- What is an electrical fault in power system?

- Identifying and Troubleshooting Electrical Problems (Faults)

- Identifying Electrical Faults (Problems) With Electrical Systems

- Electrical Fault Identification

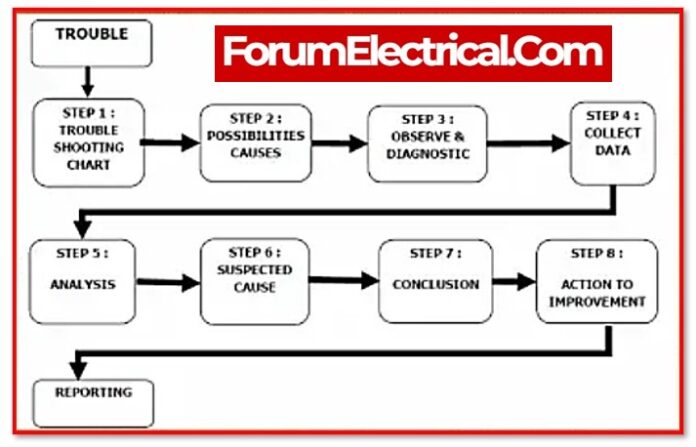

- Procedure of Troubleshooting

- Electrical Troubleshooting Requires the use of Testing Equipment

- Difference between fault finding and troubleshooting

- Importance of electrical troubleshooting

What is an electrical fault in power system?

An electrical fault is an abnormal condition that may be caused by either the failure of equipment or faults in the wiring, and it can result in the wrong functioning of machinery or other devices. Electrical malfunctions have the potential to interrupt the production of a whole line of goods, which may result in significant financial losses.

Electrical malfunctions are normally the consequence of either an open circuit (or) a short circuit, but they may also be the result of a mix of the two of these.

- Incorrect operating voltage,

- Mechanical breakdown of components,

- Excessive heating,

- Corrosion

are some of the other possible problems that might occur.

Identifying and Troubleshooting Electrical Problems (Faults)

Electrical problems constitute the absolute problem of any maintenance & professional that works in the industrial sector. There has been a considerable measure of ability into the process of solving electrical problems.

Identifying Electrical Faults (Problems) With Electrical Systems

1). Open circuit faults

Open circuit faults Generally, a failure of this kind may be detected rather quickly since some component of the circuit will not be functioning properly because it is not getting the voltage that is necessary for proper operation. Check for light bulbs that have burnt out, functioning coils that are open, and loose connections or terminal points as potential causes for this type of problem. On machinery parts that have wire that is constantly bent and flexed, could detect a broken conductor embedded inside the insulation, which results in an open circuit.

2). Short circuit faults

Short circuit faults in most conditions, a short circuit arises when the insulation that surrounds a conductor starts to degrade, which allows the current to make its way to either another conductor or a device that is grounded. Because of this, fuses (or) circuit breakers may trip as a result of the passage of excessive current that was not intended.

There is also the risk that the short circuit may cause other sections of the circuit to get energised, which will lead to the operation of additional components that were not intended to be activated. It is possible for a fuse (or0 circuit breaker to open simply due to “old age,” but in most cases, this is an indication that there is either an overcurrent or a short circuit.

3). Low Voltage Problems (Faults)

Relays that are experiencing difficulty due to low voltage may chatter or not respond at all. Motors and other components that include coils may generate abnormally high levels of heat, which can lead to the deterioration and even failure of the electrical insulation.

4). Over Voltage Problems (Faults)

Because of the increased level of heating caused by overvoltage issues, the lifetime of the majority of components is often reduced. The lighting and the motors are the systems that are most negatively impacted by this problem.

5). Electro-mechanical Problems (Faults)

Some other faults that occurs in electrical system:

- Wires that were in contact with one another.

- Insulation that has been damaged because of the presence of dirt or other extraneous things.

- There is either inadequate or excess time delay setting.

- Malfunctioning field device that is sending incorrect information to the logic.

- The potential of a contact being frozen also has to be taken into consideration, despite it happening with modern relays is quite rarely.

- Loose wire.

- Poor terminal contact.

- Defective coil (or) coil lead.

- Burnt out (blown) fuse.

6). Overamping

Overamping is yet another prevalent electrical problem. All electrical equipment is made to operate safely with a specific amount of current. Overamping occurs when a component receives current that exceeds the safe limit.

If a component gets too much current, it may be damaged. The data sheet contains the current limit for each component. Remember that the data sheet includes information about the part. It was created by the manufacturer.

To discover if a component is overamping, consult the data sheet. The data sheet will specify the maximum current which the component is designed to handle.

We will be employing a clamp multimeter to assess whether or not a component is overamping. Remember that a clamp multimeter features a claw on top. The claw is capable of measuring the current flowing via a wire inside it.

- Start by getting the clamp multimeter.

- Open the clampmeter’s jaws.

- Close the multimeter’s jaws and position the wire in the center of the clamp.

If the meter reads more current than the data sheet, the component is overamping. If a component receives too much current, it will overheat and fail.

When you see an overamplified component, it is likely damaged.

Ex: A blown fuse shows that the system was overloaded with current. You should look into why the system has too much current. Don’t simply replace the fuse.

Electrical Fault Identification

- Never neglect the power of smell for fault detection. The odor of “burnt insulation” usually indicates a malfunctioning component.

- Hearing strange sounds when operating an equipment can also indicate a problem.

- Checking components for visual evidence of burning and overheated equipment can potentially indicate problems. Be careful not to burn yourself checking hot equipment.

Procedure of Troubleshooting

Before starting to troubleshoot an electrical failure, make sure that organization’s safety standards and procedures. These should include the rules for lockout/tagout as well as the testing processes.

Understand the component of machinery is supposed to carry out its functions, and examine any relevant documentation, such as work orders, trouble-reports (or) conversations with the worker who first reported the issue. Then, proceed by following this methodical technique.

1). Observation

Check for noticeable cause that the equipment is not operating properly, such as components that are not securely fastened, parts that are located at the bottom of the panel, or indications that components are being overheated. Notice including sense of smell, hearing to detect any strange noises, and sense of touch to detect any excessive heat (or) loose components. Likewise, be sure to do comprehensive tests and operations on the equipment, if at all feasible, and make notes about what works well and what does not.

2). Define Problem Areas

Determine, based on observations, which components of the circuit are functioning normally and which ones are not. Any components of the circuit that are operating normally may be removed from the problematic sections to cut down on the amount of time spent testing in the future.

3). Identify Potential (Possible) Causes

After determining the nature of the issue at concern, list the potential causes. Identify the cause for the problem and their probability. In most conditions, the following elements would fall into the category of possibilities:

- Blown fuses,

- Mechanical components,

- Windings & coils,

- Terminal connections, and

- Wiring.

4). Test Probable Cause

Testing to be conducted from most possible cause, Always be aware of what to anticipate before taking a reading from the meters, and be aware of the implications of receiving a result that differs from what was projected. Based on the results of the testing, it’s possible that which is need to partition off more of the circuit to cut down on the problematic portion. Implement this method in identify a wire or component that seems unreliable.

5). Replace the Parts (Components) and Conduct Testing to Operate

If it has been established that a component is broken, the broken component must be replaced before the rest of the circuit may be taken through its tests. Check that all of the functions and features of the circuit are working properly. If everything is functioning as it should be, the equipment may be taken back into operation. If the circuit is still not functioning properly, it is necessary to re-evaluate the logic and start from the beginning of the process.

Electrical Troubleshooting Requires the use of Testing Equipment

Electrical testing may be performed using a wide variety of instruments.

1). Multimeter

A standard multimeter is required to carry out the majority of testing. A standard multimeter has the ability to measure alternating current (AC) voltage, direct current (DC) voltage, resistance, and small current flows.

2). Ohmmeter

An ohmmeter is a device that is used to measure resistance in a circuit. It is an extremely helpful instrument for locating open coils, broken light bulbs, and short circuits. Before taking a reading with an ohmmeter, power to the circuit has to be cut off and locked out. In addition, remember to connect the leads of the meter and take a reading in order to ensure that it is functioning properly before start the test. It is usually advisable to remove one connection wire from a circuit before taking a reading to verify that there are no parallel connections in reading. This may be done by removing one of the wires connecting the component.

3). Voltmeter

Voltmeters may measure either alternating current (AC) or direct current (DC), and they are the preferred instrument for locating open circuits. Before collecting any test readings, should always ensure that meter is functioning properly by testing it on a source of voltage that is already known. Maintain one of the leads as a reference lead & be sure to keep it on ground or neutral and should select the terminals for test points using the other lead.

4). Clamp meter

To monitor the amount of current drawn by components when are functioning, a clamp meter is an extremely useful tool. If a motor is consuming more current than usual, it might have old bearings or be operating at a higher than typical load. The clamp meter may also be used to determine how much current is flowing through the various components of a circuit.

Difference between fault finding and troubleshooting

| Fault Finding | Electrical Troubleshooting |

| The process of evaluating the functioning of a defective circuit in order to establish what the problem is with the circuit is referred to as “fault finding.” | Electrical troubleshooting involves recognizing the component or components that are malfunctioning and then fixing the circuit. The difficulty of the work of troubleshooting might greatly vary according to the type of equipment being analysed. |

Importance of electrical troubleshooting

When observe indicators of electrical arcing & burning or an equipment suddenly loses power, it is essential to locate the cause of the problem.

In most conditions, a faulty component is to responsible for an equipment failing to perform properly. The remaining components of the system all function exactly as designed.

Through the implementation of troubleshooting, can able to replace only the faulty component rather than the complete system.