to explain the work sequences and procedures that will be used to ensure the proper & safe operation of the RMU and Transformer.

Table of Contents

Scope of Work

Ensure safe operation of RMU & Transformer.

Responsibility

- Project Manager

- Electrical Engineer

- Safety Engineer

Reference

- Project specifications & approved drawings.

- Project Quality Plan.

- Health, safety, & environment manual.

Equipment Required

- Ensure all personnel have proper PPE (Personal Protective Equipment).

- Electrical Safety Shoes

- Flame-Resistant Clothing

- Safety Glasses or Goggles

- Insulated Tools

Precaution

Ensure that the RMU & the space surrounding it are free of any impediments for inspection.

Procedure

Visual Inspection

- Visually check the RMU in search for any indications of damage, leakage, or conditions that are not typical.

- Analyze the RMU for any unnecessary objects which may be present.

Switching Operation

- It is important to adhere to the switching sequence that is specified in the operation handbook.

- When working with switches, make sure you use insulated tools.

- Before starting any work, make sure that proper isolation has been arranged.

Earthing

- Before starting any type of maintenance or switching procedures, make sure that the RMU has been properly earthed.

- Determine whether or not the earthing system is operating appropriately.

| Normal Voltage | Medium Voltage | Low Voltage | Light Current |

| 5 Ω | 2 Ω | 2 Ω | 0.5 Ω |

Communication

- Ensure that there is free and open communication with all of the personnel participating in the operation.

- When it comes to coordination, make use of the existing communication protocols.

Operation Steps of RMU

Turn On

- In the direction indicated by the arrow, turn the earthing switch so that it is disconnected.

- It is clear from the second panel that earthing switch is not connected.

- Place the handle on the panel of the circuit breaker & rotate it in the direction of the arrow, which indicates the direction of the energy storage.

- The final step is to finish the process of closing the ring main unit by pushing the green close button located in upper right corner of the screen.

Turn Off

- The first step is to disconnect low-voltage (LV) main circuit breaker.

- The next step is to click the red stop button that is located in the upper right corner of the circuit breaker.

- It has been determined that the circuit breaker has been disconnected, & the panel indicator of circuit breaker room has displayed the disconnected state.

- The next step is to press the handle into the earthing switch room after inserting it.

- The action of disconnecting ring network cabinet is finished when the arrow rotates in the direction of closing, which indicates that the earthing switch has been closed.

- The panel also indicates that the earthing switch has been closed.

Power Transmission Procedure

- Verify that the primary load switch on the transformer’s output is off before turning it on.

- Remove the “No Switching On” warning sign and open earthing knife lock.

- To open earthing knife, turn counterclockwise.

- Verify that the earthing indication is in the “floating” or off position.

- The earthing knife lock should be locked.

- Unlock the load knife.

- To close the switch, turn it clockwise.

- Verify the three indication lights’ condition.

- Lock the load knife lock.

Power Failure Operating Procedure

- The transformer’s output total load switch needs to be unplugged before the transformer is turned off.

- Check the three indication lights’ condition.

- Unlock the load knife.

- Manually press the red “OFF” stop button until the switch sounds.

- Verify that all three of the indicator lights are white and not flickering.

- Lock the load knife lock.

- Open the earthing knife lock.

- Close the earthing knife by rotating it clockwise.

- Hang up a warning sign that reads “No Switching On” and make sure the earthing indicator is in earthing state.

- Lock the earthing knife lock.

Emergency Procedure

- In the case that any unusual conditions arise, you should be conversant with the emergency shutdown procedures.

- Every member of the staff should be informed of the protocols for responding to emergencies.

Post Operation Inspection

- Once the process has been finished, it is necessary to perform a visual inspection to ensure that all of the switches are in the appropriate position.

- Ensure that all of the precautionary measures have been carried out in the appropriate manner.

Documentation

- Please make sure to document all of the pertinent information pertaining to the operation, particularly any deviations from standard operating procedure.

- Ensure that records are kept for future use and for the purposes of auditing.

Training

- Make sure that all of the staff who are involved in the RMU operations have received sufficient training and are capable.

- Refresher training courses should be offered on a regular basis in order to emphasize safe operating procedures.

Closure

- Protect the RMU & the area immediately surrounding it.

- Make sure that all of the tools & equipment are stored in the appropriate manner.

- Complete any paperwork or reporting that may otherwise be required.