Table of Contents

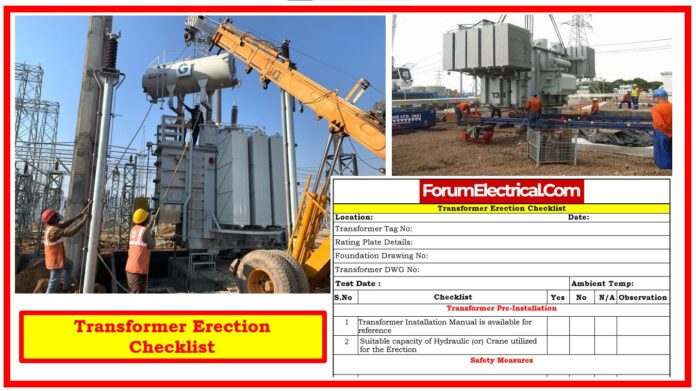

Creating a detailed transformer erection checklist is essential for a smooth, safe, & efficient installation procedure.

This checklist can be customized to the specific type of transformer & site conditions.

Below is a complete checklist that covers the various steps of transformer installation:

Transformer Pre-Installation Checklist

- Ensure that all essential permissions & approvals are in place.

- Consult the manufacturer’s installation manual & technical specifications.

- Ensure that all engineering drawings & site plans are available.

- Site Preparation

- Confirm that the transformer groundwork (foundation) is complete and meets the design criteria.

- Check for adequate grounding & bonding at the jobsite.

- Make sure the location is free of debris and appropriately leveled.

Equipment & Tools

- Check the availability of all required tools & equipment (cranes, rigging gear, and safety equipment).

- Inspect lifting & handling equipment to ensure it is certified and safe.

Safety Measures

- Conduct a safety briefing for all individuals involved in the erection procedure.

- Ensure that all workers have access to and use personal protective equipment (PPE).

- Check the availability of first-aid kits & emergency contact information.

Transformer Arrival & Inspection

- Inspect the transformer for evident damage during shipping.

- Check that all components & accessories are there, as specified on the packing list.

- Document any differences or damages & notify the provider right away.

- Follow the manufacturer’s instructions for unpacking the transformer.

- Ensure that no damage occurs throughout the unpacking procedure.

Pre-Installation Tests

- Perform insulation resistance (IR) tests.

- Conduct oil tests on transformers that are filled with oil.

- Check the tightness of any external connections.

Transformer Erection

- Place the transformer on the foundation in accordance with the layout plan.

- Align the transformer using the appropriate alignment tools.

- Assemble all external components, including bushings, radiators, conservator tanks, and fans.

- Ensure that all components are properly secured and properly aligned.

- Connect primary & secondary cables, or busbars.

- Make that all electrical connections have the necessary torque.

- Install grounding cables per the grounding plan.

- Follow the right process for filling the transformer with oil.

- Perform degassing & dehydration as needed.

- Check oil levels and check there are no leaks.

- After installation, conduct final checks and testing.

Testing

- Perform an extensive visual check of the transformer.

- Perform final electrical testing such as insulation resistance, winding resistance, & ratio tests.

- Check the operation of all cooling systems & control devices.

Commissioning

- Energize the transformer with supervision.

- Check for unusual noises, vibrations, (or) temperature increases.

- Keep a record of all commissioning data for the future reference.

Documentation

- Collect all test results, assessment records, & commissioning reports.

Maintenance and Monitoring

- Schedule regular maintenance inspections based on the manufacturer’s recommendations.

- Evaluate transformer performance & document any irregularities.

Oil Analysis

- Conduct periodic oil sampling & analysis.

- Check the dielectric strength, moisture content, & dissolved gas analysis.

By following this complete checklist, you can assure a methodical and safe transformer erection process, reducing the possibility of errors and assuring long-term reliable operation.