Oil dehydration constitutes a part of annual maintenance because moisture content is mixed into transformer oil over time, causing transformer losses to increase.

- What causes Moisture in Transformer Oil?

- What is Transformer Oil Dehydration Procedure ?

- Why is it necessary to Dehydrate Transformer Oil?

- What is Transformer Oil Filtration & Dehydration?

- Equipments Required

- Safety Regulations

- Standards

- Oil Dehydration Procedure

- Initial Procedure

- Dehydration Procedure

- Breakdown Test

- OLTC Chamber Dehydration

Therefore, it is essential to minimize transformer losses.

Initially, we will need to apply the oil dehydration procedure to remove moisture from the transformer oil.

This method starts with an oil breakdown test and then progresses to the oil dehydration process.

How to remove moisture from Transformer Oil?

There are several methods for removing moisture from transformer oil, including employing

- Online dryers,

- Vacuum dehydration, and

- Filtration systems.

These procedures are designed to remove moisture from both the oil and the paper insulation, that has a high moisture affinity.

What causes Moisture in Transformer Oil?

Water is discharged from the surface of the solid insulation & absorbed into oil as the temperature rises due to loading.

During temperature fluctuations, oil and paper exchange moisture continuously.

Hysteresis in the moisture transfer between oil & cellulose throughout temperature fluctuations.

How Water Gets into Transformer Oil?

Water can enter the oil in two different ways:

- 1st – atmosphere.

- 2nd – water from cellulose insulation & oil,

which attains as a result of aging process.

If the transformer is always run at full load, its insulation will age in around 20-30 years.

During this time, up to 0.5-0.75% of the insulation’s weight will be discharged as water.

Water in transformer oil can take the following forms:

The water settled to bottom of cooling tank (free water). Although it does not affect dielectric strength, it is still undesirable because it indicates the presence of solved water in the oil.

Solved water reduces the oil’s dielectric strength and is often introduced from the atmosphere.

Additionally, bound water is a sign of oil aging and oxidation.

Transformer heating converts bound water to vapor, while emulsified water is a combination of transformer oil and submicroscopic water droplets that cannot be separated from oil through heating, settling, (or) filtering.

During the process of dehydration of transformer oil, the concentration of water must be reduced to levels that enable the dielectric fluid is to be utilized indefinitely.

Additionally, the dielectric strength of the oil must be restored to the appropriate parameters.

What is Transformer Oil Dehydration Procedure ?

Transformer oil dehydration is the procedure of removing moisture from new transformer oil (or) transformer oil which has degraded due to prolonged use.

Why is it necessary to Dehydrate Transformer Oil?

In addition to cooling and heat dissipation, transformer oil can be used to suppress arcs at the contact points of the tap changer & the high voltage lead, preventing corona and arc discharge.

At the same time, it provides insulation and maintenance for windings. (Stay adequately insulated).

When transformer oil becomes contaminated with water while in use, the insulating and arc suppression capabilities of transformer oil are compromised, as is the transformer’s regular performance.

Consequently, timely transformer oil dehydration is extremely important.

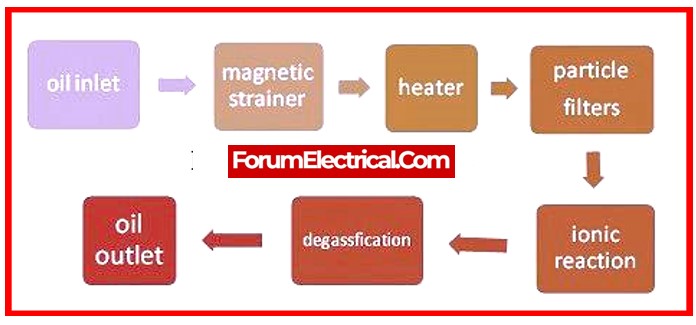

What is Transformer Oil Filtration & Dehydration?

Transformer filtering consists of the dehydration and degassing of transformer oil.

After effective insulating oil filtration, physical & chemical qualities of transformer oil are restored, and it is less expensive than replacing new oil.

Equipments Required

- Top up with fresh transformer oil

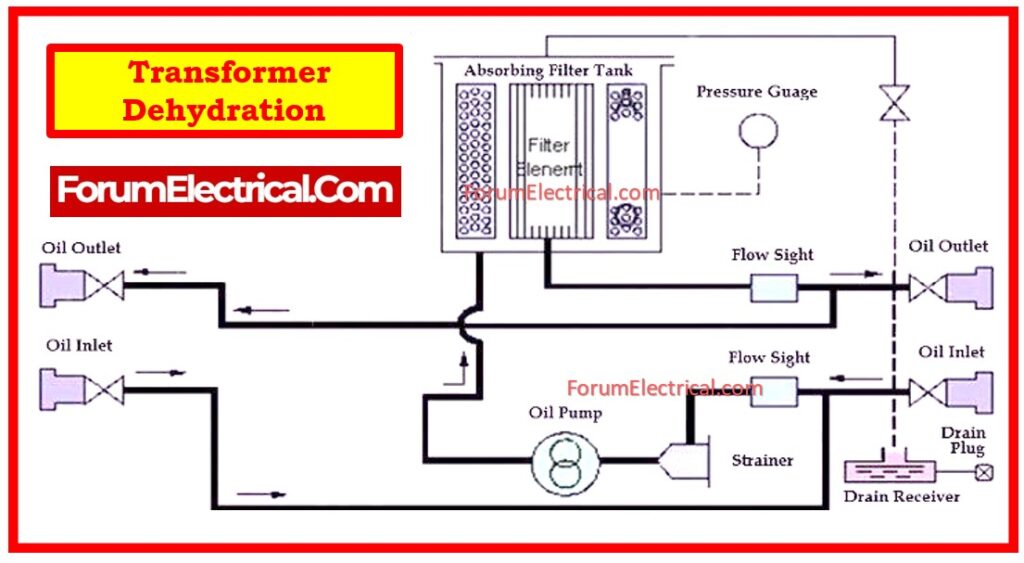

- Oil dehydration machine

- Arrangement of necessary tools

- Oil breakdown testing instrument

- Electrical cables

Safety Regulations

Transformers are electrical static devices that work at high voltages.

Any high voltage leakage can be hazardous to maintenance personnel, so it is especially important to observe the safety precautions outlined below.

- In order to rack out, you must first turn off the HT (High Tension) circuit breaker.

- The HT panel is required to make use of the LOTO capability.

- If you want to avoid oil falling into the floor, you should make use of a floor guard.

- The oil breakdown test must be conducted both before and after the oil dehydration procedure.

- Cable size should be greater than the ratings of the oil dehydration machine.

- Transformer oil must be topped up following the dehydration process.

Standards

- IEC 60296: Specifications for unused mineral insulating oils for transformers.

- ASTM D1816 / D877: BDV test methods.

- IEC 60422: Guide for the supervision and maintenance of insulating oils in transformers.

Oil Dehydration Procedure

Oil dehydration is a procedure that removes moisture from transformer oil. The process details are provided below:

Initial Procedure

- Turned off and racked the entering and outgoing circuit breakers.

- Use the LOTO technique on the transformer’s incoming and outgoing panels.

- Connect dehydration machine to electric panel.

- Connect the dehydration machine’s receiving oil pipe to transformer drain pot.

- Connect the dehydration machine’s oil discharge hose to conservator top-up pot.

- Before starting this procedure, check the oil breakdown value & take observations.

Dehydration Procedure

- Start the dehydration process, and after four to five hours, do the break down test.

- Spare transformer oil must also be dehydrated and topped up in the transformer.

Breakdown Test

- The break down voltage (BDV) must be changed to 50 kilovolts and kept at that level for one minute if the HT supply is 11 kilovolts.

- The breakdown voltage (BDV) must be set to 60 kilovolts and maintained for one minute if the HT supply is 33 kilovolts.

- If the breakdown test passes, the dehydration procedure should be continued for a further hour.

OLTC Chamber Dehydration

- Drain the oil from the OLTC chamber in order that it can be checked and cleaned correctly.

- After cleaning and inspecting, the oil will be dehydrated in the same way as tank dehydration is done.

- Please ensure that the oil breakdown test is performed on the OLTC chamber, which is identical to the oil tank.

- Replacement of silica gel, maintenance of Buchholz relays, maintenance of OTI and WTI, and other similar operations are also included in the list of maintenance activities.

- Immediately following the completion of the dehydration procedure, the transformer needs to be examined for load, sound, & leakage respectively.