- What Is a Transformer Fire?

- Causes of Fire in Transformers

- Causes to Explode Transformers

- Transformer Fire Protection Requirements

- How Do You Extinguish (Stop) a Transformer Fire?

- 6 Components of a Fire Protection System

- Fire Protection Standards

- How to Test the Transformer Fire Protection System?

- Advantages of Fire Protection Systems

What Is a Transformer Fire?

A transformer fire is a conflagration that starts inside & around a transformer. A transformer is a unit of equipment that transfers electric energy from one alternating current circuit (AC) to another (or numerous others) while changing the voltage. Transformers are an essential component of our infrastructure, having been employed in the modern electrical grid.

Transformers are utilized for two major functions:

- Step down the voltage of a typical power circuit to utilize it in lower voltage devices.

- Increase a generator’s voltage to enable long-distance travel.

Furthermore, two variables increase the probability and danger of transformer fires. The initial factor is the large amount of electrical energy that flows through a transformer, generating a significant amount of heat. The second factor is that many transformers use flammable mineral oil as

- Insulation and

- Cooling fluid.

Causes of Fire in Transformers

Transformer fires are uncommon, but their damage is significant. Even if a transformer involved in a fire is likely to be destroyed practically instantly, the fire’s impact on surrounding equipment and structures can be reduced and hence must be considered.

An uncontrolled fire can cause severe damage & result in a lengthy and unannounced outage.

- Excessive overheating, severe short circuits and oil leakage issues can all cause transformer fires.

- Lightning, severe winds, & other extreme weather events can cause damage to buildings and/or equipment, potentially affecting interior transformers.

- Depending on the transformer, mechanical failures may include cable termination failure, internal arcing, tank ruptures, (or) conductor tipping.

- Transformer fires are also more likely when electrical problems such as power surges, insufficient insulation, and overvoltage exist.

Causes to Explode Transformers

There is an added risk of transformer explosion following electrical fires, regardless of the cause of the sparks and fires in transformers.

This is especially relevant for transformers that coolant and insulator are made of mineral oil. Under certain conditions, the mineral oil might burn quickly and explode.

This occurs when the mineral oil is warmed beyond the point of continuous combustion or when a spark is present (such as in a lightning strike or internal arcing).

Transformer Fire Protection Requirements

- Active transformer fire suppression systems should be installed in new facilities with sizable, mineral-oil-filled transformers close to the plant structure or other equipment. These systems will protect the surrounding equipment and the structure itself, and containment systems that are properly developed will protect the environment.

- To lower the risk of fire and environmental damage, extensive consideration should be given to placing transformers containing mineral oil far from power plant, other equipment, & waterways in new construction and, if applicable, at existing power plants. If other factors permit, aggressive fire suppression might not be required in these conditions.

- To save plant structure & other equipment, existing, working fire suppression systems should be kept in place but should be evaluated for sufficiency and conformity with current codes and regulations.

- After being checked for sufficiency and conformity with current codes and standards, inactive fire suppression systems must be put back into service.

- Where necessary, fire suppression systems need to be added to already-existing buildings to protect other equipment or the plant’s structure.

- Testing, maintenance, & inspection of transformers should be performed on a routine basis, and they should also be subjected to regular condition evaluations. Transformers that have low condition indices ought to be scheduled for replacement or repair.

- In order to limit a fire and explosion and lessen collateral damage, fire walls should be erected where practical and appropriate between nearby transformers, across transformers & the plant structure, across single-phase transformers, (or) across transformers and other equipment.

- Suction system testing, maintenance, and operation must be done correctly.

- All relevant laws, rules, and standards must be followed by containment & oil-water separation structures.

- Transformer access will be restricted to individuals conducting official activities in the surrounding. There will be limits on the public’s proximity to transformers.

- Environmental legislation that apply must be taken into consideration.

How Do You Extinguish (Stop) a Transformer Fire?

In case a transformer fire breaks out, there are a number of standard ways that can be used to manage or put out the fire. This includes:

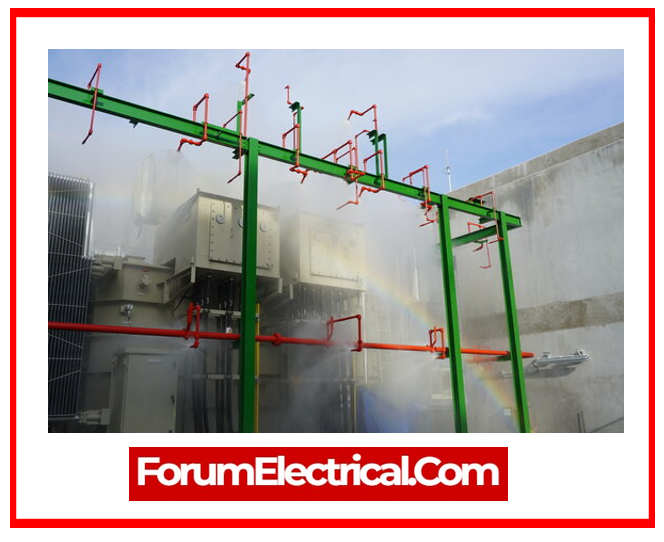

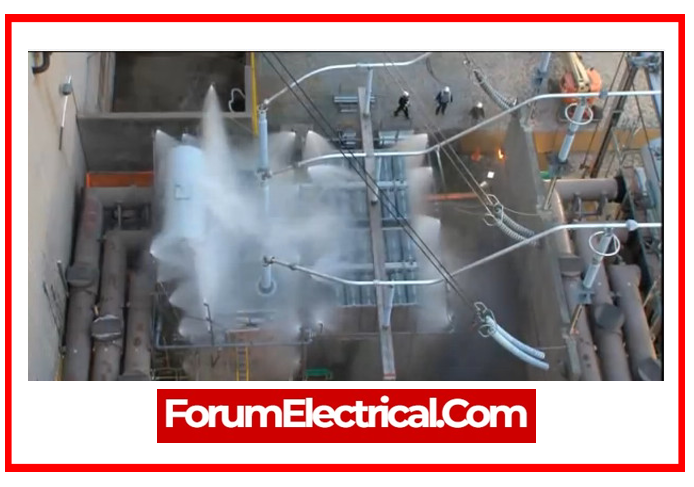

1). Water-Based Systems (Sprinkler System)

2). Direct Release System

3). Indirect Release Systems

1). Water-Based Systems (Sprinkler System)

One technique is to install a sprinkler system around transformers. Depending on the application, there are multiple types of water-based transformer fire prevention systems, such as deluge, fixed water spray, water mist, & pre-action water mist. Water is a frequent suppression method, however it is inefficient, especially in locations where water could damage other electrical systems & equipment.

2). Direct Release System

A direct release suppression system is an alternative to water-based systems that employs a specific suppressant that is compressed in a canister attached to a detecting tube. If a fire starts, the detecting tube degrades, allowing the suppression chemical to be released and swiftly working to extinguish the fire.

3). Indirect Release Systems

An indirect release system operates similarly, except that when the suppressant is released, it is distributed across a much broader area, making indirect release systems preferred in situations when a larger region may be affected.

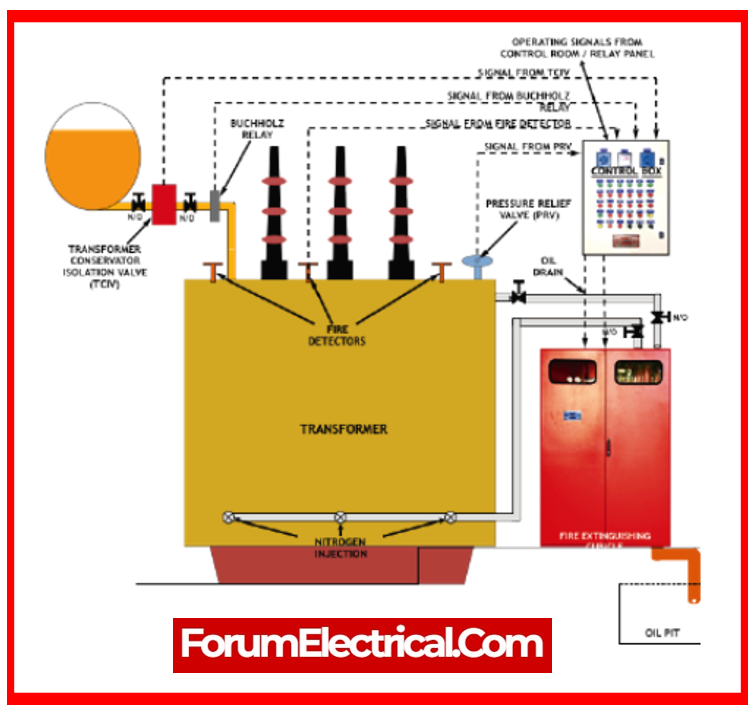

6 Components of a Fire Protection System

- Fire Alarm Activating Devices: These trigger fire suppression systems in the event of a fire. They include gear like sprinkler flow switches & manual pull stations.

- Fire Notification Devices: Fire alarms, strobing lights (or) horns are used to notify building inhabitants that a fire has broken out.

- Alarm Monitoring Systems: These automatically notify fire departments (or) other emergency personnel in the event of a fire.

- Suppressive Delivery Methods: These supply fire suppressive measures to the fire and include equipment such as sprinkler heads and pipework.

- Primary & Backup Power Sources: These generate the power required for active fire suppression systems. Backup power supplies provide functioning during power interruptions.

- Alarm Control Panels: These allow emergency personnel to turn off fire alert devices once a fire has been extinguished.

Fire Protection Standards

If you want to learn about fire-prevention measures for transformers, the NFPA is an excellent source. The group mentioned above publishes transformer fire safety guidelines, which include:

NFPA 70: The National Electrical Code (NEC) is a set of standards established by all 50 states that includes laws and procedures for “safe electrical design, installation, & inspection to protect people & property from electrical hazards.”

NFPA 850: NFPA 850 (“Recommended Practice for Fire Protection for Electric Generating Plants & High Voltage Direct Current Converter Stations”) provides fire safety recommendations for electricity generating plants, converter stations, and combustion turbine units.

How to Test the Transformer Fire Protection System?

The fire protection system is tested in a separate manner.

The following are some of the testing methods used to evaluate the system.

1). Manual activation valve test

3). A valve release system near transformer.

Advantages of Fire Protection Systems

- When a fire catches the transformer, the fire protection system activates, preventing the fire from spreading to other areas.

- This design is highly adaptable and may be used for wide open areas. It is also cost-effective when using water.

- Reduce the fumes, and further pollution enters the air.