What is Capacitor Bank?

A capacitor bank is an arrangement that stores energy and is comprised up of multiple capacitors that are either connected in series (or) in parallel to form the system.

This system facilitates in rectifying the power factor lag & phase shift that might occur in an AC power supply, hence contributing to an increase in the efficiency of the transfer of electrical energy.

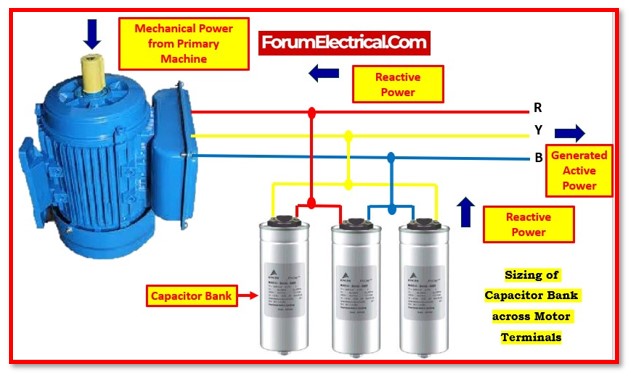

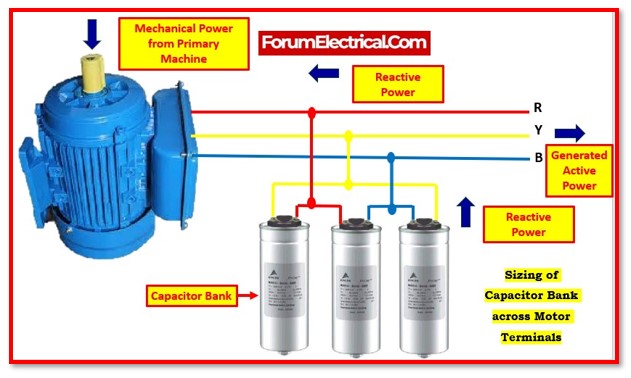

Capacitor bank in motor

Capacitor bank have been installed on individual motors, and also on groups of motors, by engineers as part of an ongoing effort to cut operating expenses.

Advantages of Capacitor Bank across Motor

- Improved power factor, which eliminates or reduces utility demand charges.

- Reduced energy loss in the electrical conductors by lowering the required current

- Capacitors may additionally supply voltage support at various busbars

- Discharge of valuable system capacity and

- Increased lifespan of distribution equipment.

Capacitor size for motor compensation

The capacitor serves as a source of the reactive current in close proximity. In terms of the motor, this reactive power represents the magnetizing current, also known as the “no load current,” which is necessary for the motor to function properly.

When the current rating of a capacitor at full load is equal to at least 90 percent of the current drawn by the motor when it is not under load, the capacitor has been sized appropriately. Because of this rating of 90%, over correction & the difficulties that come along with it, such as overvoltages, are avoided.

1). Known No-Load Current

The current drawn by the motor when it is not under load should be multiplied by 0.90 (90%), which is the most accurate way to choose a capacitor.

2). Unknown No-Load Current

In the condition that the no-load current is unknown, an acceptable calculation for three-phase motors is to determine the full load amps and multiply that number by 30%. After that, multiply that number by the 90% rating value that is being utilized to prevent overcorrection and overvoltages.

Basic Rule: It is accepted that the motor compensation needed in KVAR is equivalent to 33% of the motor rating in horsepower.

Formula

Motor rating after 90% load factor(KW) = Motor Rating x 0.90

Motor full load current IN amps(FLC) = (KW*1000)/(1.732*V*P.F 1*Eff.)

Where,

KW – Rated Motor in KW

V – Supply Voltage

P.F.1 – Motor Power Factor

Eff – Efficiency(%)

- No load current (A) = 0.35 x Full Load Current

- Capacitor bank connected across motor terminal = (1.732 x Supply Voltage x Capacitor Current)/1000

Calculation

Step:1 Enter the input Values

- Motor Rated KW

- Supply Voltage

- Motor Power Factor

- Efficiency(%)

Step:2 Enter No-Load power factor(Assumption) (Default value=0.1)

Step:3 Motor full load current (FLC) and rated capacitor in KVAR to be connected is derived as output.

Motor rating after 90% load factor(KW) = Motor Rating x 0.90