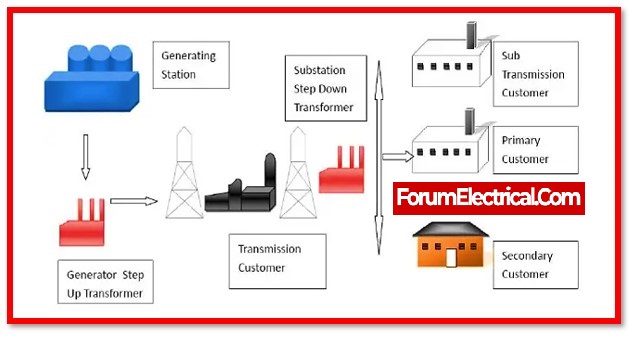

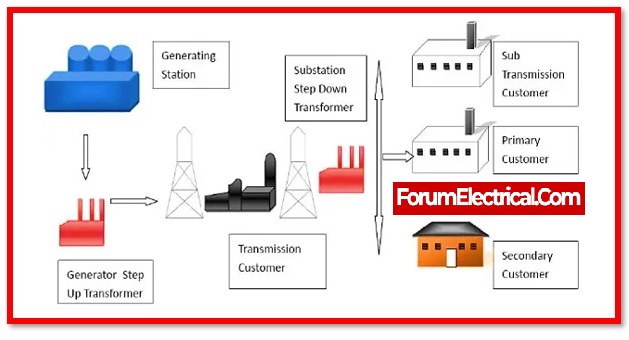

A power system includes

- Generation,

- Transmission, and

- Distribution.

It transforms resources into electricity.

Automation does operations without human talent or labour. It uses automatic processes in labs, households, companies, and research centres. It helps with human-unattainable work. Automation precedes transmission and distribution.

Electric utilities compete to provide competitive power costs. Accidents, lightning, and natural disasters cause power outages. Thus, power systems have to be tracked and managed to ensure fast action and uninterrupted supply of electricity. Therefore, the power system must be automated.

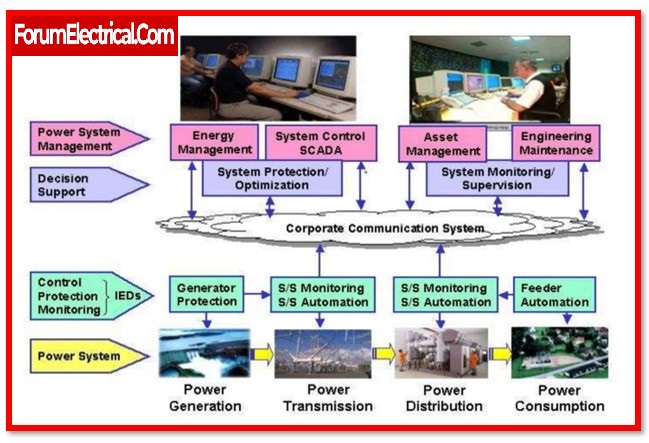

Power System Automation

Automation of the power system refers to the automatic operation of the power system using instrumentation and control equipment. In order to control the components of the power system, substation automation refers to

- Use of data from Intelligent Electronic Devices (IED),

- Control and automation capabilities within the substation, and

- Control instructions from distant users.

Earlier, manual supervision of operational procedures was standard practice. This required the supervisor or operator to be present at the facility all the time, which was not feasible. This issue has been resolved via automation, which can be mechanical, cost-effective, computerized, or a combination.

SCADA and data communication are used for automation at the substation. SCADA data connection is necessary for substation automation in order to regulate, monitor, and protect the equipment and functions. By cutting costs and removing the need for labour, it has a significant impact on the global economy.

Function of SCADA in the Electrical Distribution System

The SCADA system is designed to monitor & control the operation of massive electrical networks in a way that is both safe and dependable. The operator is provided with an all-encompassing perspective of the network as a result of the system’s collection and processing of data that has been transmitted from other substations. Scada is used to monitor an electrical network that distributes electricity generated at a major substation to a wide range of consumers located throughout an area.

The primary substation acts as a feed-act for additional local substations, allowing electricity to be distributed to a residential neighbourhood, an urban commercial district, and a nearby airport. By way of an additional circuit, the principal substation provides power to both a bustling port and a comparatively sleepy rural town.

Control and Monitoring of the Power Automation System

- A programmable logic controller (PLC) and a number of other specialized devices, including as circuit breakers & power monitors, are used to control and monitor a substation in real time.

- Then, the data from the PLC & the devices are sent to a PC-based SCADA node that is positioned at the substation.

- Various centralized control & monitoring stations have one or more personal computers stationed.

- The connections between the personal computers at the substation and the personal computers at the central station are often based on ethernet and are carried out by means of the internet, an intranet, or a form of cloud computing of some type.

- SCADA systems normally permit orders to be given from central control & monitoring points to substations. These commands can enable full remote control of the system.

How SCADA manages & maintains the network during a fault?

During a fault, the SCADA system is utilized to manage and maintain the network in the following ways:

- In a distant and rural part of the network, a tree branch that has fallen creates disruption to the overhead powerline that feeds substation 2.

- This disruption in transmission enables the circuit breaker for this transmission line to trip at primary substation, which ultimately results in a complete loss of power to both the port and the rural population that is dependent on this circuit. The power supply to the remainder of the network is unaffected.

- When the circuit breaker trips, a notification is sent to the SCADA system, which then utilizes the fault passage indicator, which is placed strategically around the network, to establish where the fault has occurred.

- In this particular condition, the fault passage indicator located at substation 2 has not been tripped. Consequently, the operator receives instruction at the distant SCADA data centre that the fault must be located wherever on the line connecting the primary substation & the substation 2.

- The operator can now use the SCADA system to isolate that region, and then they can divert the power to consumers who do not have a supply. The incoming switch at substation 2 is opened by the operator from the remote control of the primary substation.

- After, it flips the valve that connects the rural settlement to the substation 2’s incoming power. The port region will be completely cut off from all other parts of the network as a result.

- The operator is now able to close the outgoing switch associated with substation 3 in order to re-energize the connection to substation 2. It is possible for Substation 2 to restore power to the port.

- In order to prevent one side of the network from becoming overloaded, the operator selects to instead close the switching device on the back feed to the rural village in order to restore the community’s supply.

- The operator is now able to make arrangements for a repair because supplies have been restored to all regions that were impacted and the problematic line has been successfully cut off from the network.

- In most conditions, the network will be sectioned off and the power will be diverted within 30 minutes of the initial problem occurring.

- SCADA gives the operator the ability to directly pin point the precise location on the system where the fault has arisen and fix it.

- Once the operator has received confirmation that the restoration has been completed and that all members of the maintenance crew have left the area, SCADA can be utilized to restore the network to its normally scheduled functioning.

- The completely repaired line is put to the test initially by shutting the primary substation’s outgoing switch to the secondary substation.

- The line returns to its regular level of energization, proving that the repair was successful. Now that the operator has the ability to do so, they can shut off the input switch to substation 2, which will restore the normal supply route. It is no longer necessary to use the back feed from the substation 3.

- The SCADA operator is now able to open the switch that controls the incoming data. As soon as the load was removed from the network’s lowest side, the rural community output switch from substation 2 was closed, which produced a parallel circuit for that region.

- The final process for the SCADA operator is to reset the switch in order to restore the normal operation of the entire network. This will prevent the back-feed from going to the rural community.

Advantages

- Increase in service quality and decrease in the amount of necessary labour.

- Reduced costs associated with operations

- Options for flexible payments and fewer minutes loss to power outages

- Enhanced information accessibility for consumers in order to better facilitate decision making

- Transportable, with reduced expenses for maintenance

- Reduce the number of times that accidents happen.

Disadvantages

- Insufficient number of train personnel.

- Initial investment is quite expensive.

- Warnings alarm causes trouble.